Foaming agent composition, its preparation method and application

A composition and foaming agent technology, applied in the field of foam materials and polyurethane foam materials, can solve the problems of shrinkage of foam materials, high viscosity of combined polyether, and decrease of adhesive force of foam materials, and achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

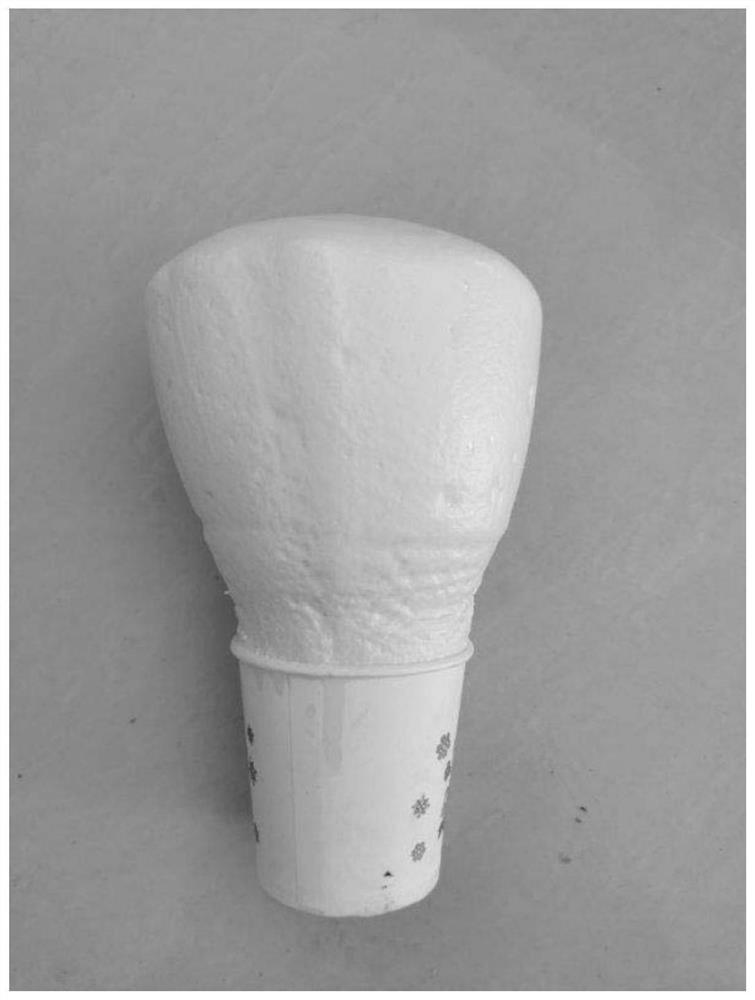

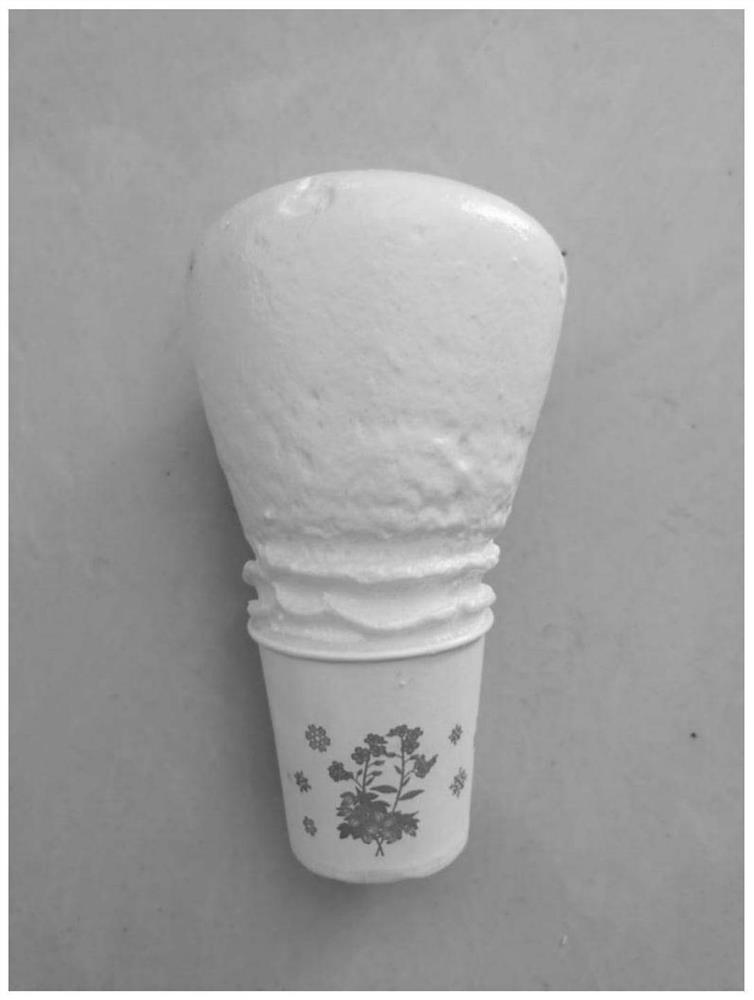

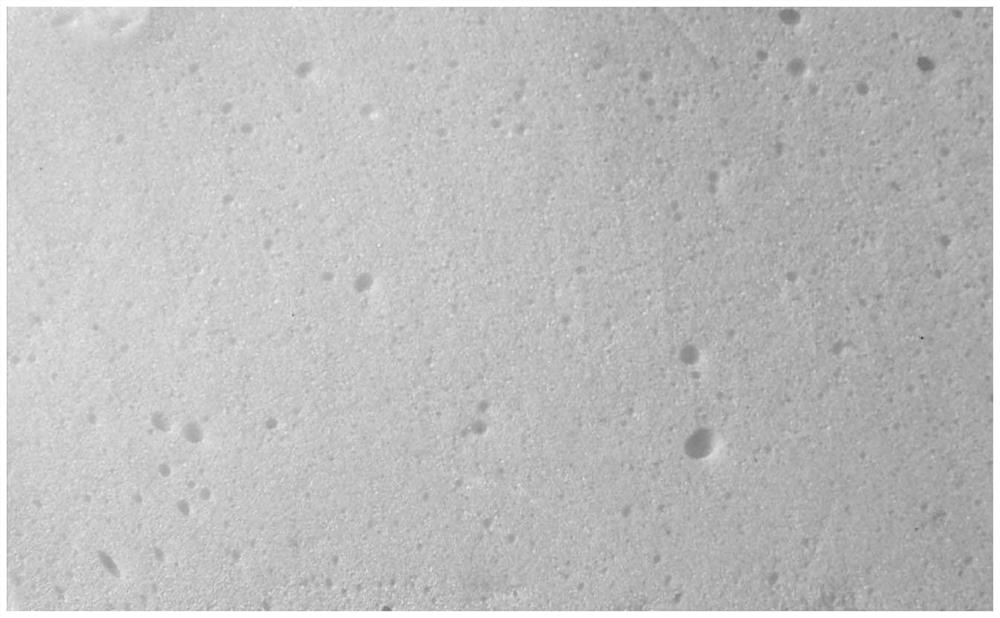

Image

Examples

Embodiment 1-9 and comparative example 1

[0215] The foaming agent compositions A in Examples 1-9 and the foaming agent of Comparative Example 1 were prepared according to the ratios shown in Table 1. In Table 1, the units of numerical values representing the ratios of each raw material are parts by weight. Among the raw materials used in Examples 1-9, polyether 1020D is a diol polyether, and polyether 307, polyether 310 and polyether 305 are optional triol polyethers, which are selected in Examples 1-7. White granulated sugar was added, and sorbitol was selectively added in Examples 8-9. Comparative Example 1 is a foaming agent without adding white sugar or sorbitol.

Embodiment 1

[0217] Weigh 120 grams of pure water, pour it into a three-necked flask, heat up, stir to 50 degrees, add 60 grams of white sugar, stir until all the white sugar is dissolved and become transparent, then add 320 grams of 1020D polyether, 120 grams of 307 polyether , 120 grams of plasticizer propylene carbonate, continue to stir for 20 minutes, to obtain uniform and transparent liquid, stop stirring, and measure to obtain 740 grams of chemical foaming agent, namely foaming agent composition A of the present invention.

[0218] The foaming agent compositions A in Examples 2-9 and the foaming agent composition of Comparative Example 1 were prepared according to the preparation method of Example 1.

[0219] Table 1

[0220]

Embodiment 10-17 and comparative example 2

[0222] The foaming agent composition A in Examples 10-17 and the foaming agent of Comparative Example 2 were prepared according to the ratios shown in Table 2. In Table 2, the unit of the numerical value representing the ratio of each raw material is parts by weight. Compared with the raw materials used in Examples 1-9, the raw materials used in Examples 10-17 and Comparative Example 2 were selected to add polyether polyol, that is, polyether 8310. In Examples 10-13, white granulated sugar was selectively added, and in Examples 14-17, sorbitol was selectively added. Comparative Example 2 is a foaming agent without adding white sugar or sorbitol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com