Heating device and bonding device

A heating device and heating element technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low heating efficiency, achieve weight reduction, good thermal conductivity, and improve heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

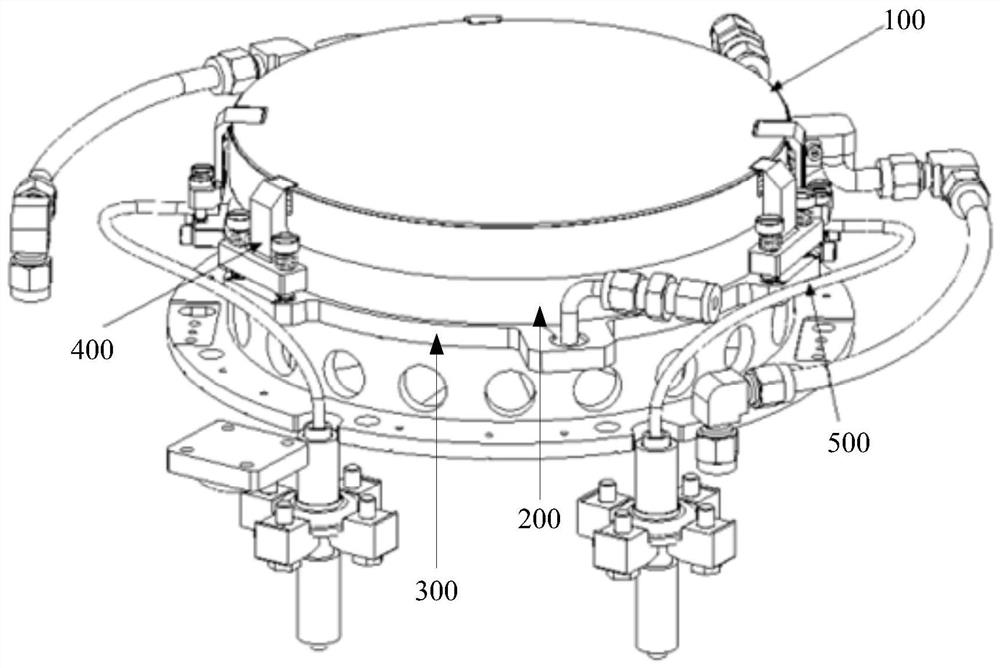

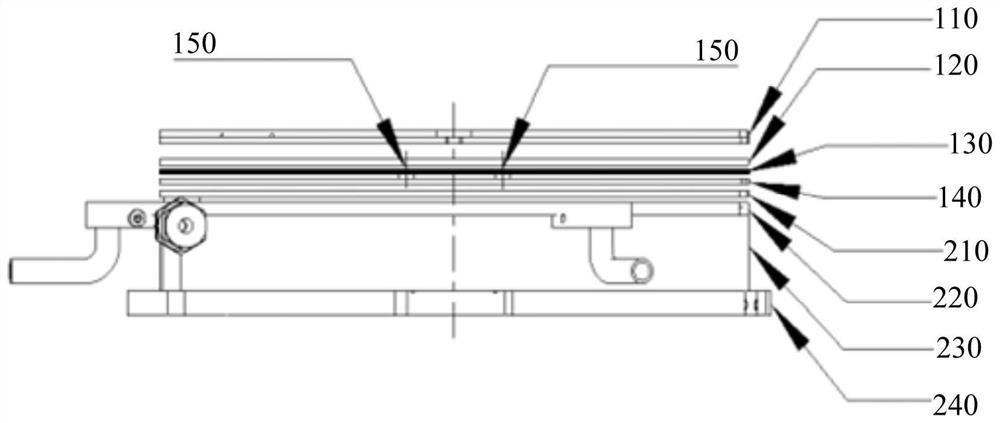

[0068] This embodiment provides a heating device. refer to figure 1 and figure 2 , figure 1 is a schematic structural view of the heating device in Embodiment 1 of the present invention, figure 2 It is a schematic cross-sectional view of the heating device in Embodiment 1 of the present invention, and the heating device includes a heating unit 100 , a cooling unit 200 , a base 300 , a fixing unit 400 and a wire unit 500 .

[0069] refer to figure 2 , the heating unit 100 includes a surface layer 110 , an upper supporting layer 120 , a heating element 130 , a lower supporting layer 140 and at least one positioning pin 150 stacked in sequence.

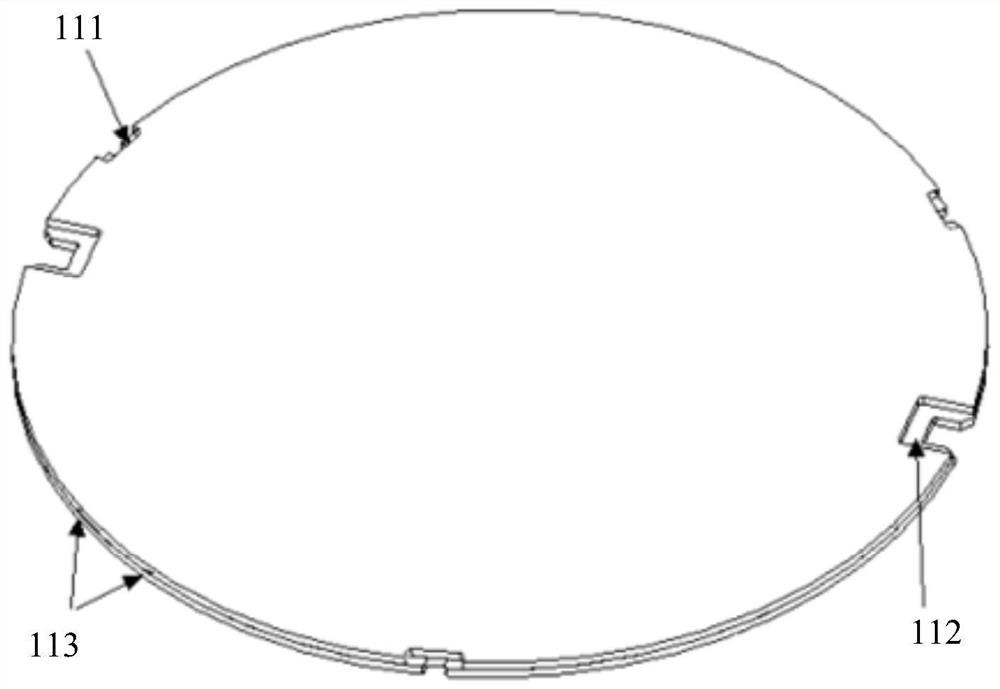

[0070] refer to image 3 , image 3 It is a schematic structural diagram of the surface layer 110 in Embodiment 1 of the present invention. The surface layer 110 is located on the uppermost layer and can be in direct contact with the workpiece to be heated, so as to make the workpiece to be heated uniformly heated. The surface ...

Embodiment 2

[0111] This embodiment provides a heating device. The difference between the heating device in this embodiment and the heating device in Embodiment 1 is that the heating device in this embodiment includes a heating unit 100, a cooling unit 200, a base 300, a wire unit 500 and a fixing unit 400, but the The cooling unit 200 does not include the cooling member 220 . The lower supporting layer 140 in the heating unit 100 is arranged on the heat conduction layer 210 in the cooling unit 200, the heat conduction layer 210 is arranged on the heat insulation layer 230, and the heat insulation layer 230 is arranged on the bottom layer 240 superior. The fixing unit 400 is used to fix the heating unit 100 and the cooling unit 200 on the base 300 .

[0112] In other embodiments, the heating device does not include the cooling unit 200, the lower support layer 140 in the heating unit 100 is arranged on the base 300, and the fixing unit 400 is used to fix the heating unit 100 On the base...

Embodiment 3

[0114] This embodiment provides a heating device. The difference between the heating device in this embodiment and the heating device in Embodiment 1 is that the heating device in this embodiment further includes a pressing plate, and the pressing plate is arranged on the side of the surface layer 110 away from the upper supporting layer 120 , the press plate can directly contact the surface of the wafer and apply pressure to the wafer for bonding.

[0115] The material of the pressing plate is preferably silicon carbide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com