Paint spraying device for guitar panel production

A panel and guitar technology, which is applied in the field of painting equipment for guitar panel production, can solve the problems of inability to guarantee the uniformity of paint spraying, inapplicability and mass production, and low work efficiency, so as to save spraying production time and ensure uniformity of painting , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

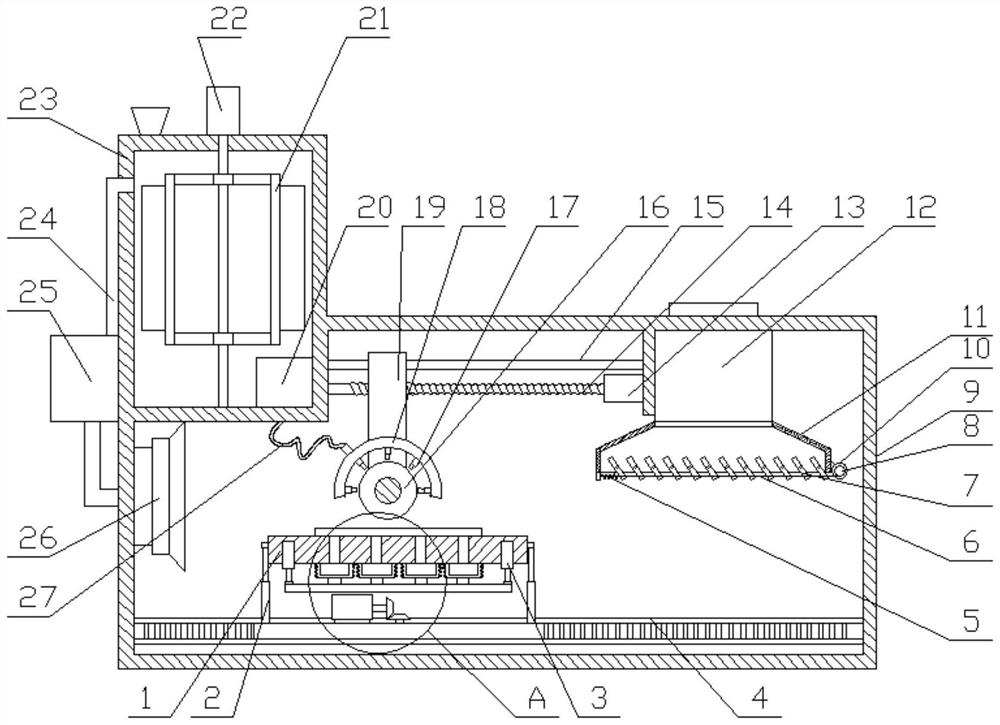

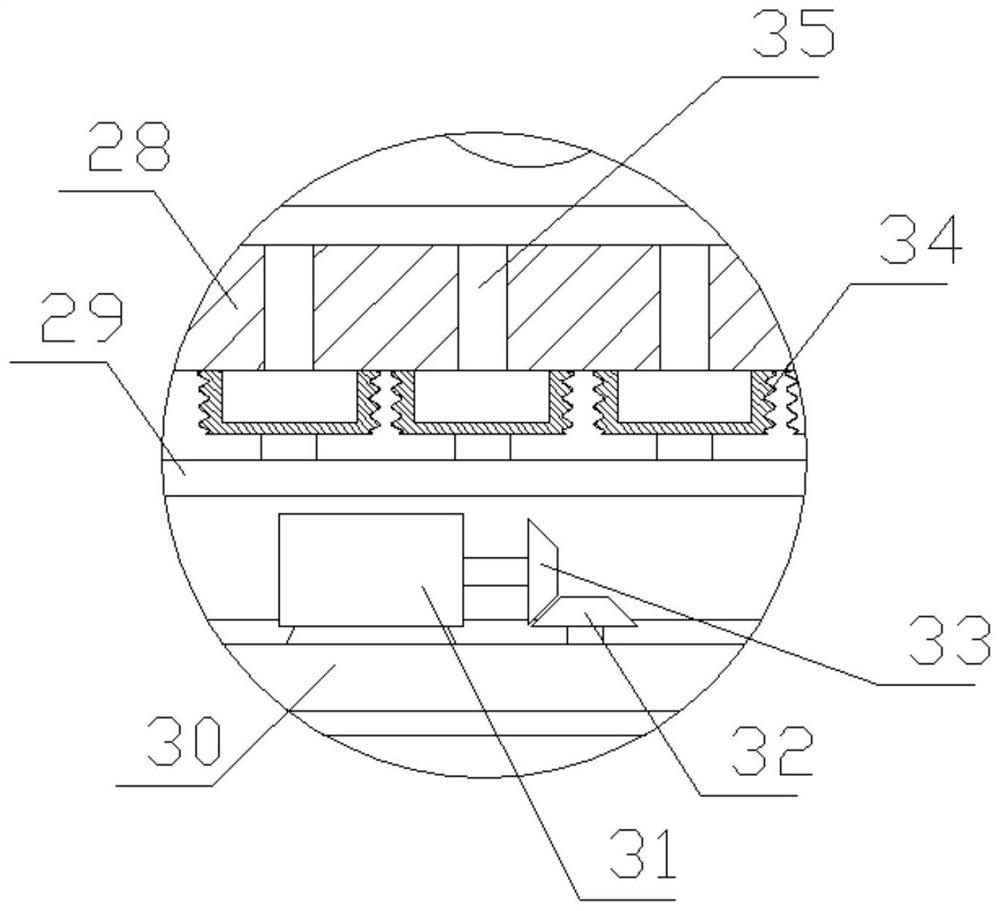

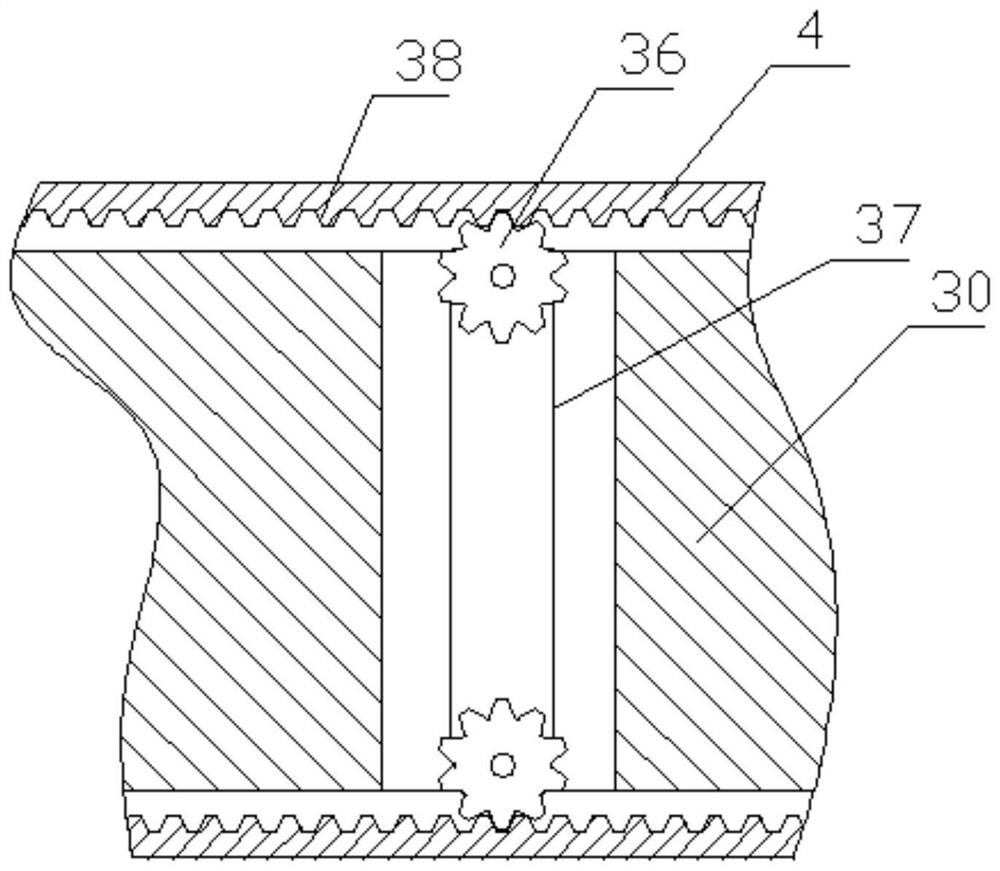

[0024] see Figure 1-3 , a painting device for guitar panel production, comprising a first motor 10, a second motor 13, a third motor 22, a fourth motor 31, a wind compressor 25, a blower fan 12 and a casing 9, the output end of the fourth motor 31 The second bevel gear 33 is fixedly connected, and the second bevel gear 33 meshes with the first bevel gear 32. The lower side of the box body 9 is provided with a running mechanism, and the running mechanism includes a walkway 4, and a cog rail 38 is arranged inside the walkway 4 on the front and rear sides. , the rack gear 38 meshes to connect the spur gear 36, the spur gear 36 rotates and connects to the inner cavity of the base 30, the upper end of the spur gear 36 is fixedly connected to the first bevel gear 32, and the lower side of the spur gear 36 on the front and rear sides is provided with a pulley, between the pulleys A synchronous belt 37 is set, and the synchronous rotation of the horizontal gears 36 on both sides is r...

Embodiment 2

[0027] see figure 1 The difference between this implementation and the above-mentioned embodiment 1 is that the left side of the box body 9 is provided with an air compressor 25, the lower side of the air compressor 25 is connected to the suction hood 26, and the upper side of the air compressor 25 is provided with a paint return pipe 24 , the paint return pipe 24 pipelines are connected to the paint mixing tank 23, and the air compressor 25 is set to extract the internal paint gas, and reclaim the paint gas to prevent waste.

[0028]The working principle of the present invention is: said a kind of painting device for guitar panel production, when using this device for guitar panel topcoat spraying, first turn on the third motor 22 . The third motor 22 drives the stirring shaft 21 to rotate to stir the paint, then the guitar panel is placed on the support platform 28, and the second telescopic cylinder 3 is controlled to drive the supporting plate 29 to move downward, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com