Preparation method of starch-based emulsion filled gel fat mimetic

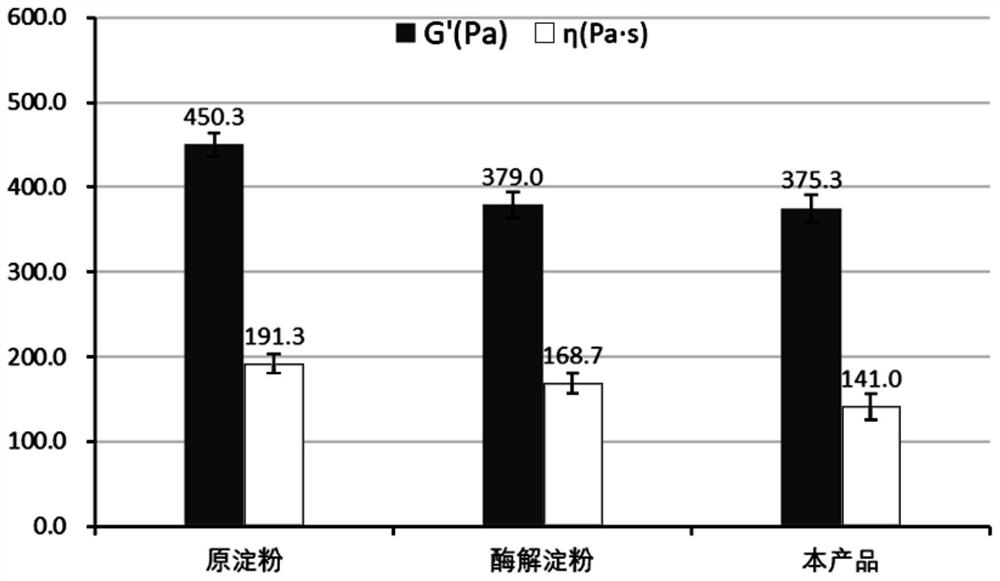

A fat simulant and starch-based technology, which is applied in the field of food processing, can solve the problems of poor fat simulation effect, achieve the effects of lower viscosity, less energy consumption, and reduce aging phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a starch-based emulsion-filled gel fat simulant.

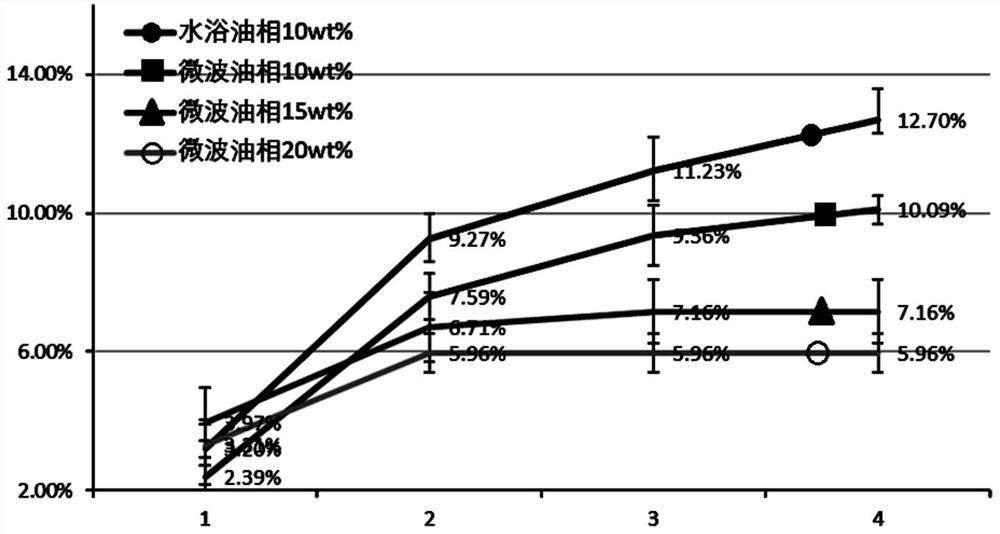

[0036] (1) Emulsification: After mixing the oil phase, water and emulsifier, homogenize twice through a homogenizer at 30Mpa to obtain a stable O / W emulsion.

[0037] (2) Rice starch is used as raw material, add water to make starch milk, put it into a vacuum packaging bag, shake it well, put it into an ultra-high pressure treatment device, set the pressure at 400MPa, and carry out ultra-high pressure treatment for 10 minutes, and the temperature in the high-pressure chamber is maintained at 25°C. Add 0.1% (0.1g enzyme / per 100g starch) of medium temperature α-amylase with an enzyme activity of 800FAU / g to the treated starch milk, control pH 6.0-6.5, keep it warm at 50°C for 5 minutes, add NaOH to inactivate the enzyme, and put Dry in an oven at 50°C and grind through a 100-mesh sieve.

[0038] (3) The starch in step (2), water and the emulsion obtained in step (1) are shaken and mixed evenly, an...

Embodiment 2

[0043] A method for preparing a starch-based emulsion-filled gel fat simulant.

[0044] (1) Emulsification: After mixing the oil phase, water and emulsifier, homogenize twice through a homogenizer at 30Mpa to obtain a stable O / W emulsion.

[0045] (2) Rice starch is used as raw material, add water to make starch milk, put it into a vacuum packaging bag, shake it well, put it into an ultra-high pressure treatment device, set the pressure at 200MPa, and carry out ultra-high pressure treatment for 20 minutes. The temperature in the high-pressure chamber is maintained at 25°C. Add 0.1% (0.1g enzyme / per 100g starch) to the treated starch milk with an enzyme activity of 800FAU / g medium-temperature α-amylase, control the pH to 6.0-6.5, keep it at 50°C for 20 minutes, add NaOH to inactivate the enzyme and put Dry in an oven at 50°C and grind through a 100-mesh sieve.

[0046] (3) The starch in step (2), water and the emulsion obtained in step (1) are shaken and mixed evenly, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com