High-temperature textile exhaust gas waste heat converting and transfer pipe

A transmission tube and transmission pipeline technology, which is applied in the field of high-temperature textile waste gas waste heat conversion and transmission tube, can solve problems such as reducing the heat collection efficiency of textile waste gas, and achieve the effects of increasing the contact area, improving the collection efficiency, and improving the collection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

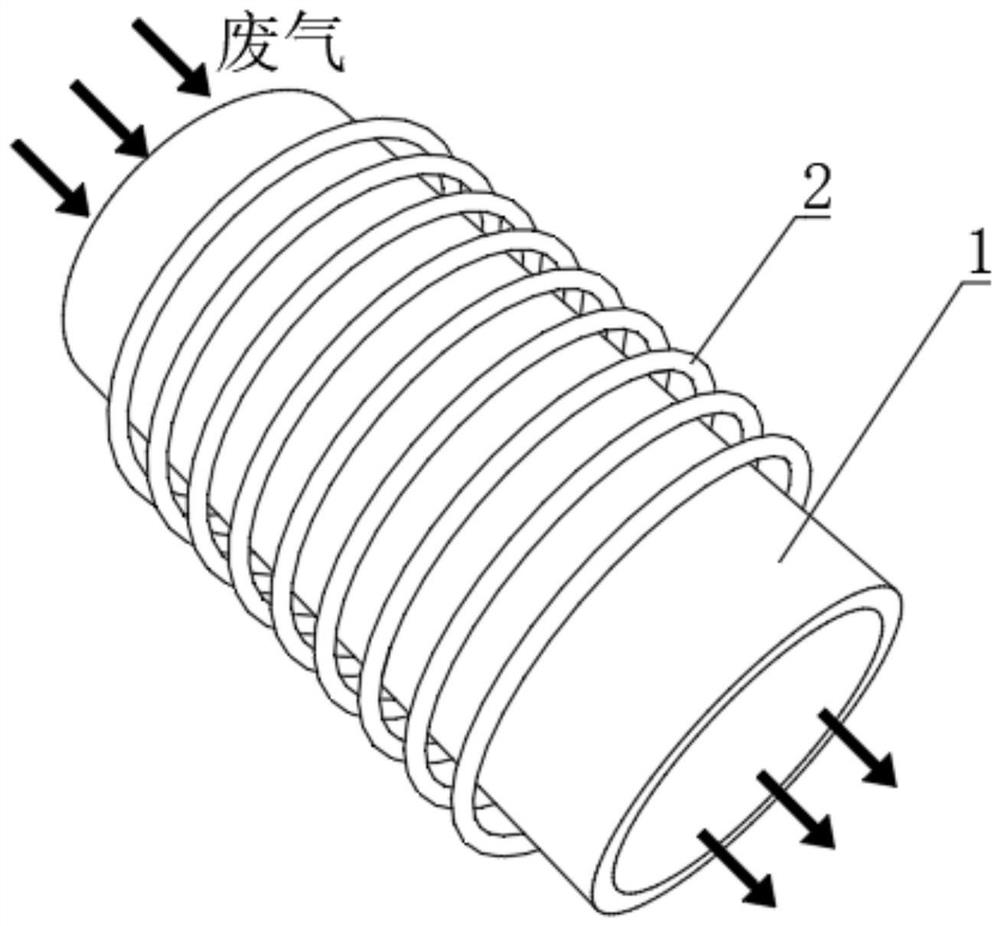

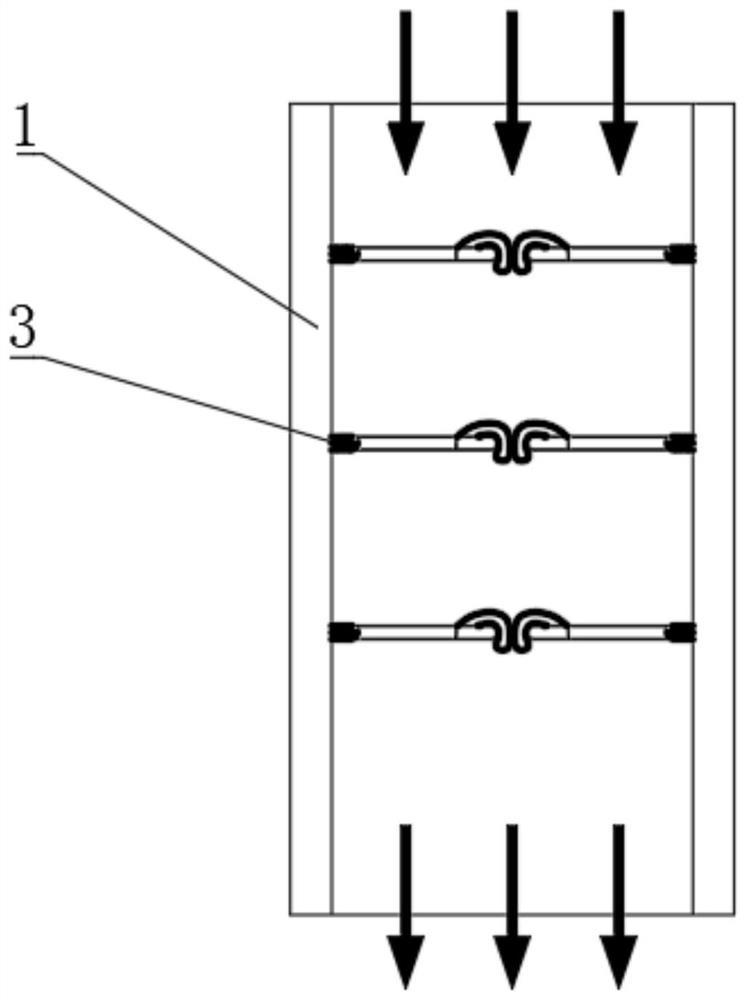

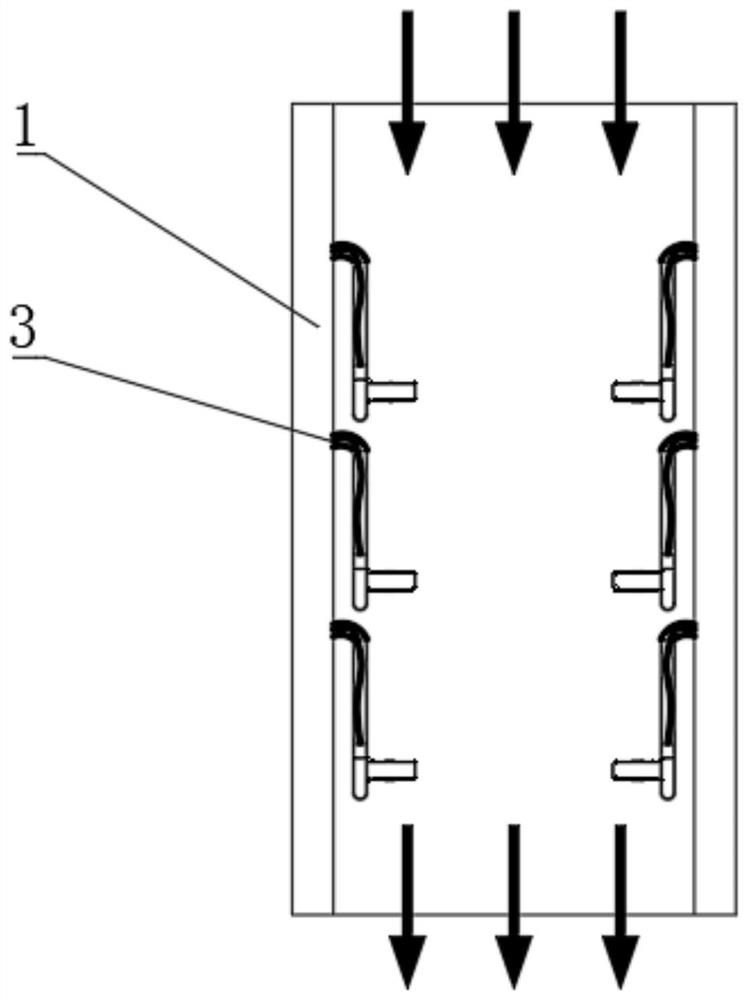

[0043] see Figure 1-6 , a high-temperature textile waste gas waste heat conversion transmission pipe, comprising a waste gas transmission pipe 1, the outer end of the waste gas transmission pipe 1 is provided with a heat collection spiral pipe 2, and during use, cold water continuously flows in the heat collection spiral pipe 2 for use Collect the heat in the textile waste gas in the waste gas transmission pipeline 1. The temperature of the textile waste gas is 65-85°C. The inner wall of the waste gas transmission pipeline 1 is fixedly connected with a plurality of uniformly distributed heat storage carriers 3. The heat storage carriers 3 include the waste gas transmission pipeline 1. The elastic hose 4 on the inner wall, the end of the elastic hose 4 away from the inner wall of the exhaust gas transmission pipeline 1 is fixedly connected with the metal connecting cylinder 5, and the metal connecting cylinder 5 is slidingly connected with the counterweight piston 6, between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com