Method for evaluating suitable degassing time of XLPE flat plate sample or cable

A flat sample, time technology, applied in the field of high voltage and insulation, can solve problems such as difficulty in estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The content of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

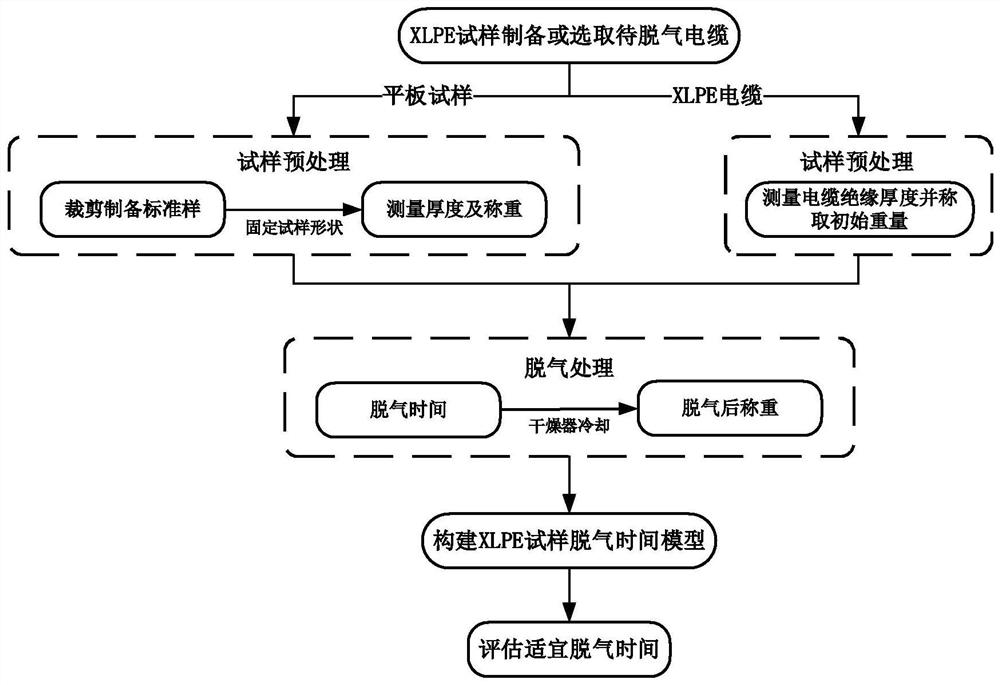

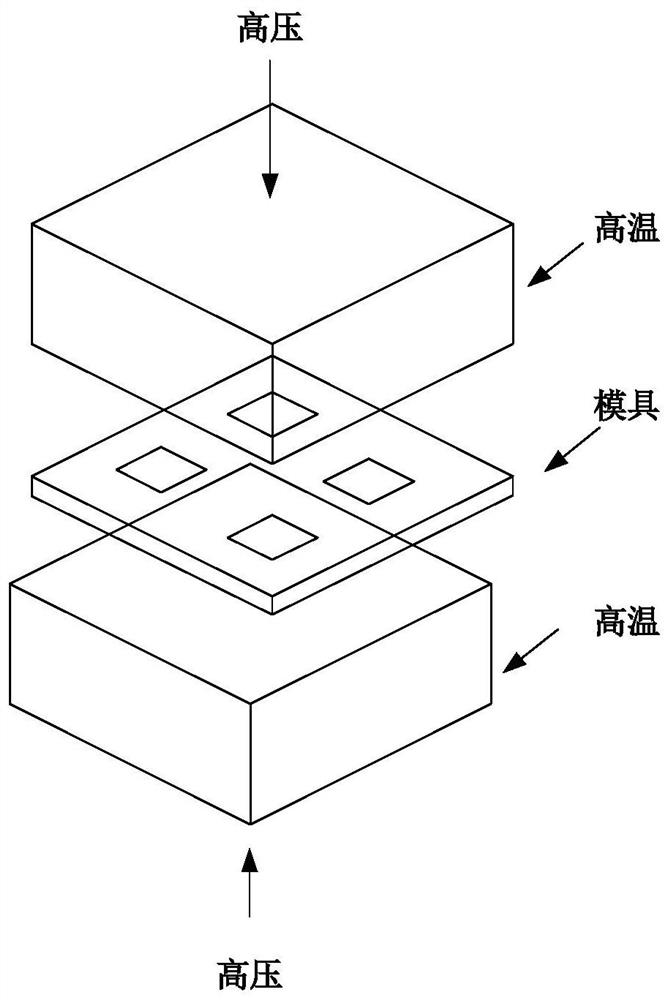

[0065] Step 1, such as figure 2 Shown is a schematic diagram of the preparation of samples by XLPE flat hot pressing method. The XLPE sample is prepared by the standard flat hot pressing method. In this embodiment, a stainless steel plate with 4 hollow squares is selected as the mold. The mold is 25×25×0.2mm, and the hollow size is 10×10×0.2mm; each square Put about 2.5g of XLPE particles into the mold and evenly disperse in the mold. The upper and lower surfaces of the mold are covered with PET. Put the mold on the flat clamp and put it into the vulcanizer together; Under pressure, vulcanize at 180 degrees for 15 minutes, then cool the mold, take out the samples, and prepare 8 samples in total.

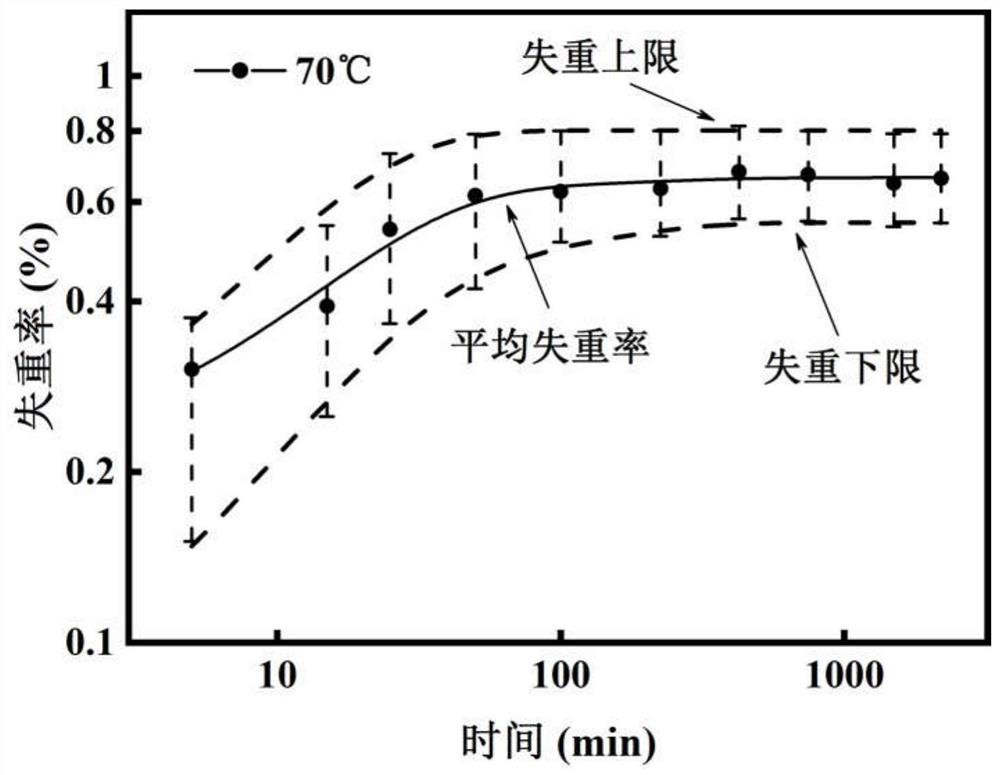

[0066] Since the thickness of the flat sample is far smaller than the length and width of the sample, the diffusion of the cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com