Method for remediating industrial wastewater

A waste liquid and waste technology, applied in the field of industrial wastewater holding tanks, can solve the problems of harsh biological activity, hindering widespread use, and frequent failure of mechanical parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] specific implementation plan

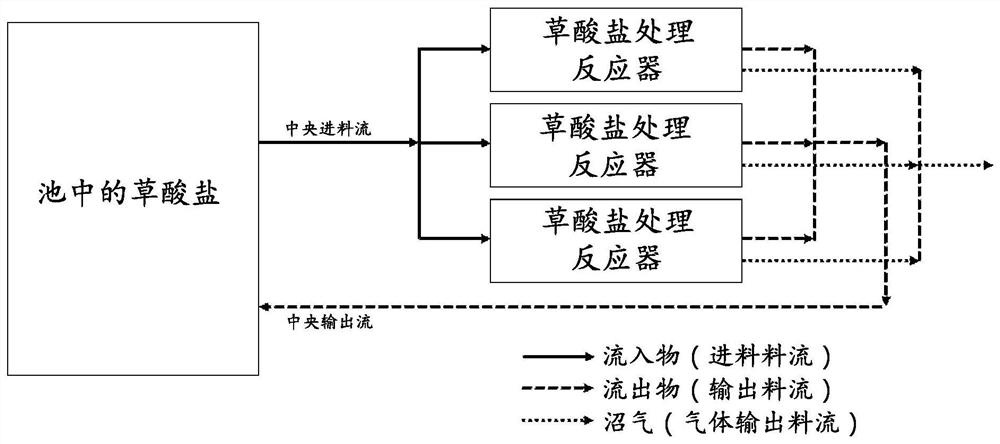

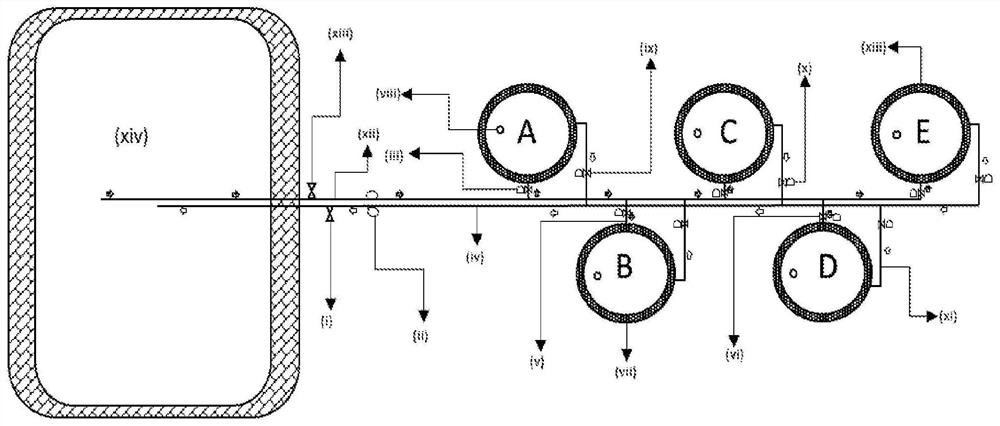

[0040] The main purpose of the present invention is to remediate stored effluents under anaerobic biodegradation conditions (which do not suffer from the aforementioned disadvantages of aerobic digestion, or the environmental costs of thermal destruction methods), although stored effluents have (at least initially ) bulk properties that are incompatible with anaerobic biodegradation. In particular embodiments, the present invention facilitates the controlled introduction of oxalate-consuming seed bacteria into ponds and systematically lowers the pH of the ponds through the effluents of multiple individually maintained bioreactors to facilitate the The level at which continuous biological oxalate degradation takes place in the pond can be advantageously used to ensure the treatment of oxalate-containing wastewater left in the storage pond.

[0041] Accordingly, the present invention provides a method for reconditioning stored waste liquids...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com