High-concentration tritium water treatment device

A water treatment device, high-concentration tritium technology, applied in chemical/physical process, physical/chemical process catalyst, reduction of greenhouse gases, etc., can solve problems such as low tritium removal factor, unfavorable tritium recovery, complex radiation reaction, etc. Increase the tritium removal factor, enhance the tritium removal factor, and reduce the effect of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

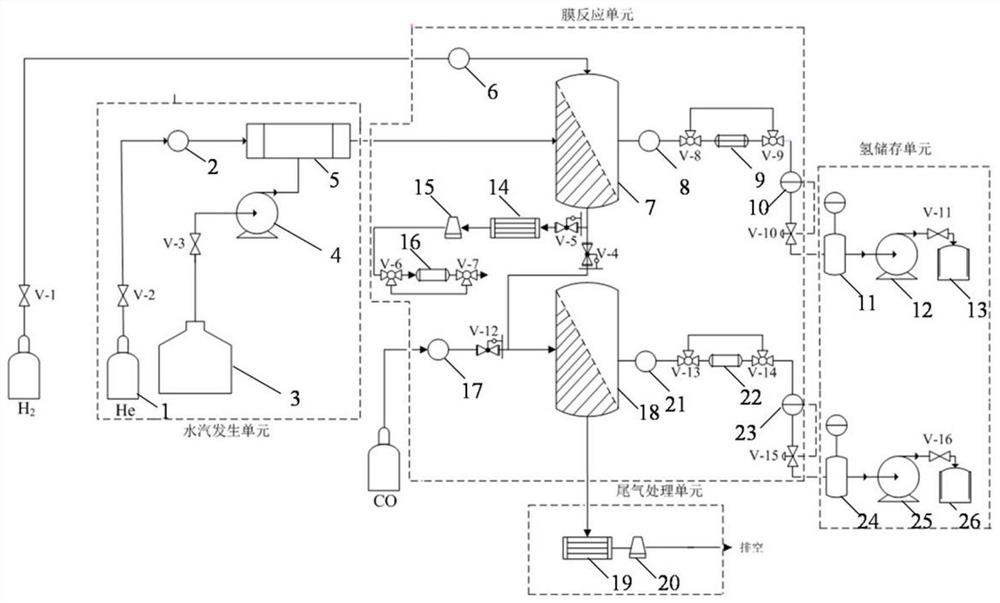

Embodiment 1

[0040] In this example, the high-concentration tritium water treatment device of the present invention is used for tritium water treatment, and the specific two-cascade treatment mode, the first-stage palladium membrane reactor is filled with catalyst Pt / CeO 2 , the second-stage palladium membrane reactor mixed with catalyst Pt / Al 2 o 3 and the adsorbent Li 4 SiO 4 . Set concentration C1 to 10 10 After the Bq / L tritium water is gasified, it is passed into the first-stage palladium membrane reactor at a rate of 10L / h according to the flow rate V1, and the tritium water concentration C2 after the treatment of the first-stage palladium membrane reactor is obtained by measuring the tritium water concentration detection branch. 6.8×10 8 Bq / L, continue to pass the tritium water into the secondary palladium membrane reactor for treatment, and the flow rate V2 of the remaining tritium water after treatment is 0.02L / h. From the above data, it can be calculated that the tritium re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com