Ink and preparation method thereof

A technology of ink and mixing equipment, applied in the field of ink, can solve the problems of poor grinding quality of raw materials, uneven printing, poor adhesion, etc., and achieve the effects of enhancing adhesion, avoiding uneven printing, and reducing the probability of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

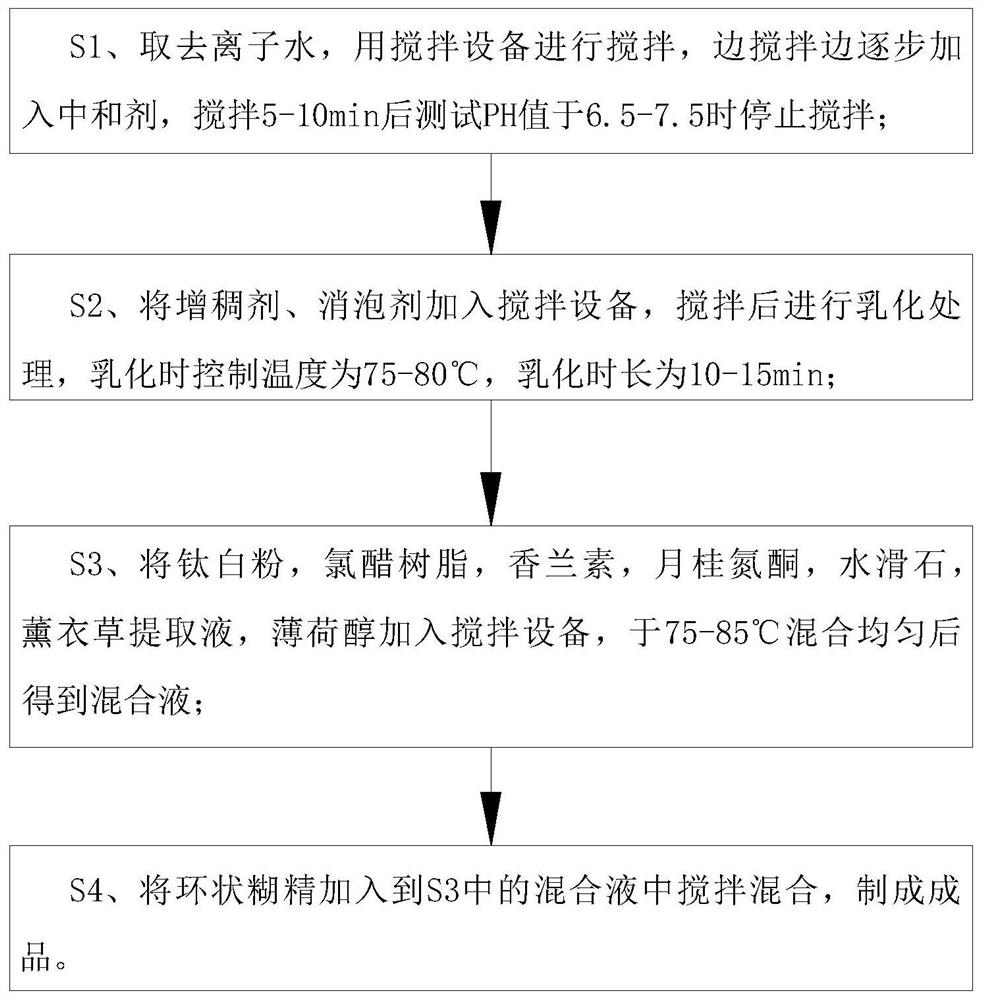

Method used

Image

Examples

Embodiment approach

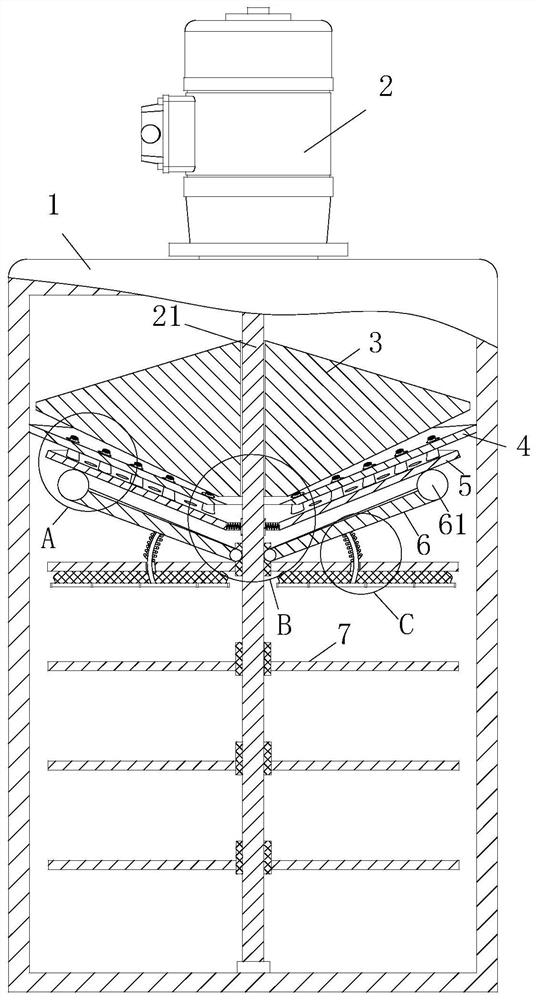

[0048] As an embodiment of the present invention, the grinding gap 31 gradually becomes smaller from top to bottom, and the grinding disc 4 is provided with a plurality of vertically penetrating first blanking holes 41 at intervals from top to bottom. Through the setting of the first blanking hole 41, the raw materials meeting the particle size requirements can be discharged in time, avoiding heat accumulation caused by excessive grinding of raw materials, preventing the neutralizing agent from being decomposed by high temperature, and ensuring the quality of the finished ink.

[0049] As an embodiment of the present invention, an adjustment disc 5 matching its shape is arranged below the grinding disc 4 , and the upper end surface of the adjustment disc 5 is fixedly provided with a plurality of sets of tops that can move up to the first blanking hole 41 . Rod 51, a plurality of second blanking holes 53 penetrating up and down are evenly distributed on the adjusting disc 5; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com