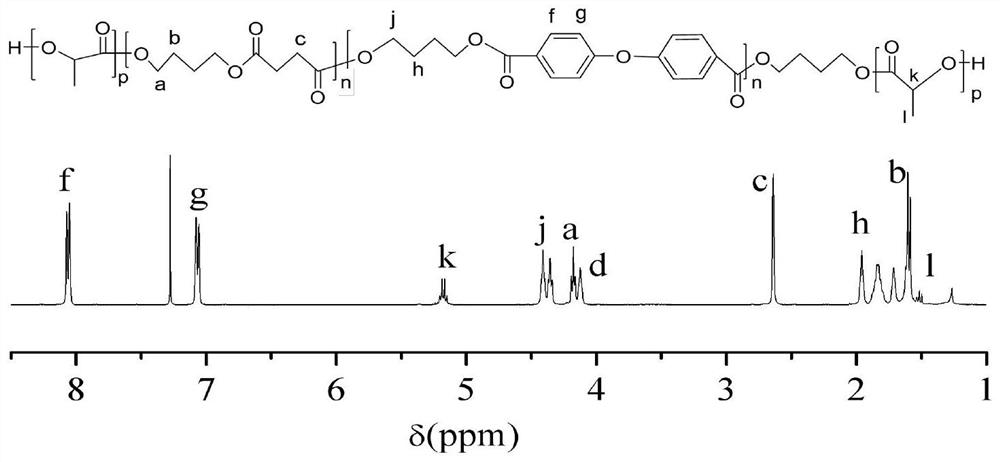

High-resilience polylactic acid segmented copolymer and preparation method thereof

A technology of block copolymer and polylactic acid, which is applied in the field of high resilience polylactic acid block copolymer and its preparation, can solve the problems of complex molecular structure, difficulty in consistent block structure, poor high resilience and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

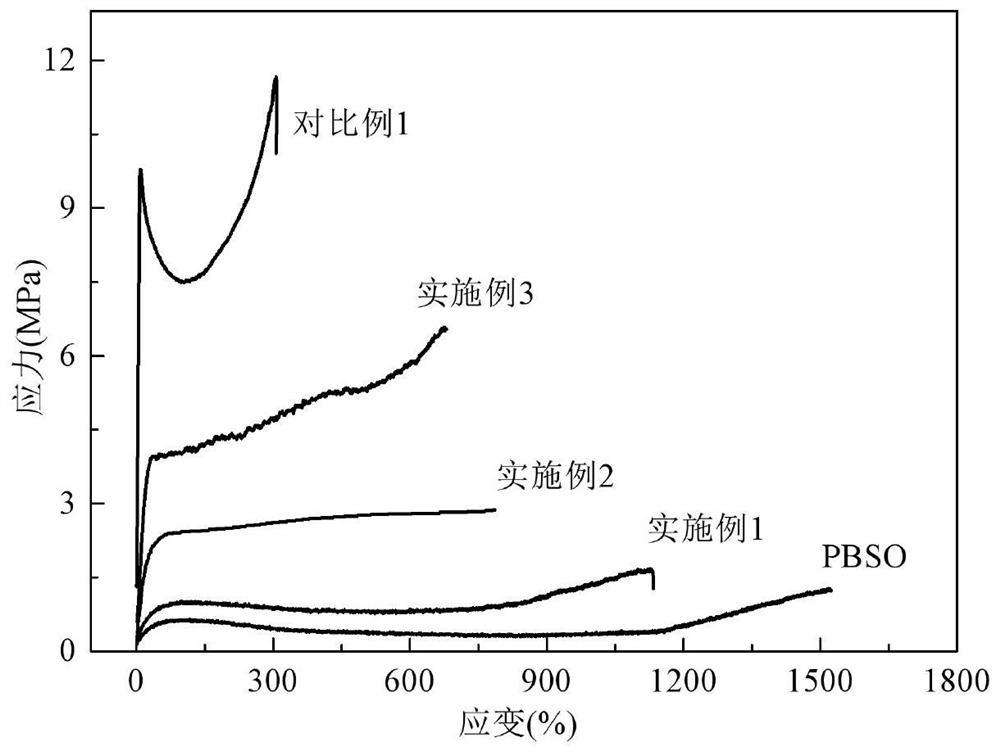

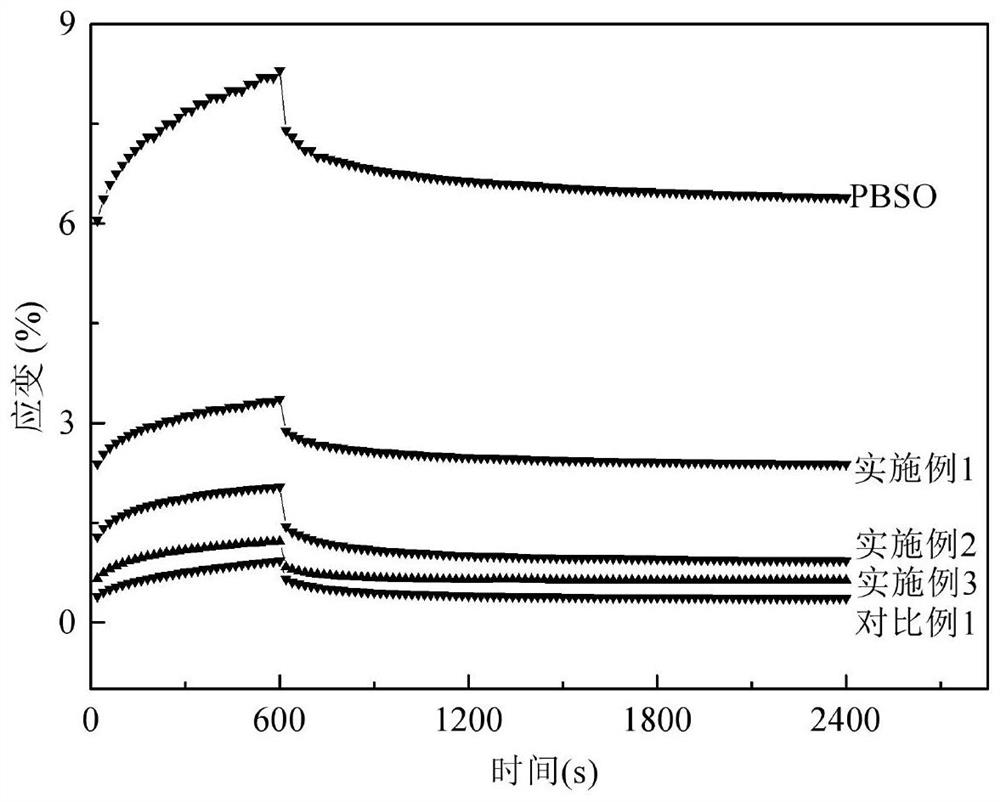

Embodiment 1

[0035]Add 0.48mol (43.26g) of 1,4-butanediol, 0.06mol (7.1g) of succinic acid and 0.06mol (15.49g) of diphenyl ether dicarboxylic acid into a stirring device with a condensing 250ml three-necked flask of a device and a nitrogen protection device; 0.2g of catalyst tetrabutyl titanate (0.5% of the molar amount of the acid monomer) was added dropwise into the three-necked flask. Open the condensate, pass into N 2 , heated up to 180°C, and after the monomers were completely melted, the esterification reaction was carried out with constant temperature stirring for 3-4 hours to complete the esterification reaction stage; then the condensing device was removed and replaced with a pump equipped with a safety bottle, a McGauge vacuum gauge and an oil pump Vacuum device, conduct polycondensation stage, heat up to 220°C, continue reaction for 3 hours, system vacuum degree is 50-80Pa, collect product at room temperature, dissolve product with chloroform, precipitate with methanol, filter ...

Embodiment 2

[0038] Add 0.48mol (43.26g) of 1,4-butanediol, 0.06mol (7.1g) of succinic acid and 0.06mol (15.49g) of diphenyl ether dicarboxylic acid into a stirring device with a condensing 250ml three-necked flask of a device and a nitrogen protection device; 0.2g of catalyst tetrabutyl titanate (0.5% of the molar amount of the acid monomer) was added dropwise into the three-necked flask. Open the condensate, pass into N 2 , heated up to 180°C, and after the monomers were completely melted, the esterification reaction was carried out with constant temperature stirring for 3-4 hours to complete the esterification reaction stage; then the condensing device was removed and replaced with a pump equipped with a safety bottle, a McGauge vacuum gauge and an oil pump Vacuum device, carry out polycondensation stage, heat up to 220°C, continue to react for 4 hours, the vacuum degree of the system is 50-80Pa, collect the product at room temperature, dissolve the product in chloroform, precipitate wi...

Embodiment 3

[0041] Add 0.48mol (43.26g) of 1,4-butanediol, 0.06mol (7.1g) of succinic acid and 0.06mol (15.49g) of diphenyl ether dicarboxylic acid into a stirring device with a condensing 250ml three-necked flask of a device and a nitrogen protection device; 0.2g of catalyst tetrabutyl titanate (0.5% of the molar amount of the acid monomer) was added dropwise into the three-necked flask. Open the condensate, pass into N 2 , heated up to 180°C, and after the monomers were completely melted, the esterification reaction was carried out with constant temperature stirring for 3-4 hours to complete the esterification reaction stage; then the condensing device was removed and replaced with a pump equipped with a safety bottle, a McGauge vacuum gauge and an oil pump Vacuum device, carry out polycondensation stage, heat up to 220°C, continue the reaction for 5 hours, the system vacuum is 50-80Pa, collect the product at room temperature, dissolve the product in chloroform, precipitate with methano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com