Preparation method of montmorillonite film capable of stably existing in solution

A technology of montmorillonite and film, which is applied in the field of preparation of montmorillonite film, can solve the problems of poor high temperature resistance of organic matter, complex reassembly process, poor stability of montmorillonite film material, etc., and achieve dispersibility and hydration expansion The effect of reduced resistance, improved stability, and simple and efficient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of preparation method of the montmorillonite thin film that can exist stably in solution, concrete steps are as follows:

[0022] 1) Disperse 1.5g lithium-based montmorillonite sample in pure water to prepare 30mL of 5wt% lithium-based montmorillonite slurry, prepare montmorillonite film A1 by vacuum filtration, and separate montmorillonite film A1 from the filter membrane ;

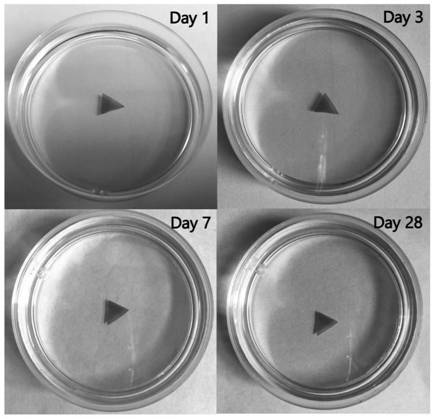

[0023] 2) Montmorillonite film A1 was dried at 60°C for 15 hours, then annealed at 100°C for 6 hours, and then annealed at 250°C for 24 hours to obtain montmorillonite film sample A2, which is stable in water There are more than 28d.

Embodiment 2

[0025] A kind of preparation method of the montmorillonite thin film that can exist stably in solution, concrete steps are as follows:

[0026] 1) Disperse 1.5g lithium-based montmorillonite sample in pure water to prepare 30mL of 5wt% lithium-based montmorillonite slurry with a strength of 267W / cm 2 Under the condition of ultrasonic stripping for 10 minutes, the montmorillonite film A1 was prepared by vacuum filtration, and the montmorillonite film A1 was separated from the filter membrane;

[0027] 2) Montmorillonite film A1 was dried at 60°C for 15 hours, then annealed at 100°C for 6 hours, and then annealed at 230°C for 24 hours to obtain montmorillonite film sample A2, which is stable in water There are more than 28d.

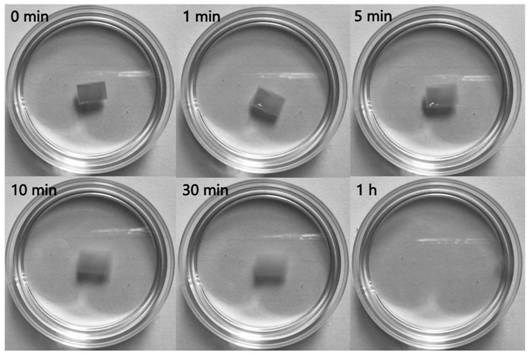

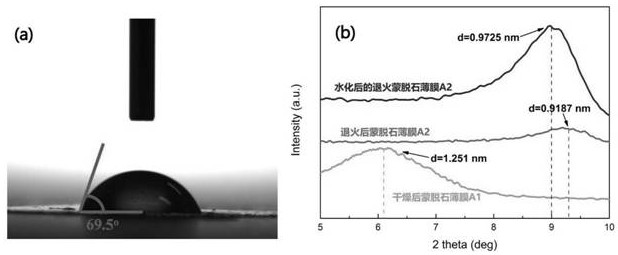

[0028] Such as figure 1 As shown, the stability of montmorillonite film A1 in water is poor, and it will be completely disintegrated after soaking for 1 hour; after two stages of low-temperature annealing treatment, the stability of montmorillonite film ...

Embodiment 3

[0031] A kind of preparation method of the montmorillonite thin film that can exist stably in solution, concrete steps are as follows:

[0032] 1) Disperse 3g of Na-montmorillonite sample in pure water to prepare 30mL of 10wt% Na-montmorillonite slurry with a strength of 267W / cm 2 Under the condition of ultrasonic stripping for 10 minutes, the montmorillonite film A1 was prepared by vacuum filtration, and the montmorillonite film A1 was separated from the filter membrane;

[0033] 2) Dry the montmorillonite film A1 at 60°C for 15 hours, then anneal at a low temperature at 100°C for 6 hours, and then anneal at a low temperature at 230°C for 24 hours to obtain a montmorillonite film sample A2, which can be prepared in KCl salt It is stable in solution (1M) for more than 28d.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap