Automobile precision stepped shaft outer circle grinding machining process

A technology of cylindrical grinding and processing technology, applied in the field of stepped shafts, which can solve the problems of affecting cutting, unable to eliminate the stress of stepped shafts, soft spots and high hardness, and achieve the effects of refining grains, eliminating structural defects, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

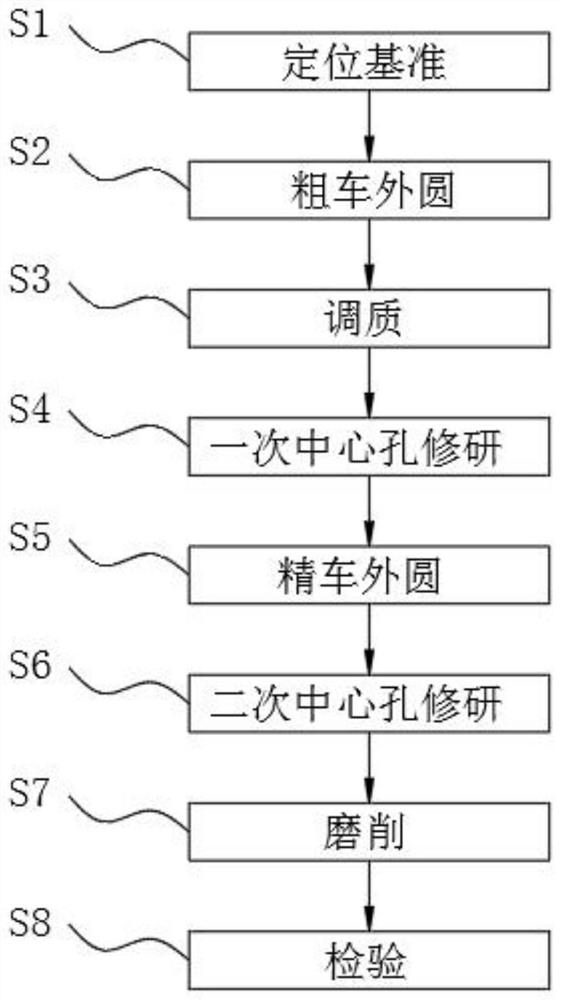

[0029] A process for machining the cylindrical grinding of precision stepped shafts for automobiles, comprising the following steps:

[0030] S1. Positioning reference: use a three-jaw self-centering chuck to clamp the outer circle of the hot-rolled steel blank, use the outer circle of the blank as a rough reference, first process an end face on the outer circle of the blank, and drill a center hole with a center drill. And the outer circle at one end is turned out, and then the outer circle that has been turned out is used as a reference, clamped with a three-jaw self-centering chuck, and then the other end face of the outer circle of the blank is processed, and another center hole is drilled to make the blank The center holes at both ends of the outer circle are located on the same horizontal axis;

[0031] S2. Rough turning of the outer circle: After the machining of the center hole of the outer circle of the blank is completed, use the top of the tailstock of the lathe to ...

Embodiment 2

[0046] A process for machining the cylindrical grinding of precision stepped shafts for automobiles, comprising the following steps:

[0047] S1. Positioning reference: use a three-jaw self-centering chuck to clamp the outer circle of the hot-rolled steel blank, use the outer circle of the blank as a rough reference, first process an end face on the outer circle of the blank, and drill a center hole with a center drill. And the outer circle at one end is turned out, and then the outer circle that has been turned out is used as a reference, clamped with a three-jaw self-centering chuck, and then the other end face of the outer circle of the blank is processed, and another center hole is drilled to make the blank The center holes at both ends of the outer circle are located on the same horizontal axis;

[0048] S2. Rough turning of the outer circle: After the machining of the center hole of the outer circle of the blank is completed, use the top of the tailstock of the lathe to ...

Embodiment 3

[0063] A process for machining the cylindrical grinding of precision stepped shafts for automobiles, comprising the following steps:

[0064] S1. Positioning reference: use a three-jaw self-centering chuck to clamp the outer circle of the hot-rolled steel blank, use the outer circle of the blank as a rough reference, first process an end face on the outer circle of the blank, and drill a center hole with a center drill. And the outer circle at one end is turned out, and then the outer circle that has been turned out is used as a reference, clamped with a three-jaw self-centering chuck, and then the other end face of the outer circle of the blank is processed, and another center hole is drilled to make the blank The center holes at both ends of the outer circle are located on the same horizontal axis;

[0065] S2. Rough turning of the outer circle: After the machining of the center hole of the outer circle of the blank is completed, use the top of the tailstock of the lathe to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com