Semiconductor silicon wafer patch based on thermal winding technology

A semiconductor and chip technology, which is applied in the field of semiconductor silicon chip patch based on heat entanglement technology, can solve the problem of semiconductor silicon wafer and chip bulge, the occurrence of bubbles between chip and semiconductor silicon chip, and the problem of chip and semiconductor silicon chip. Insufficient bonding and other problems to achieve the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

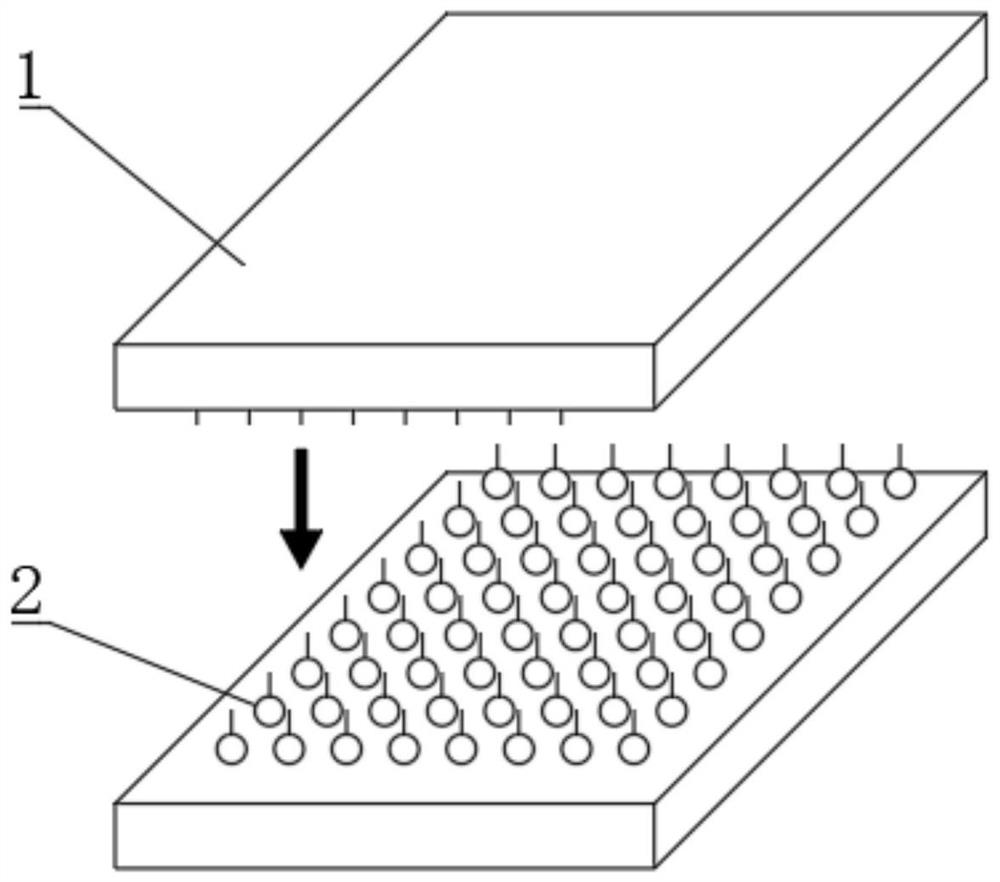

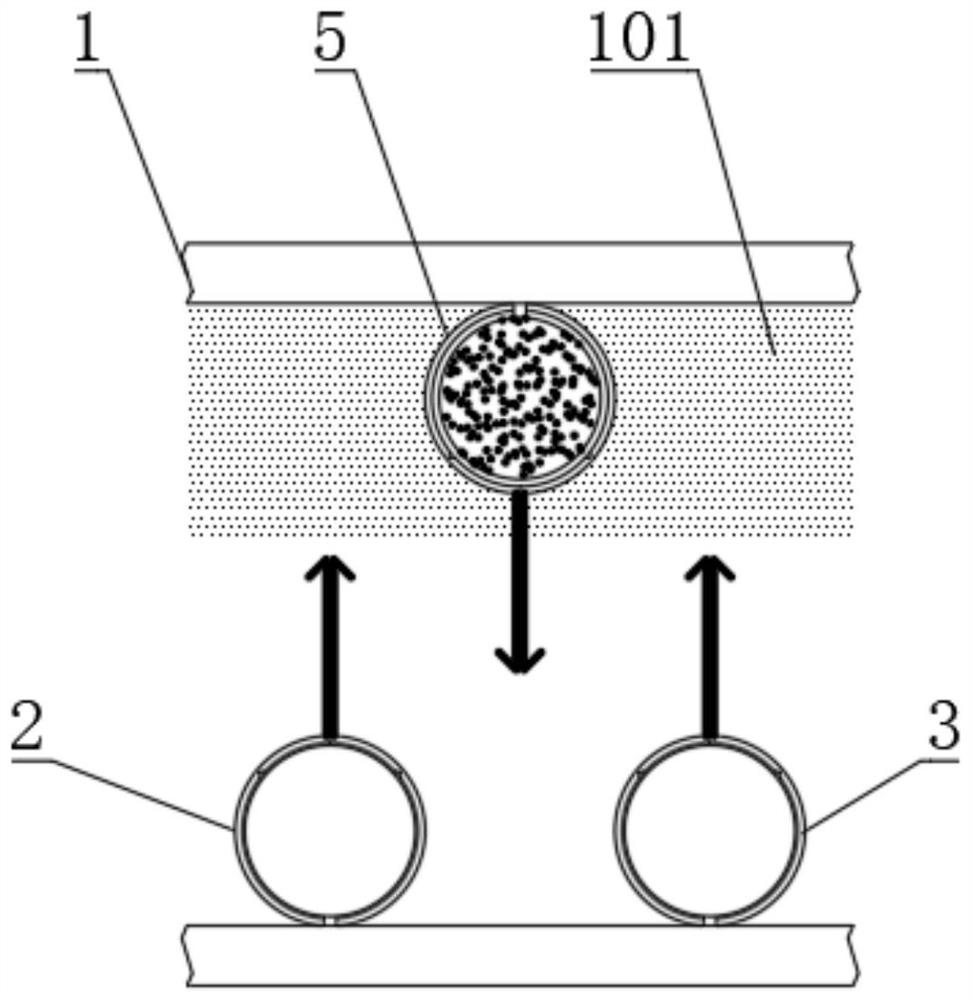

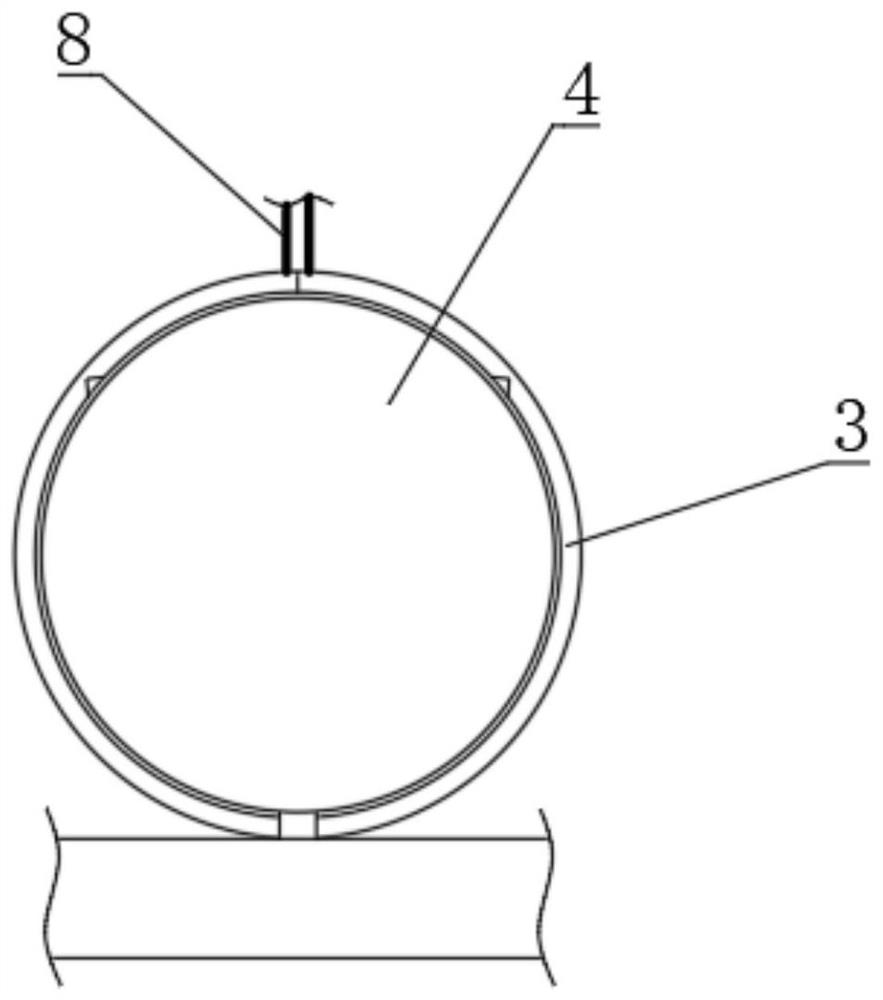

[0043] see Figure 1-8 , a semiconductor silicon chip patch based on thermal winding technology, including a patch body 1 and a plurality of evenly distributed scattered hook balls 2, the scattered hook balls 2 are usually evenly distributed and bonded to the semiconductor silicon wafer during actual use. On the sheet surface, the scattered hook balls 2 include a first outer encapsulation layer 3, the inner bottom of the first outer encapsulation layer 3 is fixedly connected with the main magnetic ball 4, and the bottom end of the patch main body 1 is fixedly connected with the second outer encapsulation layer 5, the second The inner top of the outer encapsulation layer 5 is fixedly connected with a reaction mill ball 6, the first outer encapsulation layer 3 and the second outer encapsulation layer 5 are composed of a plurality of evenly distributed fan-shaped capsules 7, and the upper end of the first outer encapsulation layer 3 is fixedly connected There are a plurality of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com