Anti-pollution antibacterial reverse osmosis membrane as well as preparation method and application thereof

A reverse osmosis membrane and anti-pollution technology, applied in the field of reverse osmosis, can solve the problems of anti-pollution and insufficient antibacterial ability, and achieve the effect of reducing the adhesion of pollutants, not easy to lose, and strong hydrophilic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

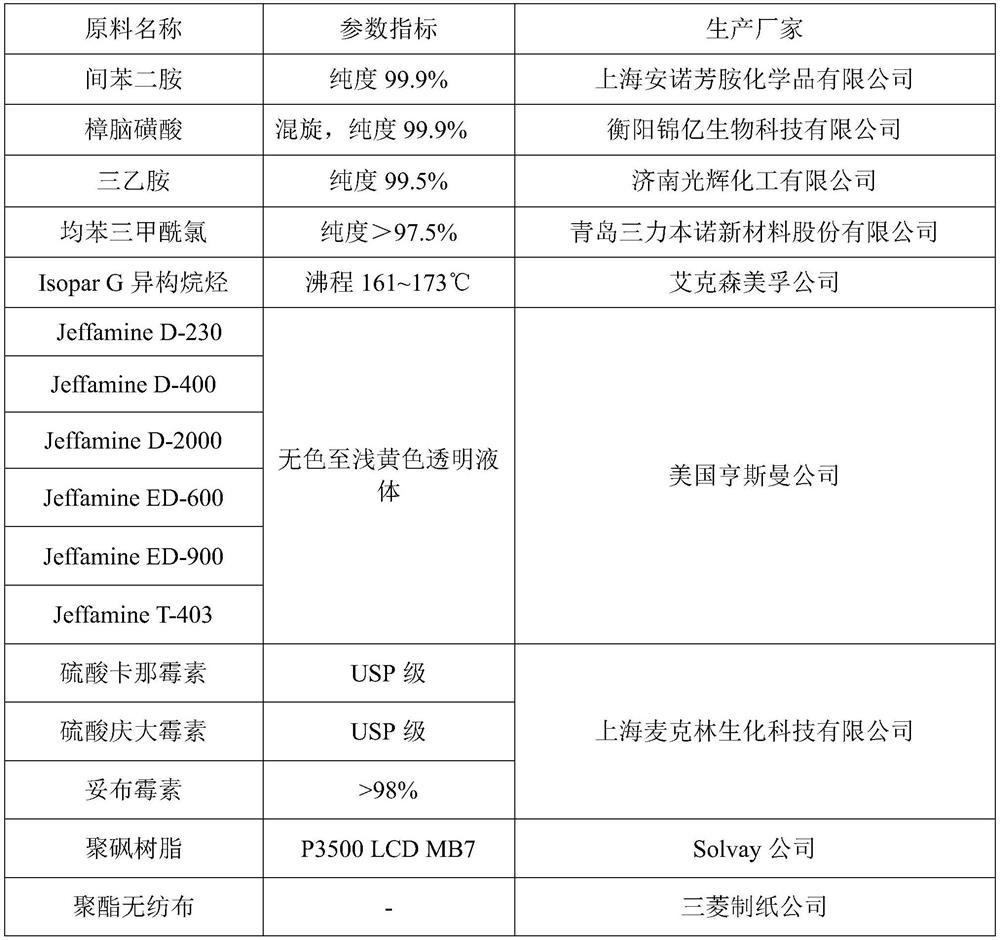

preparation example Construction

[0033] Specifically, the preparation method of the anti-pollution and antibacterial reverse osmosis membrane of the present invention comprises the following steps:

[0034] (1) Immerse the polysulfone ultrafiltration membrane in the prepared first aqueous phase solution containing multifunctional amine, keep it for 10-300 seconds, and remove the residual first aqueous phase on the surface of the polysulfone ultrafiltration membrane with a squeeze roller after taking it out solution.

[0035] (2) Then pour the prepared organic phase solution containing polybasic acid chloride on the surface of polysulfone ultrafiltration membrane for interfacial polymerization reaction, keep it for 5-120 seconds, pour off the organic phase solution, and use air knife or air knife to evenly Purge until there is no residual solvent on the surface of the membrane to form a nascent reverse osmosis membrane with the first polyamide layer.

[0036] (3) Pour the prepared second aqueous phase solutio...

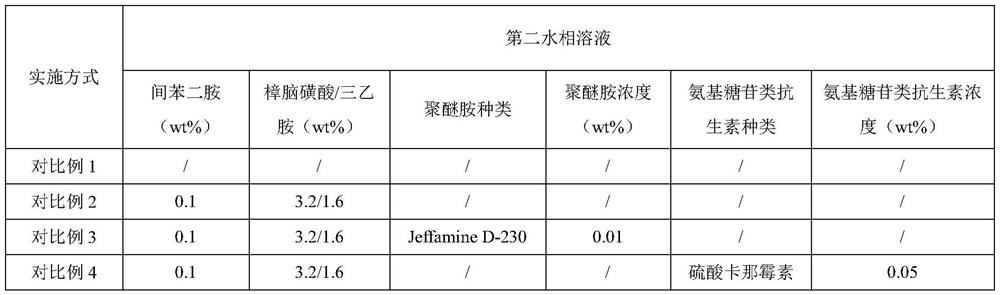

Embodiment 1

[0079] The anti-pollution and antibacterial reverse osmosis membrane was prepared by the preparation process in Comparative Example 1. The difference is that in Step 5, after the interface polymerization is evenly blown by the air knife until there is no residual solvent on the surface of the membrane, the mass percentage of m-phenylenediamine is 0.1%, the mass percentage of camphorsulfonic acid is 3.2%, and three The mass percentage of ethylamine is 1.6%, the mass percentage of polyetheramine D-230 is 0.01%, and the mass percentage of kanamycin sulfate is 0.05%. The second aqueous phase solution is subjected to secondary interfacial polymerization, and the reaction time is 30s. After removing the second aqueous phase solution, put it in an oven at 80°C for heat treatment for 6 minutes, and finally remove the membrane and wash it with water to obtain anti-pollution and antibacterial reverse osmosis modified by polyetheramine D-230 and kanamycin membrane.

Embodiment 2

[0081] The anti-pollution and antibacterial reverse osmosis membrane was prepared by the preparation process in Example 1. The difference is that the mass percentage of polyetheramine D-230 in the second aqueous phase solution is changed to 0.1%, and the mass percentages of m-phenylenediamine, triethylamine, camphorsulfonic acid and kanamycin sulfate remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com