Walnut protein isolate, preparation method thereof, phosphorylated walnut protein isolate, preparation method of phosphorylated walnut protein isolate, and food

A protein separation and phosphorylation technology, applied in the food field, can solve the problems of high technical and equipment requirements and high cost, and achieve the effects of simplifying the process, avoiding loss and damage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

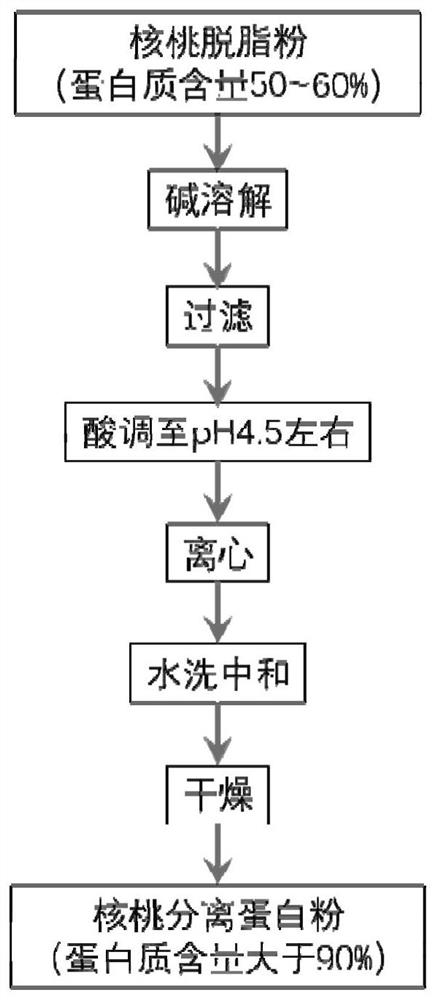

[0078] The present application proposes a preparation method of walnut protein isolate, which may include the following steps: leaching defatted walnuts with a salt solution.

[0079] Wherein, the protein content of the defatted walnut can be 50-60wt%.

[0080] In an optional embodiment, before leaching, the defatted walnuts can also be pulverized to obtain defatted walnut powder, so as to improve the leaching effect. Further, before soaking, the pulverized defatted walnuts can also be sieved, such as through a 60-100 mesh sieve.

[0081] In an optional embodiment, during leaching, the amount of salt solution and defatted walnuts can be 10-20mL: 1g, such as 10mL: 1g, 12mL: 1g, 15mL: 1g, 18mL: 1g or 20mL: 1g, etc., also Other solid-liquid ratios within the range of 10-20mL: 1g can be used.

[0082] In alternative embodiments, the saline solution may be an aqueous or buffered saline solution.

[0083] For reference, when the salt solution is an aqueous salt solution, the conc...

Embodiment 1

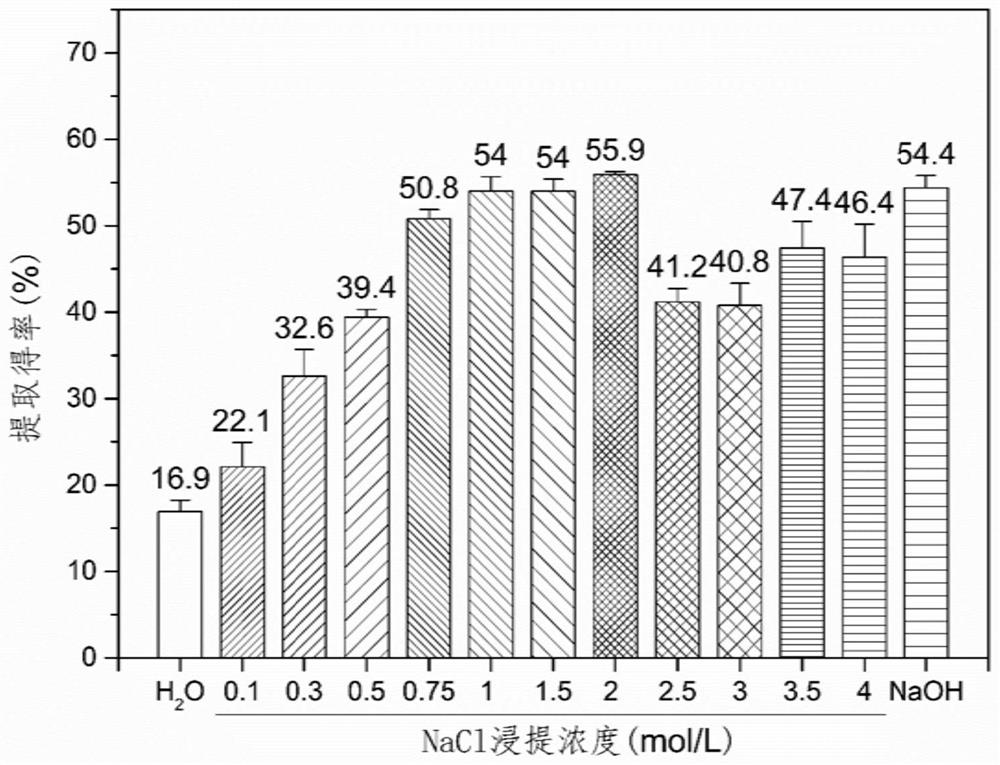

[0122] The method for preparing walnut protein isolate powder by leaching with different salt concentrations comprises the following steps:

[0123] After the walnuts are shelled, the walnut kernels are peeled and washed.

[0124] The walnut oil is extracted by cold pressing method or supercritical extraction technology, and the walnut pulp after deoiling is further extracted by n-hexane or petroleum ether and then dried to obtain defatted walnuts.

[0125] The defatted walnuts are pulverized with a pulverizer and passed through a 100-mesh sieve to obtain defatted walnut powder. Mix defatted walnut powder with NaCl concentration of 0.1, 0.3, 0.5, 0.75, 1, 1.5, 2, 2.5, 3, 3.5 and 4mol / L aqueous solution or pure water according to the mass-volume ratio of material to liquid in the ratio of 1g:20mL Uniformly, placed at 25 ° C for 1 hour shaking extraction.

[0126] Solid-liquid separation: Centrifuge the extract at 10,000 g for 30 minutes at room temperature to remove insoluble...

Embodiment 2

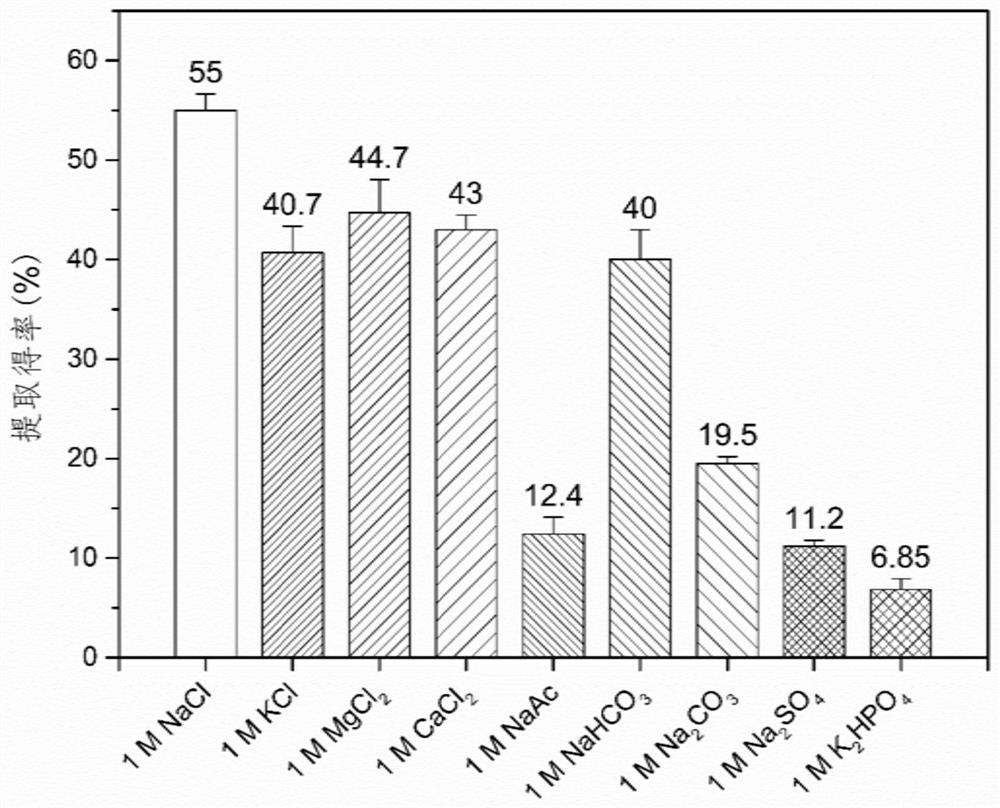

[0132] The method for preparing walnut protein isolate powder by extracting different types of salts comprises the following steps:

[0133] After the walnuts are shelled, the walnut kernels are peeled and washed.

[0134] Walnut oil is extracted by cold pressing or supercritical extraction technology, and the deoiled walnut meal is further extracted with n-hexane or petroleum ether to degrease and dry to obtain defatted walnuts.

[0135] The defatted walnuts are pulverized by a pulverizer and passed through a 100-mesh sieve to obtain defatted walnut powder. Mix defatted walnut powder with 1mol / L NaCl, KCl, MgCl 2 , CaCl 2 , NaAc, NaHCO 3 、Na 2 CO 3 、Na 2 SO 4 and K 2 HPO 4 The aqueous solution was mixed evenly at a ratio of 1g:20mL according to the mass-to-volume ratio of the material to liquid, and placed at 25°C for oscillating extraction for 1 hour.

[0136] Solid-liquid separation: Centrifuge the extract at 10,000 g for 30 minutes at room temperature to remove i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com