Composite linkage multi-way valve of open center system and hydraulic control method

A multi-way valve and center-opening technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of low power loss, easy failure, high maintenance cost, etc., to reduce fuel consumption and improve overall Efficiency, good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

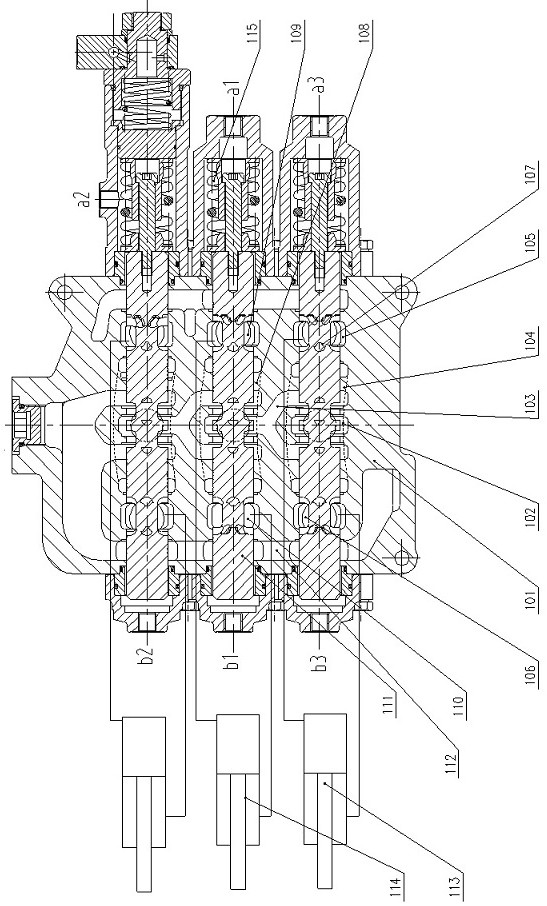

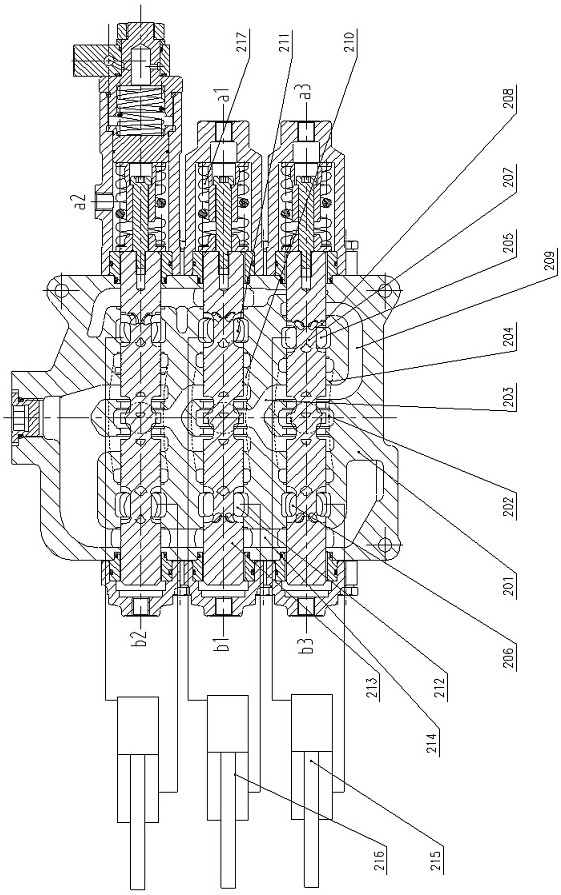

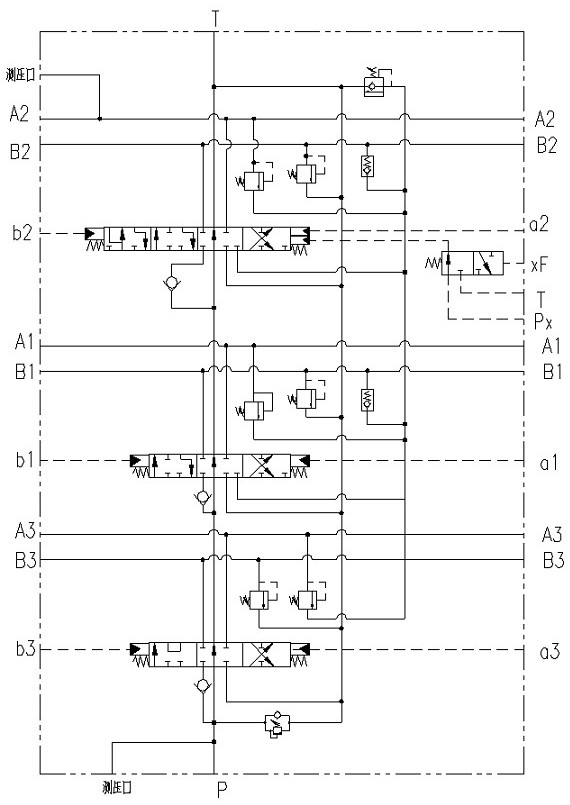

[0014] In order to further explain the specific technical solution of the present invention, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, see figure 2 .

[0015] According to the multi-way valve of the compound linkage hydraulic control method of the open center system implemented in the present invention, it includes a main valve body 201, an oil inlet chamber 202, a neutral oil passage 203, an oil inlet A channel 204, and a working chamber A1 oil port 205 , the working chamber B1 oil port 206, the valve stem A207 is installed in the first joint of the main valve body 201, and is used to control the connection between the oil inlet chamber 202 and the working chamber A1 oil port 205 or the working chamber B1 oil port 206, and the ring groove 208 setting On the outer surface of the valve stem A207, a bridge channel 209 is set in the main valve body 201, which is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com