Method for detecting lip sticking force of cigarette tipping paper

A technology of cigarette tipping paper and detection method, which is applied in the field of analysis and detection, can solve problems such as anti-adhesive lip not mentioned, and achieve the effects of saving detection cost, simple operation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

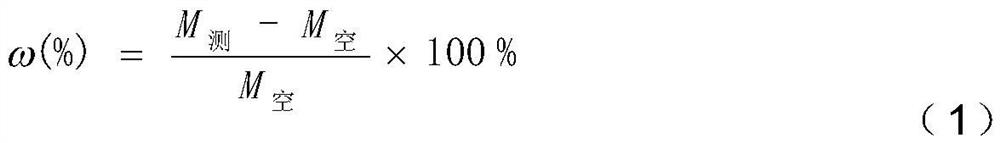

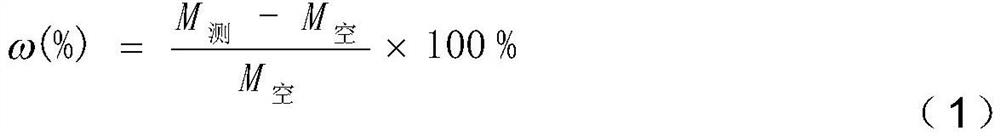

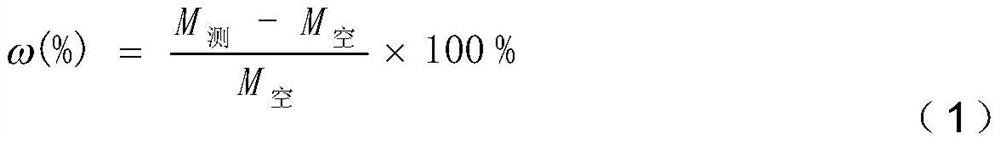

Image

Examples

Embodiment 1

[0038] A method for detecting the sticking force of cigarette tipping paper, comprising the steps of:

[0039] Step (1), cutting the cigarette tipping paper;

[0040] Step (2), weighing the cut test sample;

[0041] Step (3), place the cut test sample flat on the coating platform covered with absorbent paper, with the printing side facing up, accurately pipette a certain amount of artificial saliva, and evenly apply it on the printing surface of the tipping paper, and the scraping is over Start counting at 10:00 pm, and let it stand for a period of time;

[0042] Step (4), when the specified time of standing is reached, place a piece of absorbent paper on the surface of the test sample, then immediately press a certain weight on the absorbent paper and time it, and let it stand for a period of time;

[0043] Step (5), when the specified time is reached, the test sample penetrated by the artificial saliva is weighed;

[0044] Step (6), after the artificial saliva penetrates ...

Embodiment 2

[0052] A method for detecting the sticking force of cigarette tipping paper, comprising the steps of:

[0053] Step (1), cutting the cigarette tipping paper;

[0054] Step (2), weighing the cut test sample;

[0055] Step (3), place the cut test sample flat on the coating platform covered with absorbent paper, with the printing side facing up, accurately pipette a certain amount of artificial saliva, and evenly apply it on the printing surface of the tipping paper, and the scraping is over Start counting at 10:00 pm, and let it stand for a period of time;

[0056] Step (4), when the specified time of standing is reached, place a piece of absorbent paper on the surface of the test sample, then immediately press a certain weight on the absorbent paper and time it, and let it stand for a period of time;

[0057] Step (5), when the specified time is reached, the test sample penetrated by the artificial saliva is weighed;

[0058] Step (6), after the artificial saliva penetrates ...

Embodiment 3

[0075] A method for detecting the sticking force of cigarette tipping paper, comprising the steps of:

[0076] Step (1), cutting the cigarette tipping paper;

[0077] Step (2), weighing the cut test sample;

[0078] Step (3), place the cut test sample flat on the coating platform covered with absorbent paper, with the printing side facing up, accurately pipette a certain amount of artificial saliva, and evenly apply it on the printing surface of the tipping paper, and the scraping is over Start counting at 10:00 pm, and let it stand for a period of time;

[0079] Step (4), when the specified time of standing is reached, place a piece of absorbent paper on the surface of the test sample, then immediately press a certain weight on the absorbent paper and time it, and let it stand for a period of time;

[0080] Step (5), when the specified time is reached, the test sample penetrated by the artificial saliva is weighed;

[0081] Step (6), after the artificial saliva penetrates ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com