Device and method for measuring critical chloride ion concentration of reinforcing steel bar depassivation in cement-based material

A cement-based material and chloride ion concentration technology, which is applied in measuring devices, analysis materials, material analysis by electromagnetic means, etc., can solve difficult critical chloride ion concentration, reduce the test accuracy of steel bar depassivation critical chloride ion concentration, and cannot be accurate. Determination of critical chloride ion concentration and other issues to achieve the effect of accelerating transmission and shortening the test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

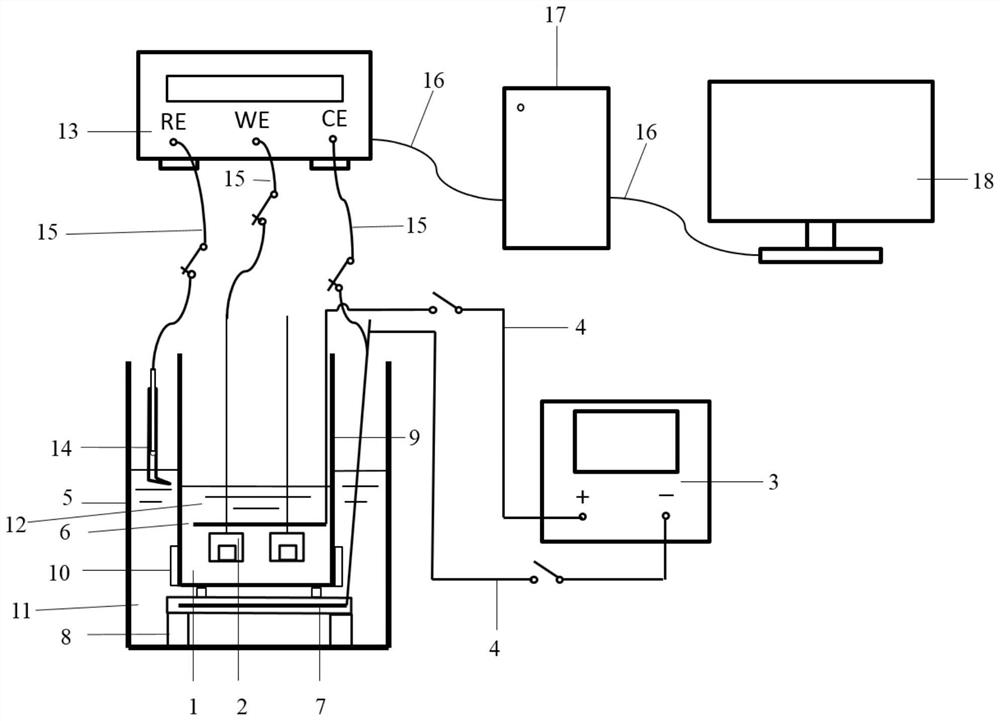

[0027] like figure 1 , The measurement of the cement-based material in the present invention means steel on chloride threshold concentration depassivation, comprising a member to be tested, chloride ion migration and electrochemical testing apparatus of means. Specific configurations and connection relationship of:

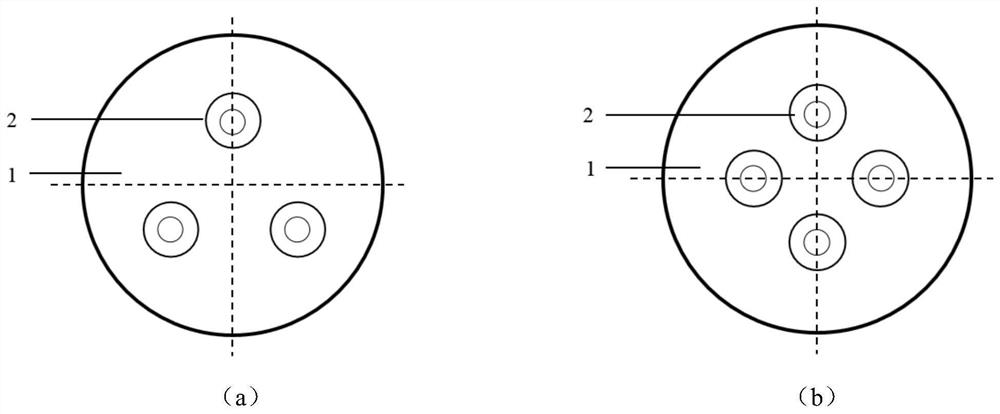

[0028] The test piece 1 to be embedded as a plurality of reinforced cement-based material of the electrode 2 of cylindrical specimens, steel welding electrode end surface 2 of 20mm has a length of copper wire, the lower end surface polished using abrasive paper to a mirror progressively , as tested by the following end faces face the rest surface with reinforced epoxy resin, reinforced bottom surface of the test electrode 2 and the surface of the test piece 1 to be parallel to the electrode 2 and the steel cylinder to be uniformly distributed in the cross section of the test piece, in three and four embedded steel electrodes, for example, such as figure 2 In (a) and f...

Embodiment 2

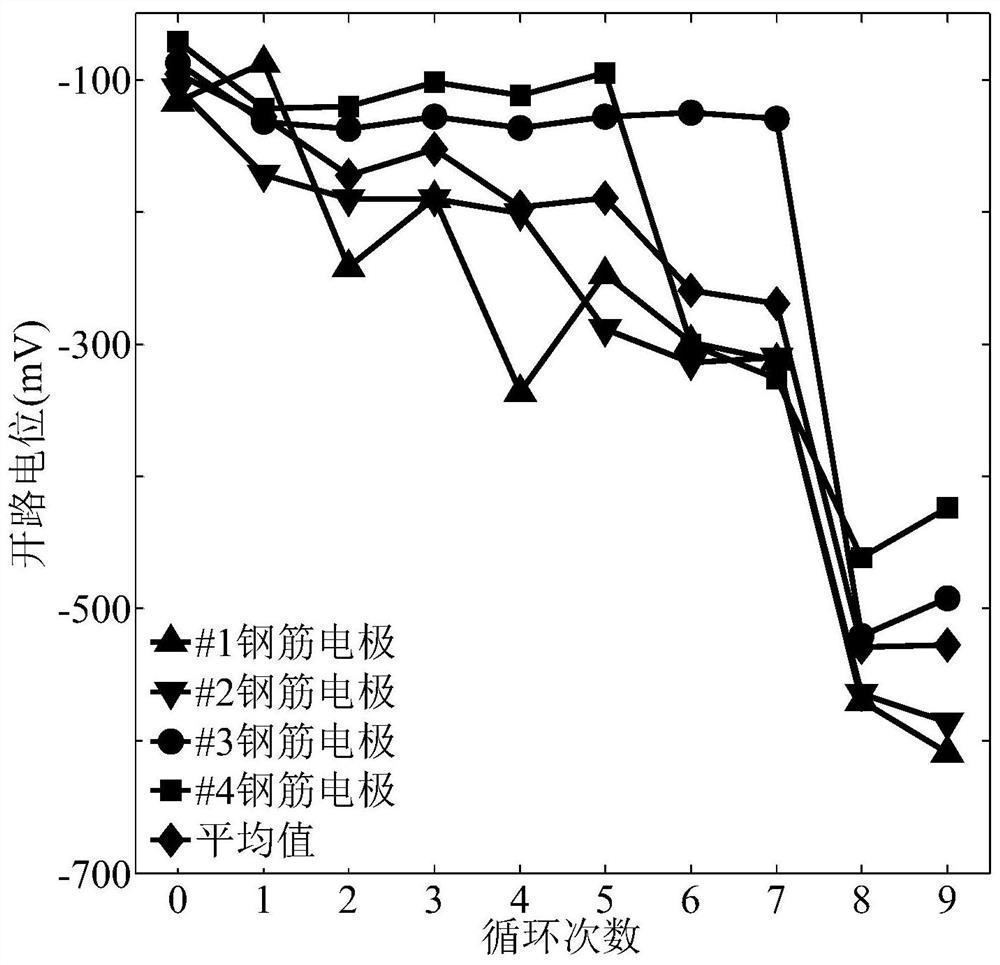

[0033] This example is an example of a method of determining a method of determining a mortal chloride concentration of a reinstallowtuts in a cement-based material according to the present invention, including the following steps:

[0034] (1) Carrying the chloride electromigration cycle test using a chloride ion electromulator

[0035] The cement-based material cylindrical material of the multi-reinforced electrode 2 is poured to be tested 1, and the maintenance room is maintained for 28 days later. The tester 1 is vacuumped before the test, and then secured to the rubber sleeve 9 using the stainless steel throat 10, and the bottom surface of the tester 1 is in the lower end of the rubber sleeve 9, On the support frame 8 in the electrolyte water tank 5, the anode conductive plate 6 is placed on the top surface of the tester 1, and the anode solution 12 is injected into the rubber sleeve 9, and the cathode solution 11 is injected into the electrolyte water tank 11, and the energi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com