Implementation method for full-automatic testing of power equipment

A technology for fully automatic testing and power equipment, applied in automated testing systems, electronic circuit testing, sorting, etc., to solve problems such as high error rates and large labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments.

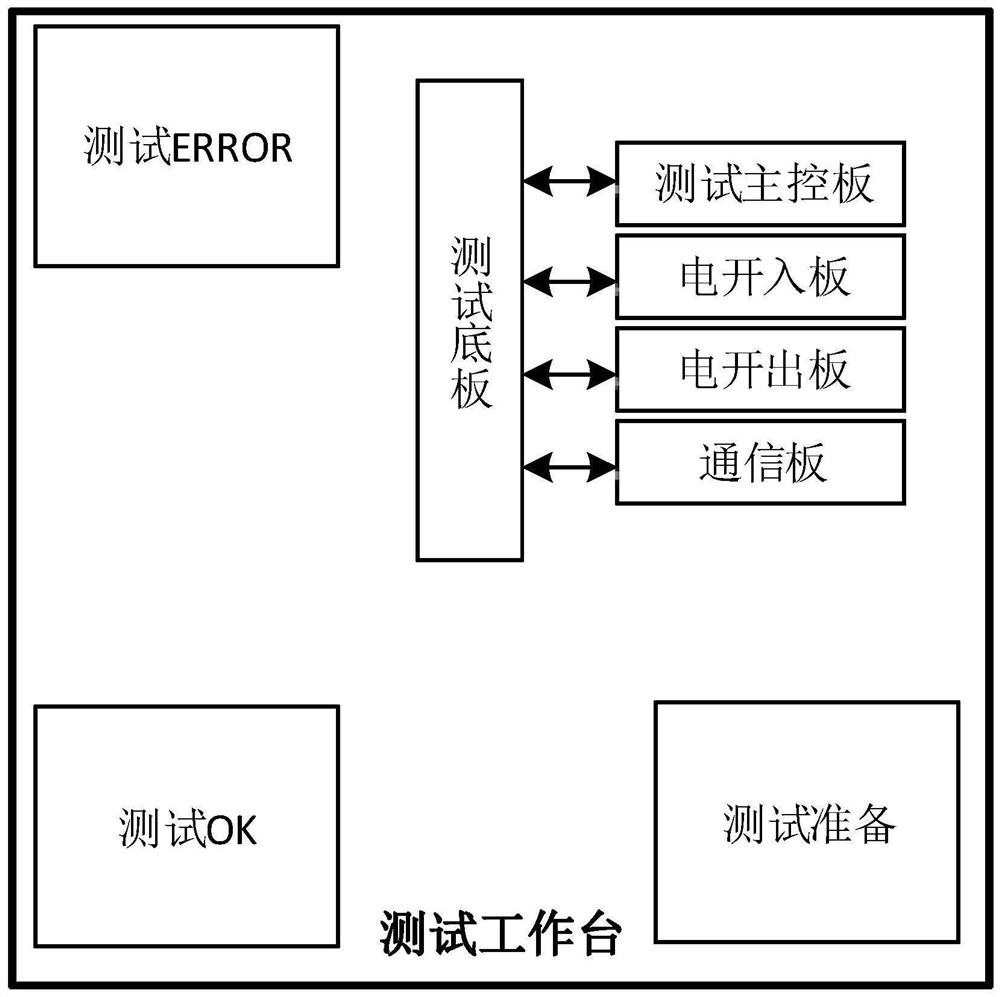

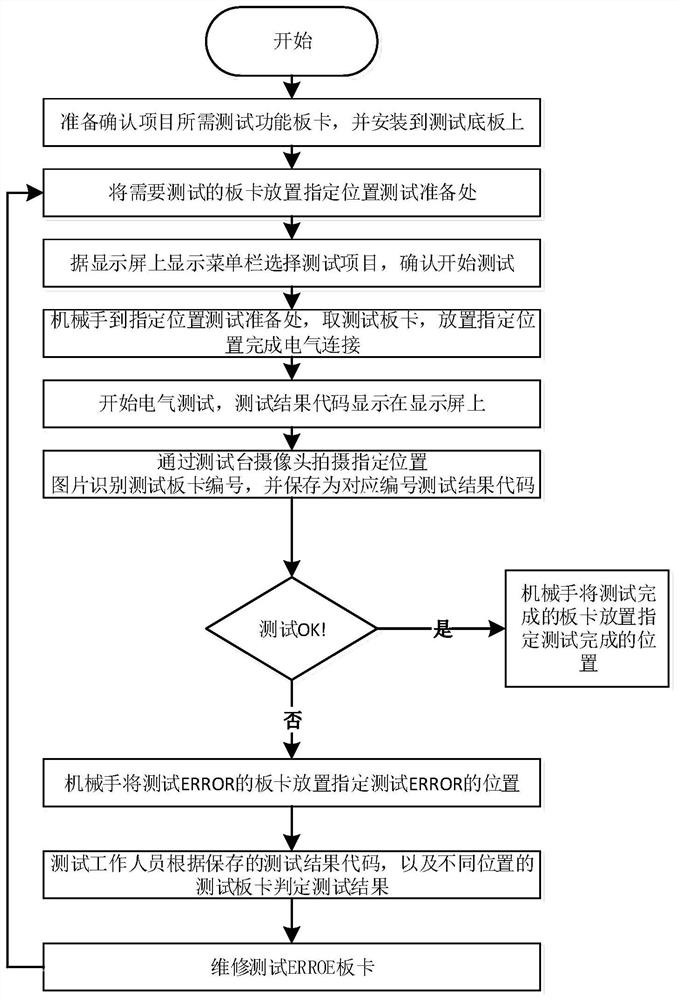

[0021] refer to figure 1 and figure 2 As shown, the implementation system for fully automatic testing of electrical equipment in this embodiment includes a control device, a test bench, a test base, a test function board, a manipulator, a display screen, a camera, and at least one board to be tested.

[0022] Among them, the test platform is equipped with a test base board, and the test function board can be installed on the test base board. The selection of the test function board is confirmed according to the test requirements of the specific project (different test function boards are selected for different projects, and multi-project joint testing and multi-project sharing are realized. Test Bench);

[0023] The test bench is equipped with a test preparation area, an electrical test area, a test result ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com