Polyamic acid, polyamic acid solution, polyimide, polyimide film, laminate and flexible device, and method for producing polyimide film

A polyimide film and polyamic acid technology, which is applied in the fields of polyimide film, polyamic acid, polyamic acid solution, and polyimide, can solve the problems of component damage, substrate warpage, etc. Excellent thermal dimensional stability and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

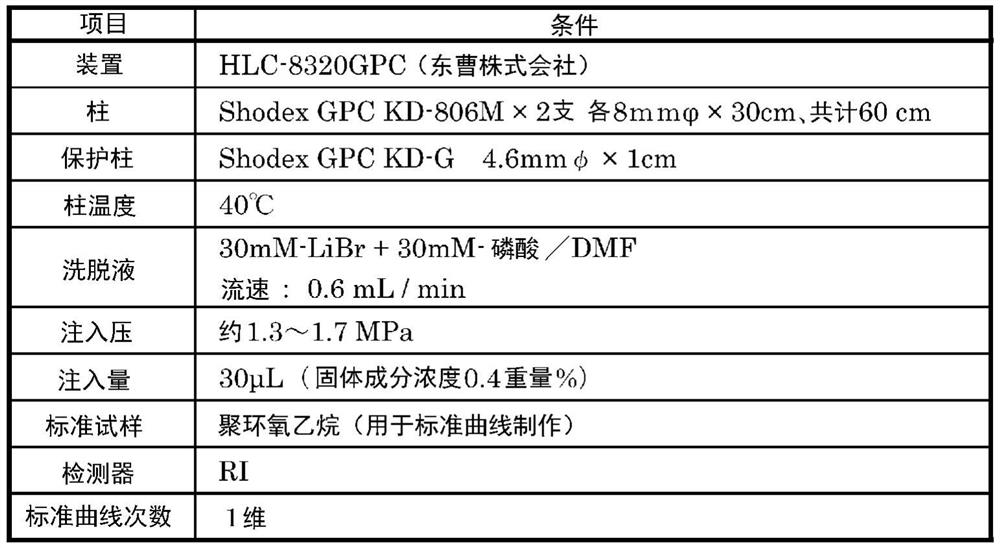

Method used

Image

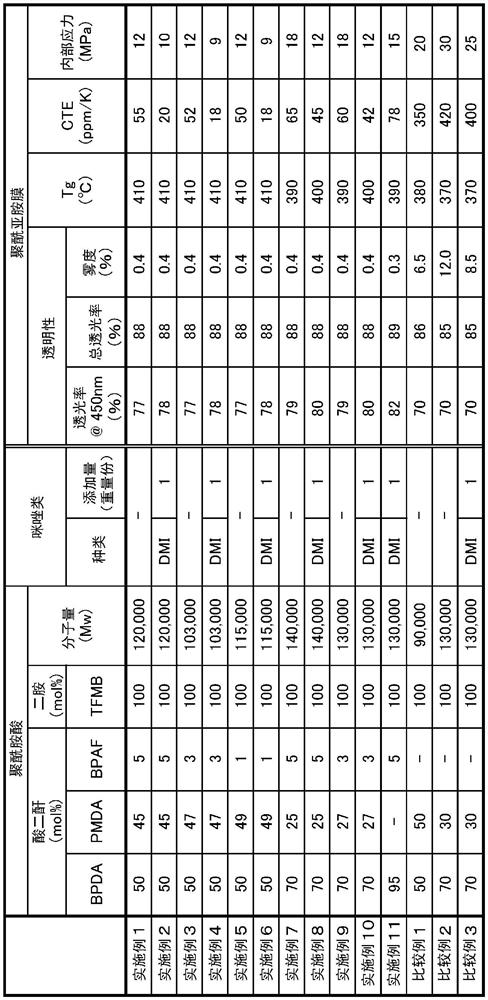

Examples

preparation example Construction

[0043] The preparation method of the polyamic acid solution containing imidazoles is not particularly limited. Imidazoles may be added to a polyamic acid solution obtained by polymerization of tetracarboxylic dianhydride and diamine in an organic solvent, or imidazoles may be added to a solution before or during the polymerization reaction. When imidazoles are contained in the reaction system, tetracarboxylic dianhydride may ring-open and the reactivity with diamine may fall. Therefore, the method of adding imidazoles to the polyamic-acid solution obtained by superposition|polymerization of tetracarboxylic dianhydride and diamine is preferable from a viewpoint of the molecular weight control of polyamic acid. The imidazoles may be directly added to the polyamic acid, or the imidazoles previously mixed with a solvent may be added to the polyamic acid.

[0044] Various organic or inorganic low-molecular or high-molecular compounds can be compounded in order to impart processabi...

Embodiment 1

[0087] 400.00 g of N-methyl-2-pyrrolidone (hereinafter referred to as NMP) and 54.42 g of TFMB were put into a 2 L separable glass flask equipped with a stirrer equipped with a stainless steel stirring rod and a nitrogen introduction tube, and stirred until After the dissolution, stirring the solution, 25.00 g of BPDA, 16.68 g of PMDA, and 3.90 g of BPAF were added in this order, and stirred for 24 hours to obtain a polyamic acid solution. The input concentration of the diamine component and the tetracarboxylic dianhydride component in this reaction solution was 20.0 weight% with respect to the reaction solution whole quantity.

Embodiment 2

[0089]To 500 g of a 20.0% by weight polyamic acid solution synthesized in the same manner as in Example 1, 1 g of 1,2-dimethylimidazole (hereinafter sometimes referred to as DMI) was added (1 part by weight, 100 parts by weight of polyamic acid, The polyamic-acid solution was prepared with respect to 1 mol of amide groups of a polyamic acid (0.03 mol).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com