Bypass type gas-liquid separation type geothermal energy productivity testing system

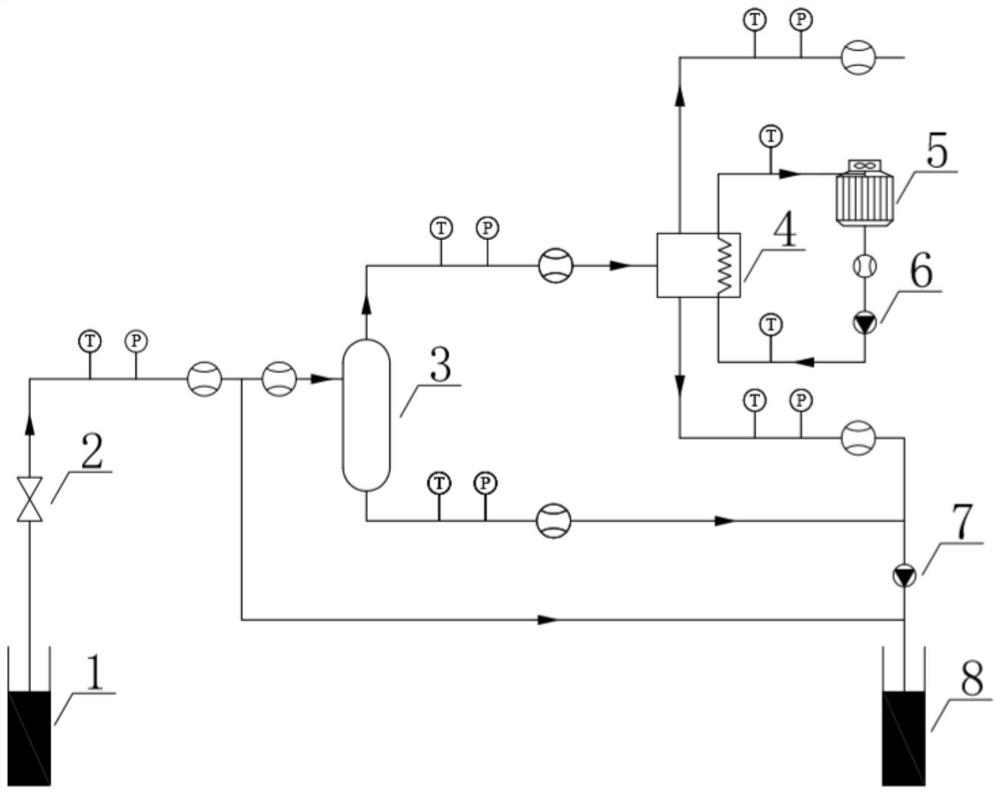

A testing system, gas-liquid separation technology, applied in geothermal energy systems, geothermal energy prediction/simulation, geothermal energy, etc., can solve problems such as uncertainty, large differences in thermophysical parameters and thermodynamic properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Taking the Yangyidi thermal power station in Tibet as an example, the heat-carrying fluid of dry hot rock produced at the wellhead of production well 1 is tested by adjusting the opening of the wellhead valve 2 and reducing the total flow rate by 10% each time. Adjust the time interval according to the on-site test situation, and reduce it in turn until it reaches 30% of the total flow, and complete the variable working condition test.

[0028] Through the test results of different flow rates, it is finally calculated that the temperature of the hot dry rock heat-carrying fluid produced at the wellhead of production well 1 is 168°C, and the pressure is 0.76PMa. The geothermal water, geothermal water steam and The flow rates of non-condensable gases are 581.3m 3 / s, 42.74m 3 / s and 0.96m 3 / s, and then the proportions of geothermal water, geothermal steam and non-condensable gas are 93%, 6.846% and 0.154%, respectively.

[0029] What is not mentioned in the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com