Preparation method of thermoplastic polyurethane elastomer

A thermoplastic polyurethane and elastomer technology, applied in the field of polymer preparation, can solve the problems of heat transfer efficiency reduction, side reactions, prolonging operation time, etc., and achieve the effect of prolonging the prefabrication time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

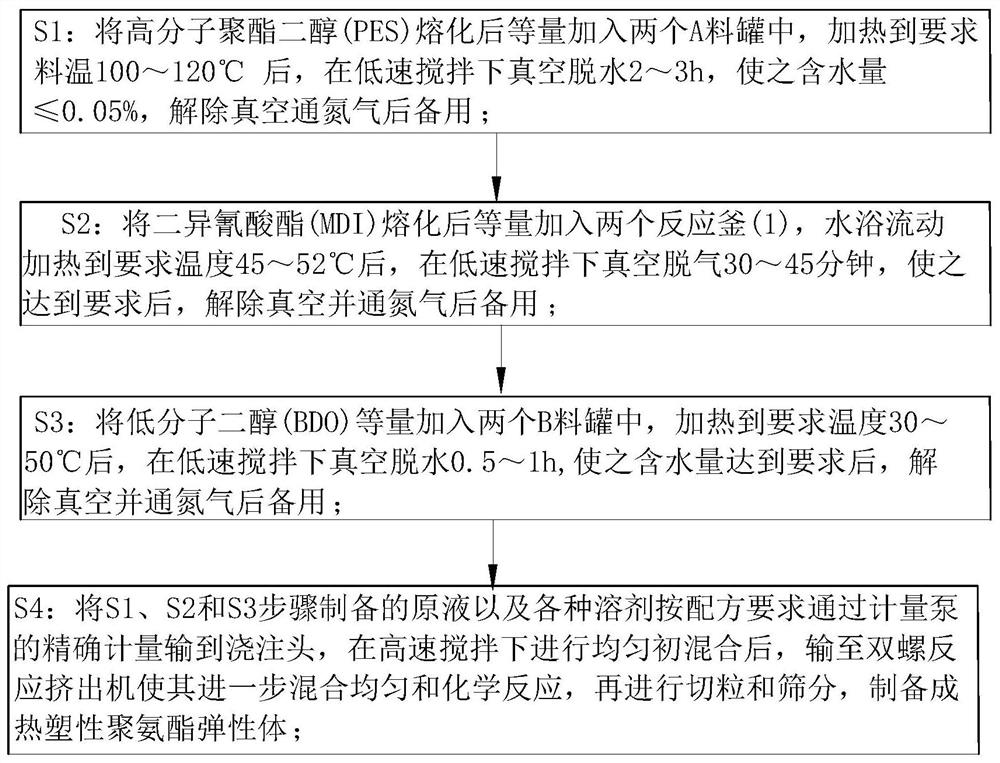

[0036] like Figure 1-Figure 5 Shown, the preparation method of a kind of thermoplastic polyurethane elastomer of the present invention, this method comprises the steps:

[0037] S1: Melt the polymer polyester diol (PES) and add the same amount to the two material tanks A, heat to the required material temperature of 100-120°C, and vacuum dehydrate for 2-3 hours under low-speed stirring to make the water content ≤ 0.05%, ready for use after releasing the vacuum and venting nitrogen;

[0038] S2: Melt the diisocyanate (MDI) and add the same amount to two reaction kettles 1, heat it in a water bath to the required temperature of 45-52°C, and degas it under vacuum for 30-45 minutes under low-speed stirring to make it meet the requirements. Vacuum and pass nitrogen for standby; heat the diisocyanate in the reactor 1 by means of water bath flow heating, which can improve the efficiency of vacuum degassing of diisocyanate after heating;

[0039] S3: Add low-molecular-weight diol (...

Embodiment approach

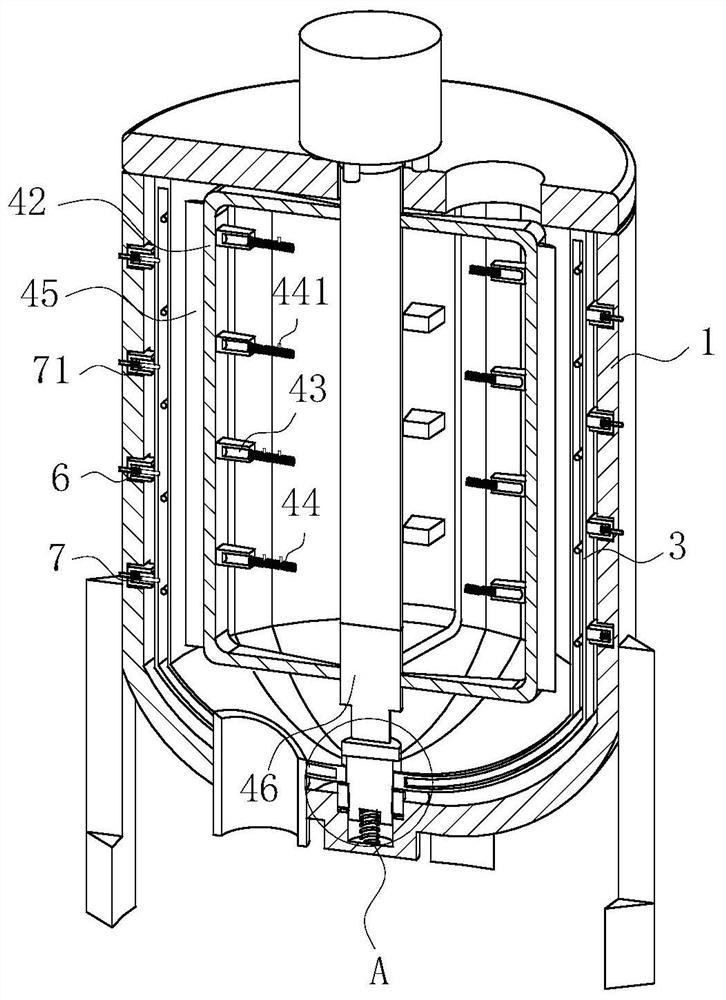

[0043] As an embodiment of the present invention, the stirring drive mechanism includes a stirring shaft 41, a U-shaped stirring frame 42, a stirring column 43, a spiral stirring bar 44, a scraper blade 45 and an electric telescopic rod 46; the stirring shaft 41 is rotated and inserted In the inner kettle body 3, and the top of the stirring shaft 41 extends out of the outer kettle body 2 and is connected to the output end of the drive motor, and the driving motor is fixed to the top of the outer kettle body 2; the outer wall of the stirring shaft 41 is evenly fixed in the circumferential direction A plurality of U-shaped stirring racks 42, and the inner wall of the vertical bar 421 of the U-shaped stirring rack 42 is provided with a plurality of stirring columns 43; the ends of a plurality of said stirring columns 43 are all provided with a spiral stirring bar 44; The outer wall vertical direction of straight bar 421 is provided with scraper blade 45, and scraper blade 45 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com