Preparation method of toughened building ceramic product and ceramic product

A technology for architectural ceramics and products, applied in the field of ceramic materials, to achieve high practical value and application prospects, to speed up the construction of ecological civilization, and to achieve simple and easy-to-control effects in preparation, application and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

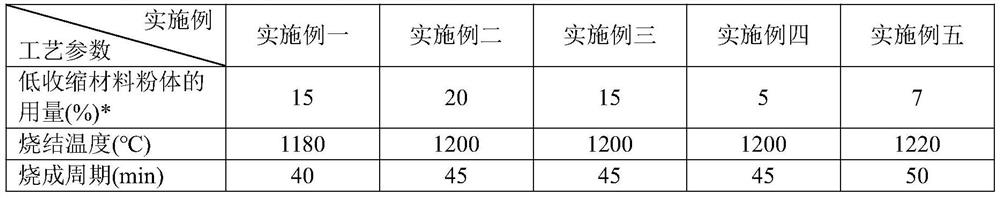

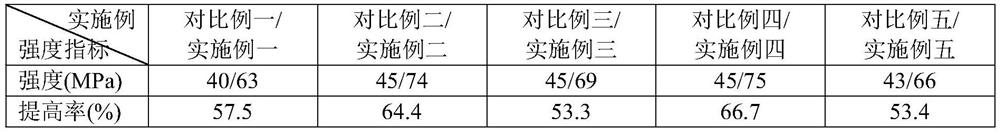

[0022] An embodiment of the present invention is a method for preparing a toughened architectural ceramic product, which is prepared from architectural ceramic green body powder and low-shrinkage material powder. The building ceramic body used adopts the formula of building ceramic porcelain body, and its raw materials are composed of 30 parts of kaolin, 20 parts of quartz, 35 parts of feldspar, 5 parts of talc and 10 parts of medium temperature sand in parts by weight. The steps of the above-mentioned preparation method are as follows:

[0023] (1) Preparation of low shrinkage material powder

[0024] The low-shrinkage material is one of the following materials or a combination thereof, or a combination with porcelain powder: SiO 2 Main minerals or rocks, wollastonite, diopside, cordierite, tremolite, pyrophyllite, andalusite, sillimanite; porcelain powder is the powder after the above-mentioned building ceramic body is sintered into porcelain; the above-mentioned After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com