Phase change energy storage strengthening device with built-in ultrasonic generator

A phase-change energy storage and strengthening device technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc. Involving heat and mass transfer enhancement and other issues, to achieve good temperature uniformity and temperature control capabilities, eliminate conduction losses, and improve the effect of energy storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical scheme of the present invention will be clearly and completely described below in conjunction with the accompanying drawings, and the described embodiments are part of the embodiments of the present invention, rather than all embodiments; based on the embodiments of the present invention, those of ordinary skill in the art can All other embodiments obtained under the premise of no creative work belong to the protection scope of the present invention.

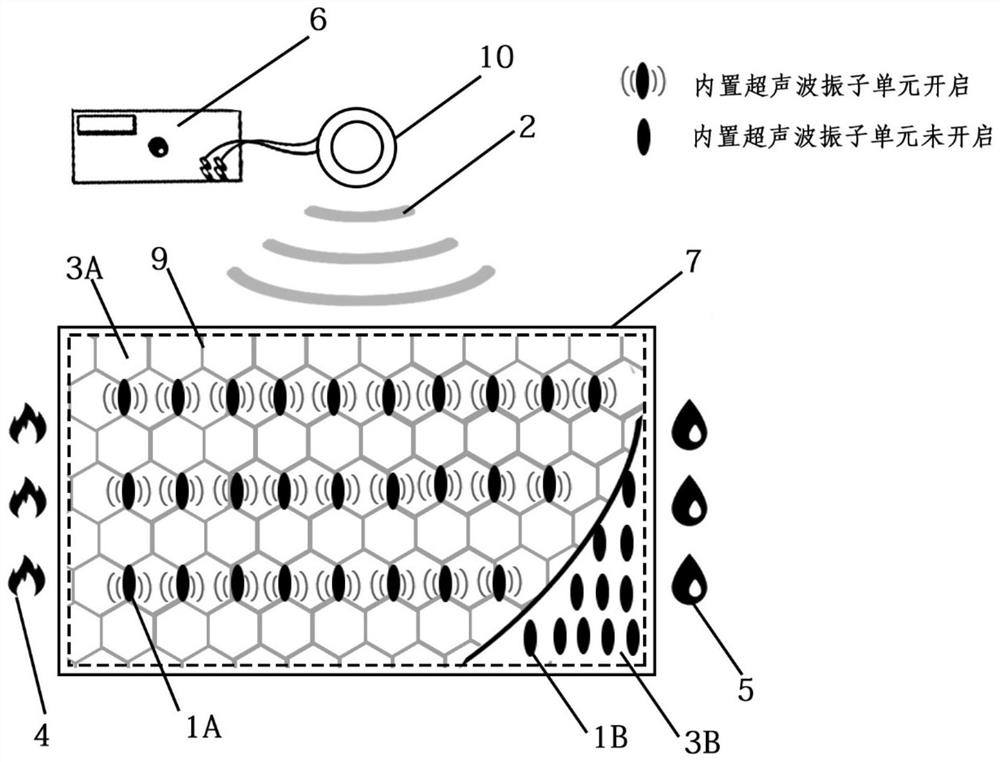

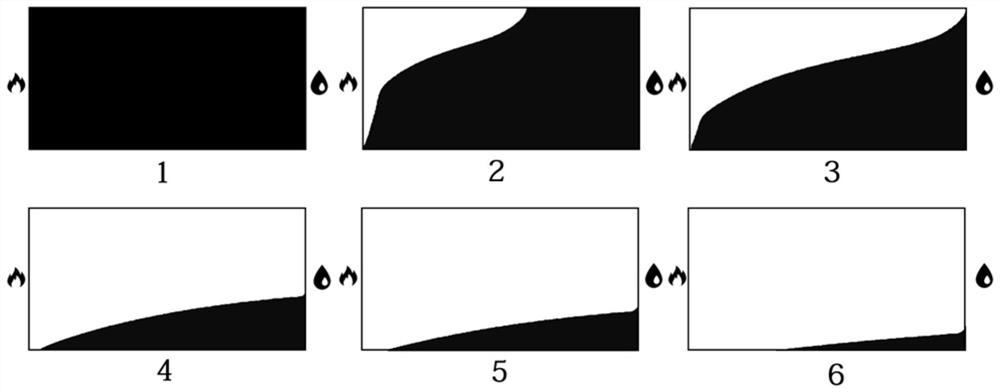

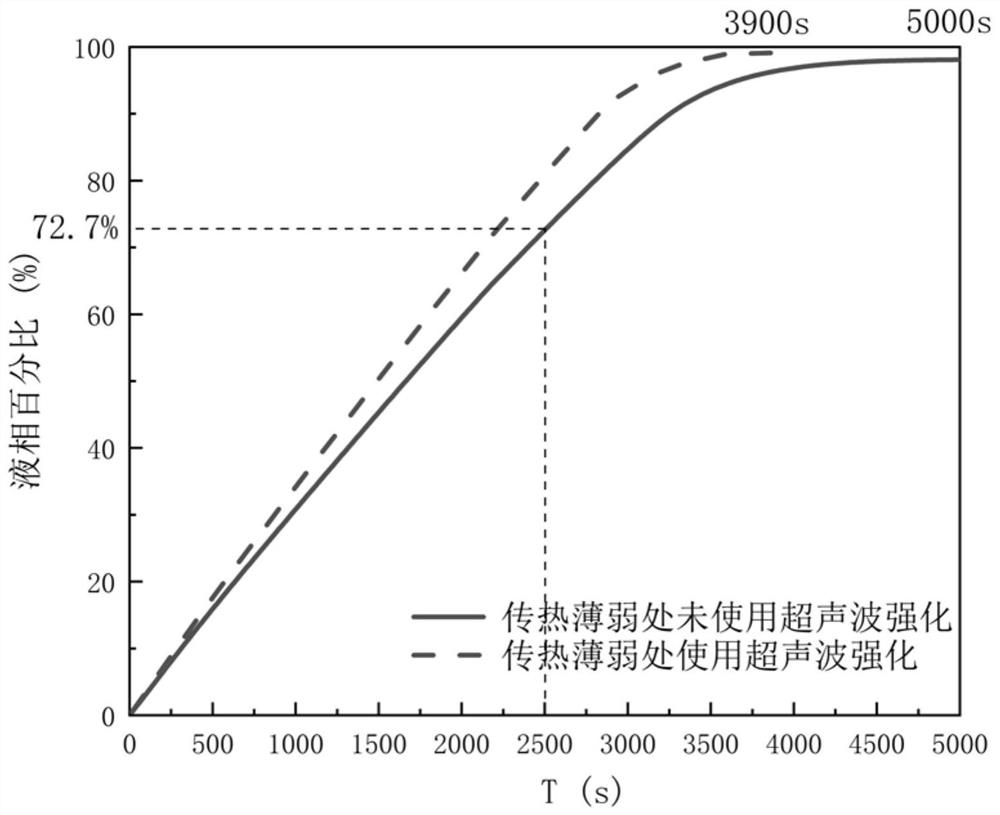

[0035] In this paper, a qualitative numerical simulation is carried out for the phenomenon that there is a hard-to-melt solid phase region in the melting of phase change materials, taking a three-dimensional cubic heat storage unit of 60mm*120mm*100mm as an example. Simulation results with figure 2 , image 3 exhibit. figure 2 It is a schematic diagram of the melting process of the phase change material without ultrasonic waves in the hard-to-melt solid phase region of the energy storage unit, image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com