A kind of environment-friendly liquid polyurethane curing agent and application method thereof

A technology of liquid polyurethane and its application method, which is applied in the environment-friendly liquid polyurethane curing agent and its application field, can solve the problems of excessive smoke and generation of toxic and irritating gas, and achieve the effect of reducing the pressure on the environment and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: A kind of environment-friendly liquid polyurethane curing agent and its application method

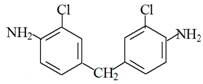

[0020] A method for recycling 3,3'-dichloro-4,4'-diaminodiphenylmethane (MOCA) by-products, the 3,3'-dichloro-4,4'-diaminodiphenylmethane The by-products are dissolved in polyols to obtain an environmentally friendly liquid curing agent, which is used to cure one component of a solvent-free two-component polyurethane system at room temperature.

[0021] 3,3'-dichloro-4,4'-diaminodiphenylmethane by-product (MOCA by-product) mainly comes from polymers formed during the production process, free of mechanical impurities and liquid by-products. And it does not contain harmful ingredients such as free o-chloroaniline (that is, free amine), and it is odorless. The mass fraction ranges from 20% to 70%, preferably 30% to 60%. This embodiment is specifically 45%.

[0022] Polyols are polyether polyols and small molecule polyols with a functionality of 2 to 3, of which pol...

Embodiment 2

[0049] Embodiment 2: A kind of environment-friendly liquid polyurethane curing agent and its application method

[0050] The formula of the liquid polyurethane curing agent is: 120g of MOCA waste (amine value 414 mgKOH / g), 120g of MOCA by-product (amine value 393 mgKOH / g), 160g of polyoxypropylene glycol PPG-600, and 83 g of catalyst Valikat ZB.

[0051] The solid raw materials were dissolved according to the process conditions of Example 1 to obtain a liquid polyurethane curing agent, the measured moisture content was 0.06%, and the total calculated equivalent weight of amino groups and hydroxyl groups was 176.

Embodiment 3

[0052] Embodiment 3: A kind of environment-friendly liquid polyurethane curing agent and its application method

[0053] The formula of liquid polyurethane curing agent is: MOCA by-product (amine value 416 mgKOH / g) 160 g, polyoxypropylene diol PPG-1000 160 g, polyoxypropylene triol N-303 80 g, catalyst BX-EM23 4 g.

[0054] The solid raw materials were dissolved according to the process conditions of Example 1, and additives were added to obtain a liquid polyurethane curing agent, and the measured moisture content was 0.075%. The total calculated equivalent weight of amino group and hydroxyl group is 173.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com