Ultraviolet photodiode based on NiFe2O4/Ga2O3 and preparation method of ultraviolet photodiode

A technology of diodes and ultraviolet light, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as the inability to prepare Ga and lack of materials, and achieve high critical breakdown electric field strength, excellent detection performance, and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

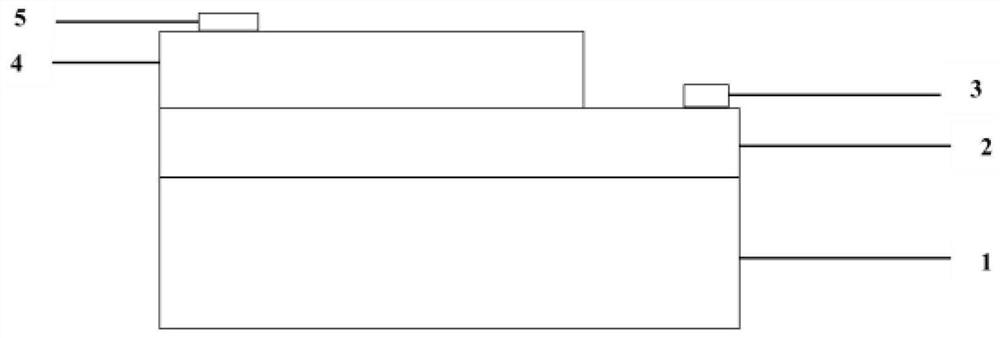

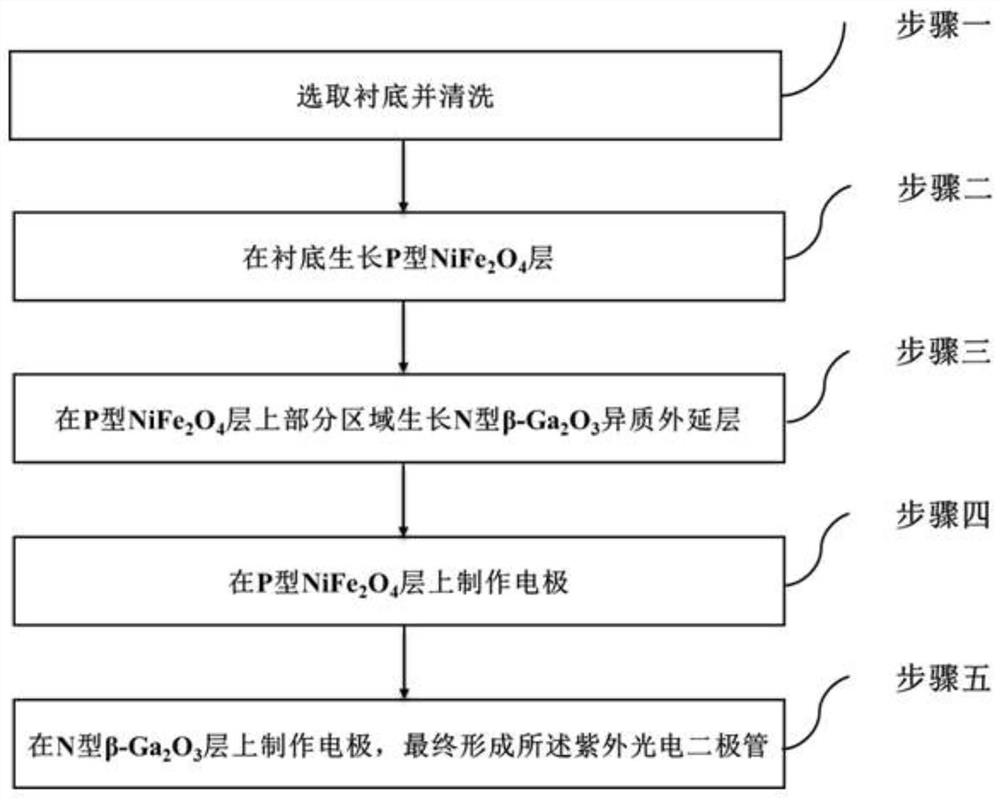

[0054] A NiFe-based 2 o 4 / Ga 2 o 3 The preparation method of the ultraviolet photodiode, flow chart such as figure 2 As shown, the specific steps are as follows:

[0055] Step 1, cleaning the substrate 1, and drying it with nitrogen gas for later use;

[0056] The cleaning process in step 1 is: use cleaning solution-acetone-alcohol-deionized water to clean the sample step by step.

[0057] Step 2, carry out P-type NiFe on the substrate 1 after step 1 cleaning 2 o 4 layer growth;

[0058] P-type NiFe on substrate 1 in step 2 2 o 4 Magnetron sputtering equipment is used for layer growth, with NiFe 2 o 4 The ceramic material is used as the target material, with argon Ar and oxygen O 2 As a sputtering gas, Ar:O during sputtering 2 The ratio is 10:1, the substrate temperature is 500°C, the sputtering pressure is controlled at 0.5Pa, the sputtering power is controlled at 100W, and the sputtering time is controlled at 0.1 hour, and then the sputtered samples are anneal...

Embodiment 2

[0071] A NiFe-based 2 o 4 / Ga 2 o 3 The preparation method of the ultraviolet photodiode, flow chart such as figure 2 As shown, the specific steps are as follows:

[0072] Step 1, cleaning the substrate 1, and drying it with nitrogen gas for later use;

[0073] The cleaning process in step 1 is: use cleaning solution-acetone-alcohol-deionized water to clean the sample step by step.

[0074] Step 2, carry out P-type NiFe on the substrate 1 after step 1 cleaning 2 o 4 layer growth;

[0075] P-type NiFe on substrate 1 in step 2 2 o 4 Magnetron sputtering equipment is used for layer growth, with NiFe 2 o 4 The ceramic material is used as the target material, with argon Ar and oxygen O 2 As a sputtering gas, Ar:O during sputtering 2 The ratio is 5:1, the substrate temperature is 600°C, the sputtering pressure is 5Pa, the sputtering power is 200W, and the sputtering time is 5 hours. After that, the sputtered samples are annealed in the air environment. The temperature...

Embodiment 3

[0088] A NiFe-based 2 o 4 / Ga 2 o 3 The preparation method of the ultraviolet photodiode, flow chart such as figure 2 As shown, the specific steps are as follows:

[0089] Step 1, cleaning the substrate 1, and drying it with nitrogen gas for later use;

[0090] The cleaning process in step 1 is: use cleaning solution-acetone-alcohol-deionized water to clean the sample step by step.

[0091] Step 2, carry out P-type NiFe on the substrate 1 after step 1 cleaning 2 o 4 layer growth;

[0092] P-type NiFe on substrate 1 in step 2 2 o 4 Magnetron sputtering equipment is used for layer growth, with NiFe 2 o 4 The ceramic material is used as the target material, with argon Ar and oxygen O 2 As a sputtering gas, Ar:O during sputtering 2 The ratio is 8:1, the substrate temperature is 550°C, the sputtering pressure is 3Pa, the sputtering power is 150W, and the sputtering time is 3 hours. After that, the sputtered samples are annealed in the air environment. The temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com