Composite fiber emulsified asphalt mixture and preparation method thereof

A technology for emulsified asphalt and composite fibers, which is applied in the field of preparation of asphalt mixtures, can solve the problems of non-volatile, insufficient strength, and many bifurcations, and achieves the effects of improving fatigue resistance, high temperature performance, and many bifurcations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

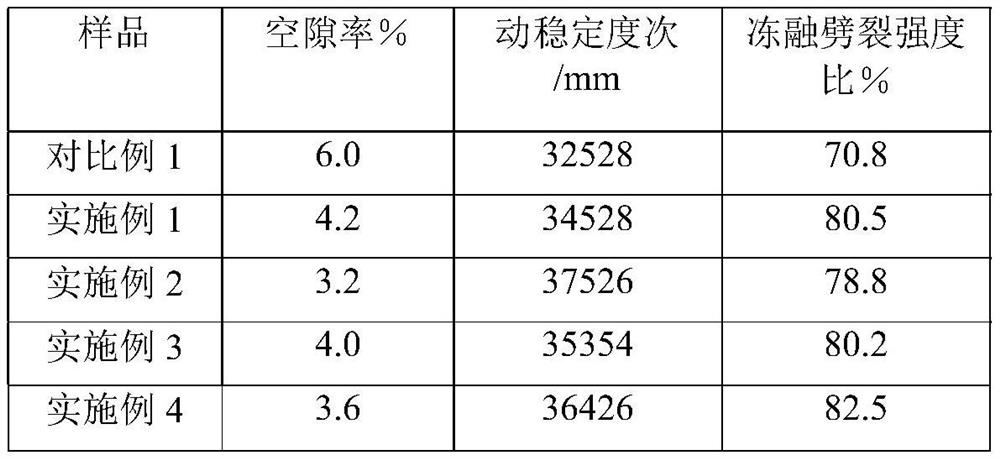

Embodiment 1-4 and comparative example 1

[0036] The percentages of various substances involved in the examples refer to mass percentages unless otherwise specified.

[0037] The determination of void ratio is calculated according to the formula described in "Test Regulations for Asphalt Asphalt Mixtures in Highway Engineering" JTG E20-2011" (T0705-4).

[0038] The determination of dynamic stability is tested according to the test standard of "Test Regulations for Asphalt Asphalt Mixtures in Highway Engineering" JTG E20-2011 (T0719-2011).

[0039] The determination of the freeze-thaw splitting strength ratio is carried out in accordance with the test standard JTG E20-2011 (T0729-2000) of "Test Regulations for Bituminous Asphalt Mixtures in Highway Engineering".

[0040] The compressive strength is tested by a computer-controlled electronic universal testing machine model CMT5305 at a loading speed of 50mm / min±5mm / min.

[0041] The composite fiber emulsified asphalt mixture of embodiment 1-4 adopts the following steps...

Embodiment 1

[0056] The preparation method of the composite fiber emulsified asphalt mixture of the present embodiment comprises the following steps:

[0057] Step S1: Weigh 5kg of aggregates according to the proportioning ratio. The gradation of the aggregates is selected as follows: aggregates with a particle size of 0-3 mm account for 16% of the total mass of the aggregate, and aggregates with a particle size of 5-10 mm account for 16% of the total mass of the aggregate. The mass percentage of the total mass of the aggregate is 36%, the mass percentage of the aggregate with a particle size of 10-15mm is 38%; the mass percentage of the mineral powder is 7.75% of the total mass of the aggregate, Pour 2.25% of the total mass of calcium hydroxide into the asphalt mixer, start the machine, and mix the aggregate with calcium oxide for 90 seconds;

[0058] Step S2: Then add 60g of water, start the machine, and stir evenly;

[0059] Step S3: Weigh 320g of emulsified asphalt and 14.6g of curing...

Embodiment 2

[0062] The preparation method of the composite fiber emulsified asphalt mixture of the present embodiment comprises the following steps:

[0063] Step S1: Weigh 5kg of aggregates according to the proportioning ratio. The gradation of the aggregates is selected as follows: aggregates with a particle size of 0-3mm account for 15% of the total mass of the aggregate, and aggregates with a particle size of 5-10mm account for 15% of the total mass of the aggregate. The mass percentage of the total mass of the aggregate is 40%, the mass percentage of the aggregate with a particle size of 10-15mm accounts for 35% of the total mass of the aggregate, the mass percentage of mineral powder accounts for the total mass of the aggregate is 7.5%. Pour 2.5% of the total mass of calcium hydroxide into the asphalt mixer, start the machine, and mix the aggregate with calcium oxide for 90 seconds;

[0064] Step S2: Then add 70g of water, start the machine, and mix well;

[0065] Step S3: Weigh 34...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com