High-frequency ultrasonic pulse generator and optimization method

A pulse generator, ultrasonic pulse technology, applied in pulse generation, pulse technology, electrical components, etc., can solve the problems of limited pulse amplitude and pulse power of a single avalanche tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

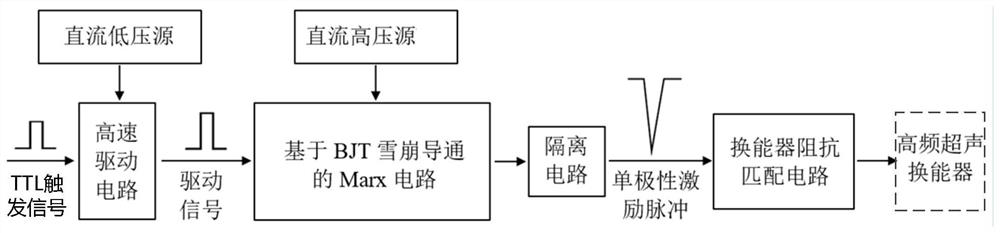

[0056] build as figure 1 The high-frequency ultrasonic pulse generator shown includes a DC low-voltage source, a DC high-voltage source, a high-speed drive circuit, a Marx circuit, an isolation circuit and a transducer impedance matching circuit.

[0057] The DC low-voltage source provides the working voltage V to the high-speed drive circuit DD .

[0058] The DC high voltage source provides the Marx circuit with avalanche breakdown voltage BV close to the BJT in the Marx circuit CES The supply voltage V CC .

[0059] The high-speed driving circuit is composed of 4 inverting Schmitt triggers in series, which receive the TTL trigger signal, convert the TTL trigger signal into a driving signal and send it to the Marx circuit. Such as Figure 6 As shown, the high-speed drive circuit uses the 74AHCT14D chip, which is a high-speed silicon gate CMOS device, and can provide up to six inversion buffers with Schmitt trigger functions.

[0060] The Marx circuit consists of a 5-lev...

Embodiment 2

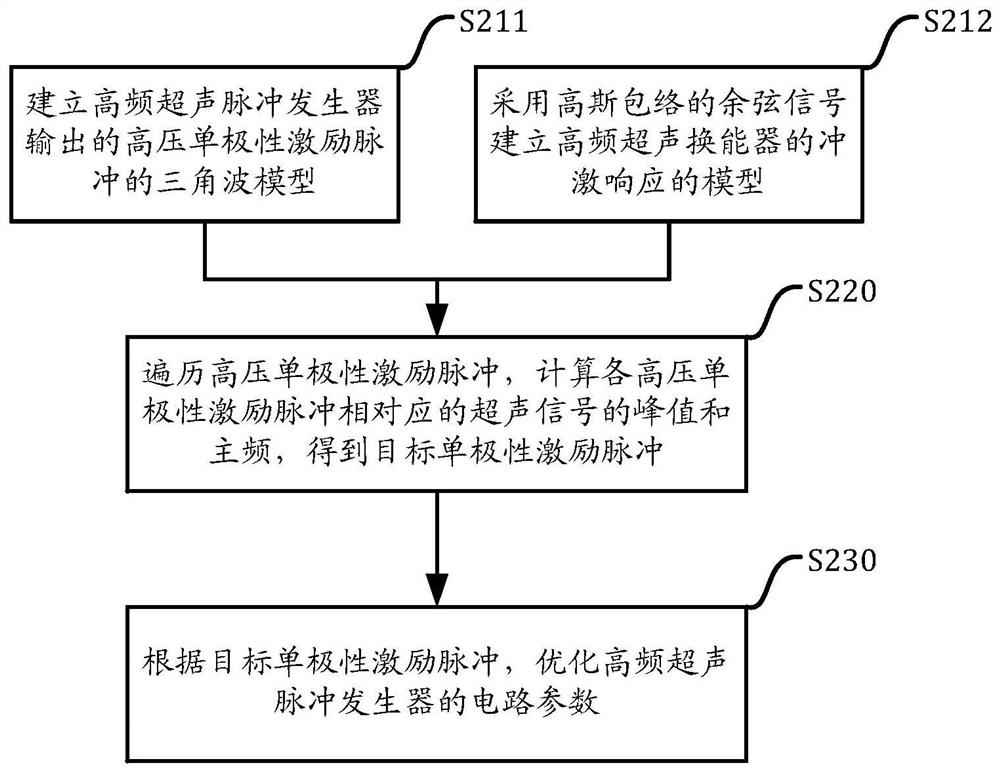

[0066] use as figure 2 The shown method optimizes the high-frequency ultrasonic pulse generator of the first embodiment. It is determined that the load connected in parallel with the parallel capacitor C is a 200MHz high-frequency ultrasonic transducer. After testing, the center frequency f of the high-frequency ultrasonic transducer is 0 It is 177.5MHz, and the relative bandwidth B is 0.726.

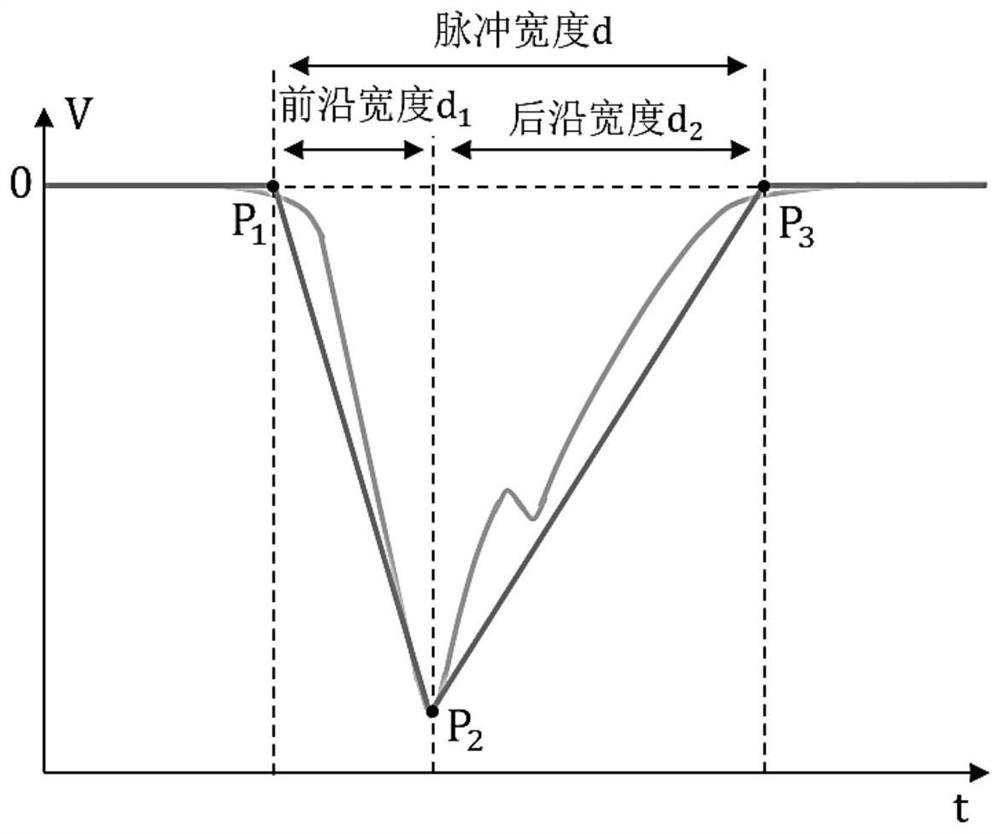

[0067] According to the center frequency f of the high frequency ultrasonic transducer 0 , determine the pulse width d=0.766 / f of the target unipolar excitation pulse 0 = 4.315 ns. and when d 1 = d 2 =2.158ns, the peak value of the ultrasonic signal is the largest. At this time, the peak frequency of the ultrasonic signal f m close to the transducer center frequency f 0 (i.e. f 0 -f m 0 ), the ultrasonic signal has the optimal peak value and peak frequency.

[0068] According to formula 3 get: d 1 =1.24×2 / (2πf T ) = 2.158 ns. From this we get the BJT characteristic freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com