Composite material and polymer positive temperature coefficient thermistor made of composite material

A composite material and polymer technology, applied in the field of polymer positive temperature coefficient thermistors, can solve the problems of affecting resistance value, coupling agent precipitation, large amount of graft polymer, etc., to meet the stability and excellent room temperature. Low resistivity, the effect of maintaining low resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

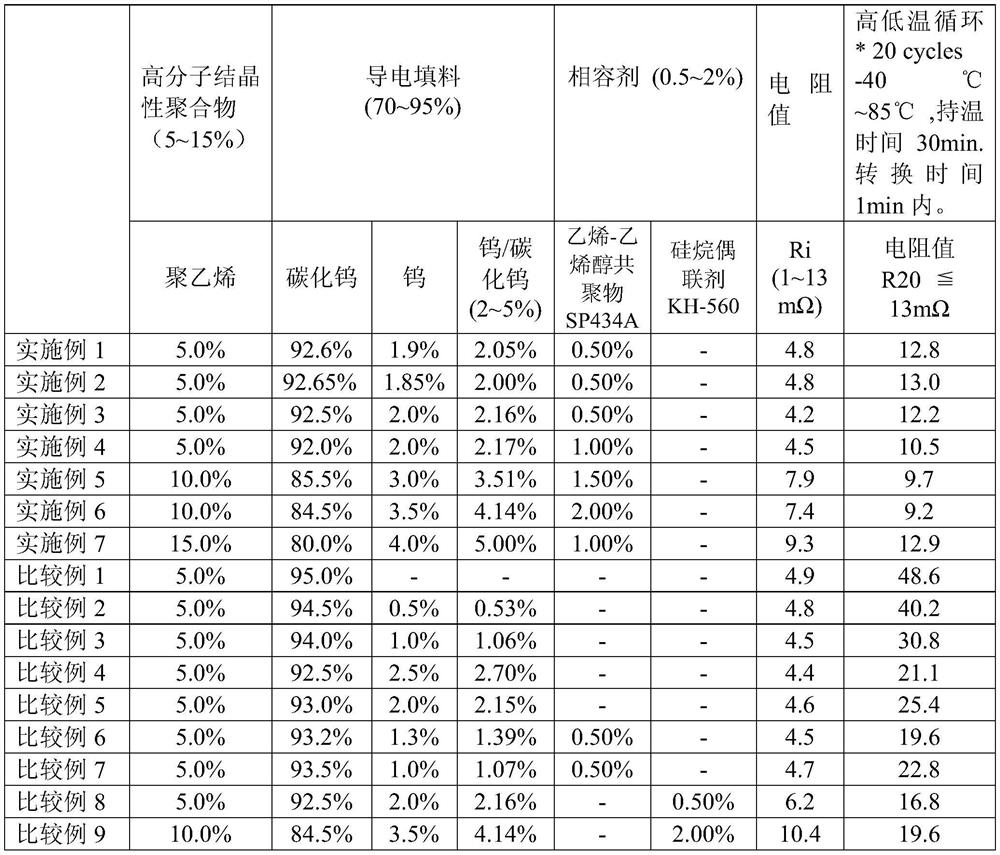

[0031] Comparing the material components and weight percentages of Example 1 and Comparative Example 6, the difference lies in the ratio of metal tungsten to tungsten carbide. In Example 1 with a ratio of metal tungsten to tungsten carbide of 2.05%, compared to Comparative Example 6 with a ratio of metal tungsten to tungsten carbide of 1.39%, the resistance value after multiple high and low temperature cycles decreased by about 35%. In a similar situation, compared to Comparative Example 7 in which the ratio of metal tungsten to tungsten carbide was 2.00% in Example 2, which was 1.07% in metal tungsten to tungsten carbide, the resistance value after multiple high and low temperature cycles decreased by about 43%.

Embodiment 3

[0032] Compared with the material components and weight percentages of Example 3 and Comparative Example 8, the difference lies in the selection of the compatibilizer. Compared with the compatibilizer in Example 3, which uses ethylene-vinyl alcohol copolymer, the compatibilizer uses a silane coupling agent. In Comparative Example 8, the resistance value after multiple high and low temperature cycles was reduced by about 27%. In a similar situation, the compatibilizer was selected from ethylene-vinyl alcohol copolymer compared with Example 6 in which the compatibilizer was selected from silane coupling agent. In Comparative Example 9, the resistance value after multiple cycles of high and low temperature decreased by about 53%.

Embodiment 7

[0033] Comparing the material composition and weight percentage of Example 7 and Comparative Example 11, the weight percentage of polyethylene is the same, and the ratio of metal tungsten to tungsten carbide is similar. The difference lies in whether ethylene-vinyl alcohol copolymer is used as a compatibilizer. Compared with Comparative Example 11 in which ethylene-vinyl alcohol copolymer was used as a compatibilizer, the resistance value after multiple high and low temperature cycles was reduced by about 30%. In a similar situation, compared with Comparative Example 5 in which ethylene-vinyl alcohol copolymer was used as a compatibilizer, the resistance value after multiple high and low temperature cycles was reduced About 59%.

[0034] The effect of the proportion of ethylene in the compatibilizer ethylene-vinyl alcohol copolymer of the composite material layer 102 of the present invention on the resistance value after multiple high and low temperature cycles is shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com