Cast-in-place pile for enhancing bearing strength of deep miscellaneous fill area and construction method

A technology of bearing strength and miscellaneous filling, applied in sheet pile walls, foundation structure engineering, protection devices, etc., can solve problems such as accelerated corrosion efficiency, engineering safety hazards, and reduced bearing strength of cast-in-place piles, so as to reduce porosity and reduce Potential safety hazards, good synergistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

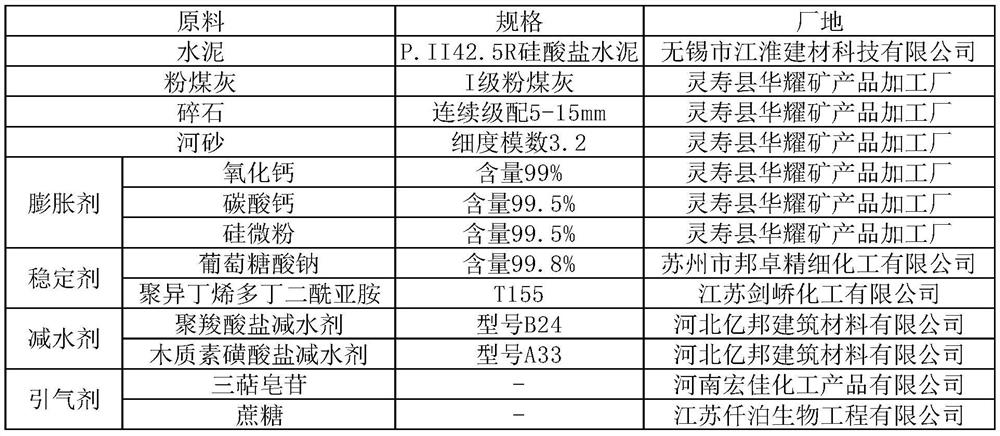

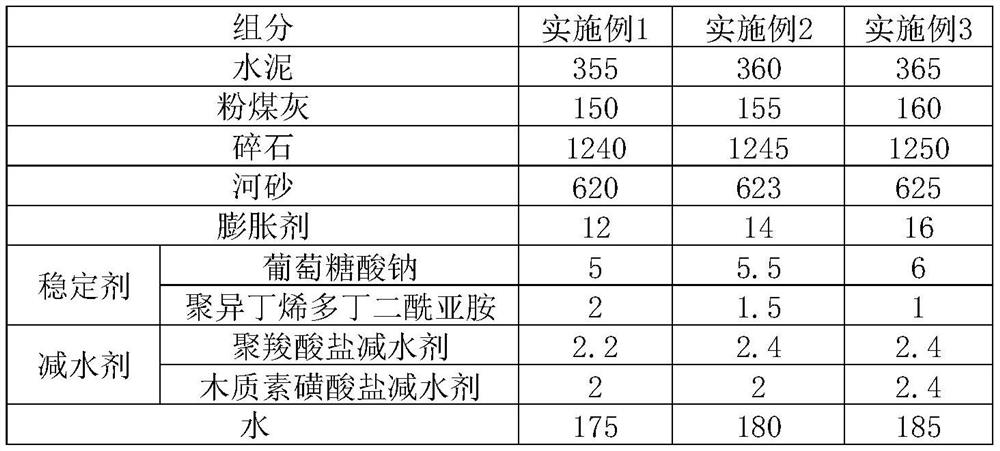

[0053] The components and proportions of the expansion agent in Preparation Examples 1-3 are shown in Table 2 below.

preparation example 1

[0057] A kind of expansion agent, its preparation method is as follows:

[0058] Step 1, prepare calcium oxide, calcium carbonate and silicon micropowder according to the proportioning in table 2 and evenly mix to obtain premixture;

[0059] Step 2, after the pre-mixture is sent into the ball mill and milled at a ball milling speed of 650rad / min for 2h, the ball milling speed of the ball mill is increased to 800rad / min, and ball milling is continued for 30min to obtain an intermediate mixture;

[0060] Step 3, drying and crushing the intermediate mixture to obtain an expanding agent with a particle size of ≤100 μm.

preparation example 2

[0062] A kind of expansion agent, and the difference of preparation example 1 is:

[0063] Step 2: Send the pre-mixture into a ball mill and mill at a ball milling speed of 550 rad / min for 2.5 hours, then increase the ball milling speed to 850 rad / min, and continue ball milling for 25 minutes to obtain an intermediate mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com