Laser-induced free-form surface periodic nanostructure pattern and coloring method

A nanostructure and laser-induced technology, applied in nanotechnology, microstructure technology, microstructure devices, etc., can solve the problems of response speed, degree of automation and precision that cannot be satisfied at the same time, inconsistent laser incident direction, and changes in processing parameters, etc., to achieve Clear coloring effect, ensure high efficiency and high precision, and ensure the effect required by processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

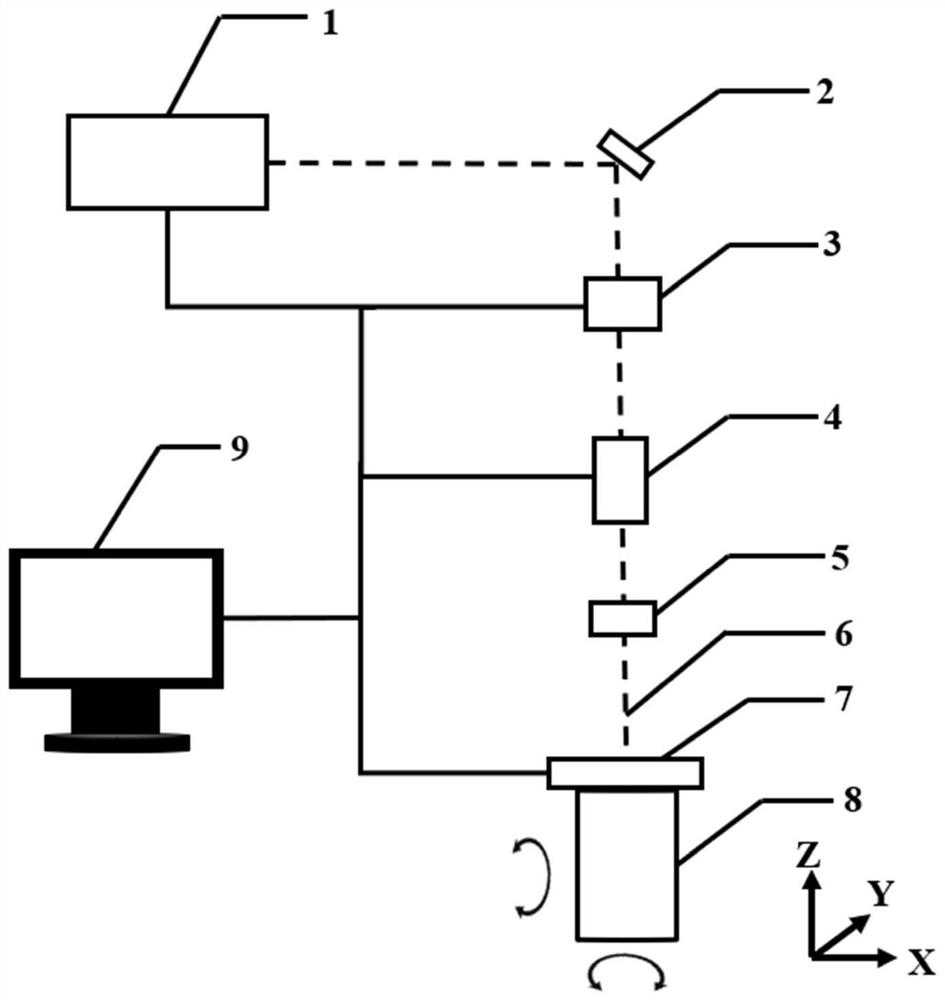

[0047] 1) Build a laser synchronous polarization control processing system

[0048] See attached figure 1 , build a laser synchronous polarization control processing system, so that the laser beam 6 converges on the sample stage 7 through the optical path of the lens system 2, the half-wave plate and the liquid crystal polarization rotator 3, the dynamic beam expander 4 and the lens 5. After converging, the spot diameter is 24μm, and the energy density is 7.52J / cm 2 ;

[0049] 2) Set processing conditions

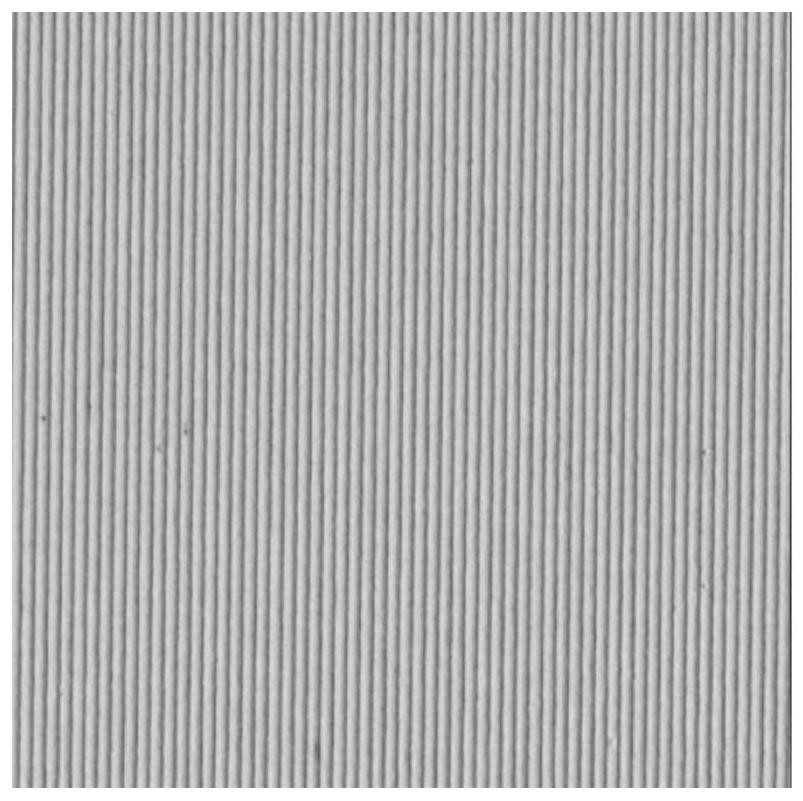

[0050] Control the energy flux density of the laser to 7.52J / cm 2 , the scanning speed is 7mm / s, and the spot diameter of the laser beam converging on the sample surface is 24μm, which ensures that the formed stripes are arranged regularly, with high definition and good coloring effect.

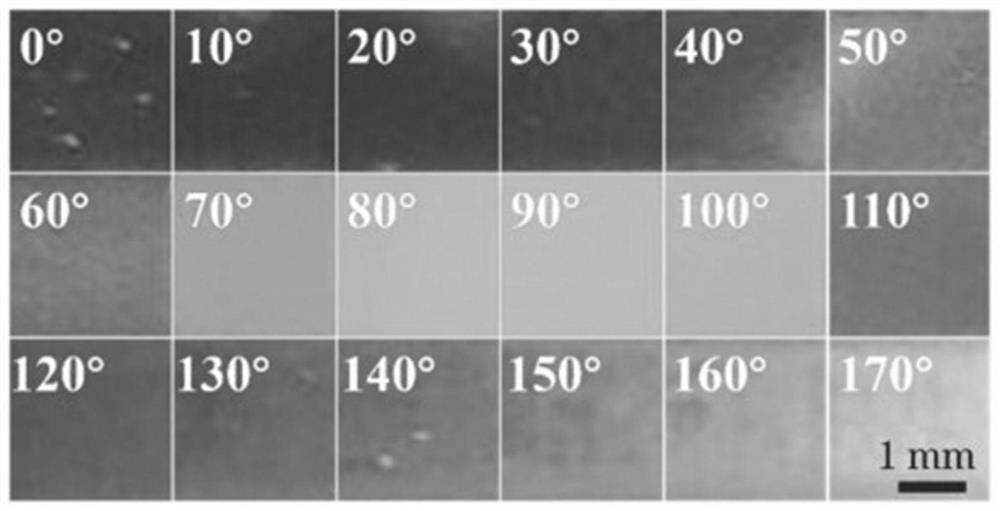

[0051] 3) Synchronous polarization control technology to prepare periodic nanostructure patterns and coloring on free-form surfaces

[0052] The stainless steel sample was placed in e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com