Polishing machine for bucket tooth casting

A technique for polishing machines and bucket teeth, which is applied in grinding/polishing equipment, grinding/polishing safety devices, and machine tools suitable for grinding the edge of workpieces, etc. It can solve problems such as troublesome operation and low efficiency, and achieve effective collection, Effect of increasing polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

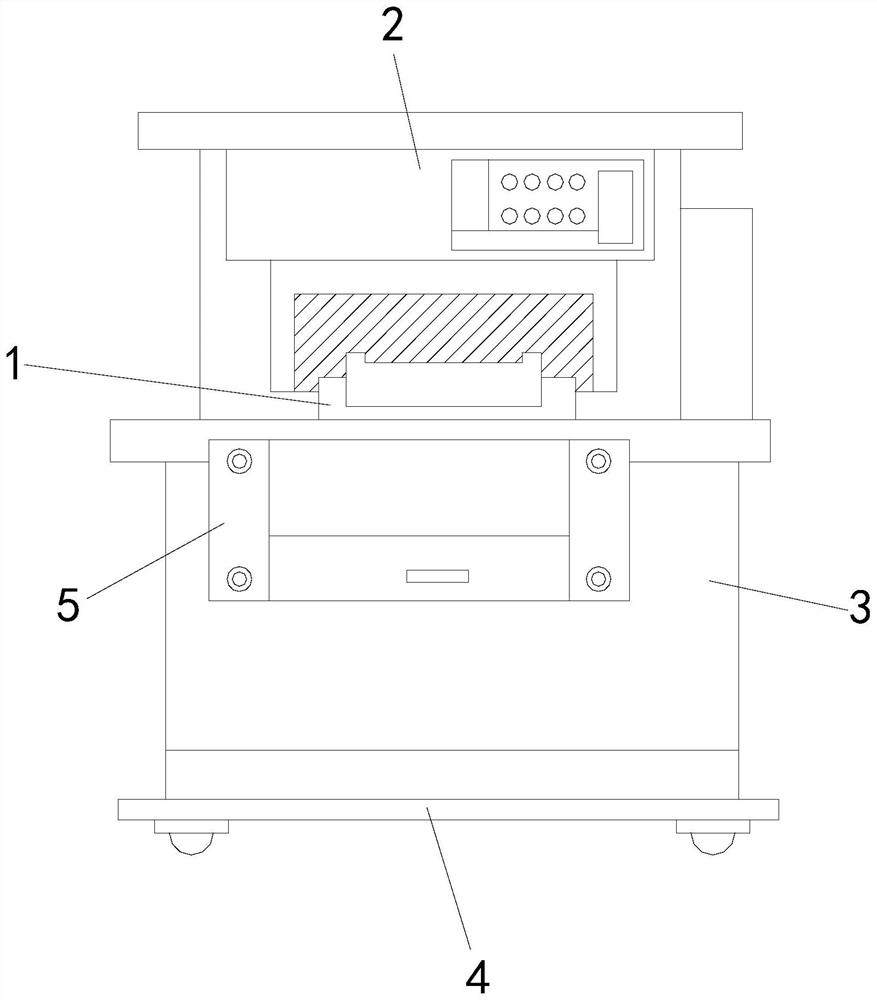

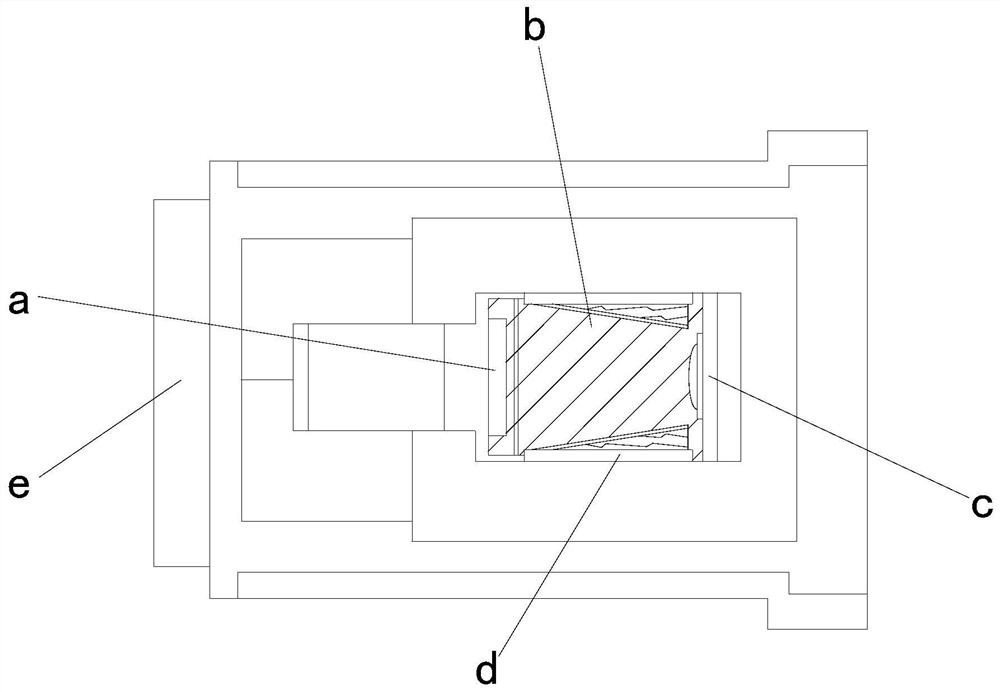

[0025] see Figure 1-Figure 3 , the present invention provides a technical solution for a polishing machine for bucket tooth casting: its structure includes: a polishing tank body 1, a console 2, a loading frame 3, a moving base 4, and a power unit 5, and the moving base 4 is installed on the loading frame 3 Below and locked with the loading frame 3, the upper end of the loading frame 3 is embedded with a power device 5, and the upper end of the power device 5 is provided with a polishing tank body 1, and the polishing tank body 1 is fastened with the power device 5, and the polishing tank body 1 is connected with the power device 5. A console 2 is provided above the tank body 1 and is electrically connected to the console 2. The polishing tank body 1 includes a polishing sleeve device a, a contact plate device b, a buffer plate c, a stabilizing splint d, and a loader compartment e. The splint d is installed on both sides of the contact plate device b and fastened with the con...

no. 2 example

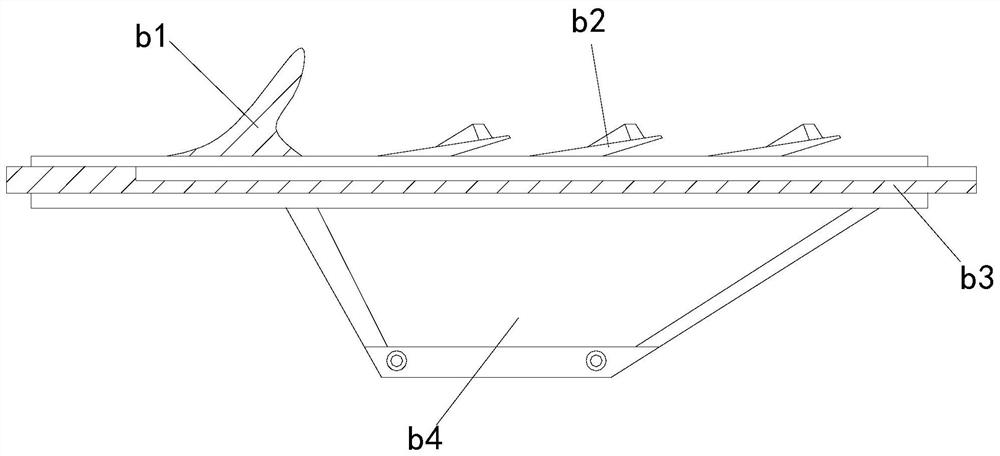

[0029] see Figure 4-Figure 5 , the present invention provides a technical solution for a polishing machine for bucket tooth casting: its structure includes: the polishing sleeve device a includes a polishing disc device a1, a turning wheel a2, a telescopic rod group a3, a partition cover a4, and the telescopic rod group a3 Installed on the outer side of the turning wheel a2 and fastened with the turning wheel a2, the inner side of the turning wheel a2 is provided with a polishing disc device a1, the polishing disc device a1 is buckled with the turning wheel a2, and the upper end of the polishing disc device a1 is locked. Divider cover a4.

[0030] The polishing disc device a1 includes a starting wheel a11, a linkage frame a12, a mating frame a13, an upper throwing wheel a14, and a polishing side wheel set a15. The outer side of the linkage frame a12 is provided with an upper throwing wheel a14, the side of the linkage frame a12 is provided with a mating frame a13, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com