Corrugated board printing production line

A technology of corrugated board and production line, which is applied in the field of corrugated board manufacturing, can solve the problems such as the inability to continuously automate the cleaning and packing of corrugated boards, and achieve the effects of reducing warped flash, simple structure, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is further described in detail through specific implementation methods:

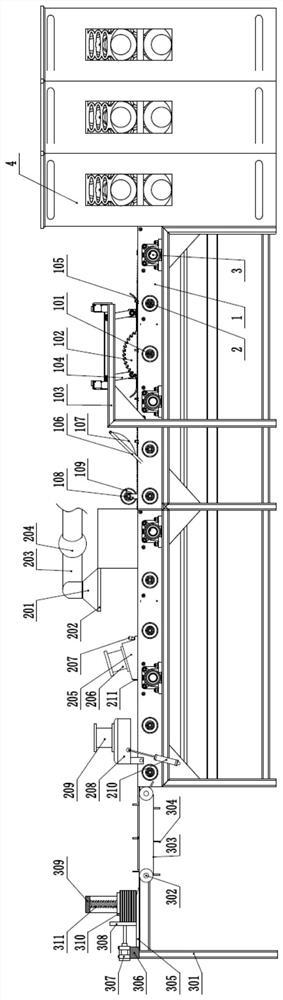

[0035]The reference signs in the accompanying drawings of the specification include: machine body 1, conveying roller 2, first drive motor 3, printing machine 4, cutting roller 101, cutting knife 102, support plate 103, connecting rod 104, extrusion sheet 105, adjusting rod 106, rubber sheet 107, support sheet 108, leveling roller 109, exhaust tube 201, baffle 202, exhaust pipe 203, negative pressure fan 204, support shell 205, first dust removal fan 206, cover plate 207, support frame 208 , the second dust removal fan 209, the first telescopic cylinder 210, the cleaning brush 211, the workbench 301, the drive roller 302, the transmission belt 303, the baffle plate 304, the packing platform 305, the spacer 306, the second telescopic cylinder 307, the positioning plate 308 , Carrying frame 309, squeeze plate 310, compression spring 311.

[0036] The embodiment is basically as attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com