Hydrophilic/hydrophobic membrane electrode of ionic liquids

A hydrophobic membrane electrode, ionic liquid technology, applied in battery electrodes, circuits, fuel cells, etc., can solve the problems of increasing charge transfer resistance ohmic resistance, affecting the proton transport performance of membrane electrodes, and affecting the mechanical properties of proton exchange membranes, etc. Stabilization, improved ion transport capacity and stability, the effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

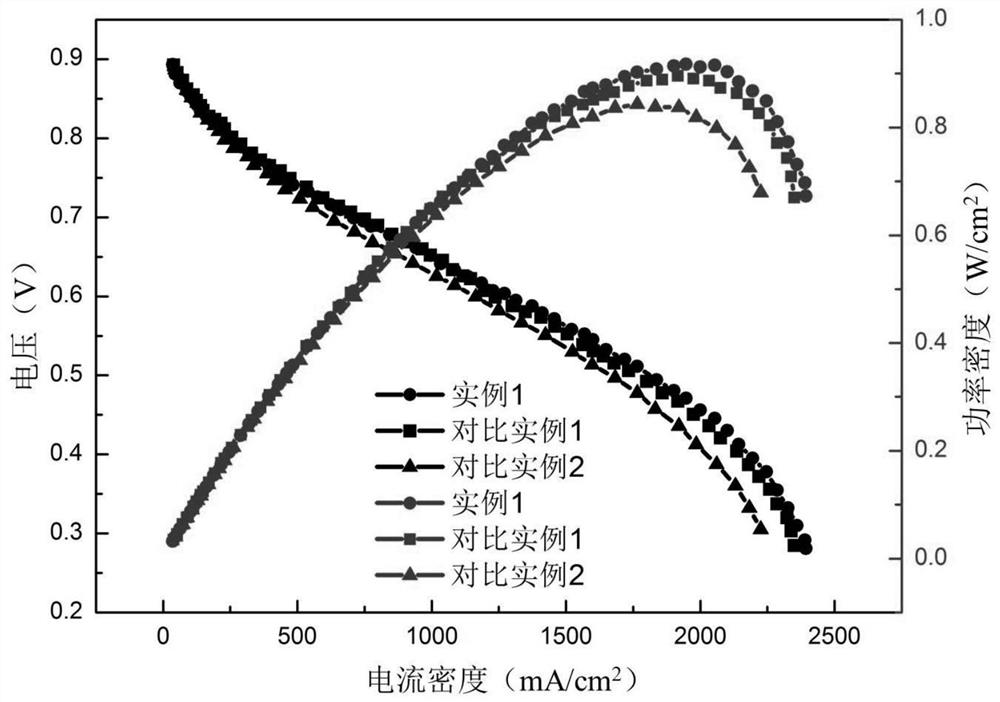

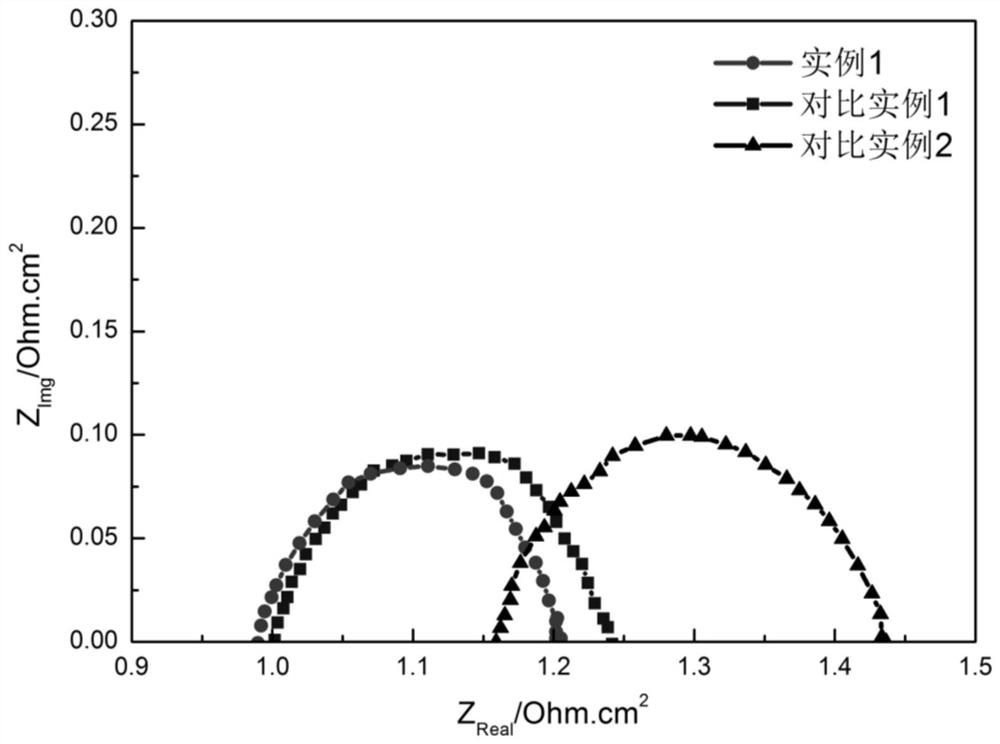

example 1

[0033] A kind of hydrophilic / hydrophobic membrane electrode related to ionic liquid, its preparation method is:

[0034] (1) Proton exchange membrane treatment

[0035] Place the proton exchange membrane in 8% hydrogen peroxide solution, place it at 80°C for 1 hour, then place it in 1mol / L sulfuric acid solution at 80°C for one hour, wash off the sulfuric acid solution with deionized water, and place it Stand-by in deionized water;

[0036] (2) Anode catalyst slurry preparation

[0037] The ionic liquid [MTBD] [BF 4 ], Pt / C catalyst, isopropanol solvent, and Nafion solution were placed in a glass bottle, wherein the ionic liquid [MTBD][BF 4 ], the mass percentages of Pt / C catalyst, isopropanol solvent, and Nafion solution are respectively 0.3%, 1.7%, 95%, and 3%, and ultrasonically disperses for 30 minutes to obtain a uniformly dispersed anode catalyst slurry;

[0038] (3) Preparation of cathode catalyst slurry

[0039]①The ionic liquid [MTBD][NTf 2 ], isopropanol solven...

example 2

[0054] A kind of hydrophilic / hydrophobic membrane electrode related to ionic liquid, its preparation method is:

[0055] (1) Proton exchange membrane treatment

[0056] Same as example 1;

[0057] (2) Anode catalyst slurry preparation

[0058] On the basis of Example 1, the ionic liquid is replaced by [MTBD][HSO 4 ], the catalyst is replaced by Pt-Co / C;

[0059] (3) Preparation of cathode catalyst slurry

[0060] On the basis of Example 1, the ionic liquid is replaced by [MTBD][PF 6 ], catalyst is replaced by Pt-Co / C, and other steps are with example 1;

[0061] (4) Catalyst slurry coating

[0062] Evenly coat the prepared anode catalyst slurry and cathode catalyst slurry on both sides of the treated proton exchange membrane at a coating temperature of 80°C, where the Pt loading on the anode side is controlled at 0.02mgPt / cm 2 , the Pt loading on the cathode side is controlled at 0.1mgPt / cm 2 , the ionic liquid accounts for 20% by mass on both the anode side and the ca...

example 3

[0064] A kind of hydrophilic / hydrophobic membrane electrode related to ionic liquid, its preparation method is:

[0065] (1) Proton exchange membrane treatment

[0066] Same as example 1;

[0067] (2) Anode catalyst slurry preparation

[0068] On the basis of Example 1, the ionic liquid is replaced by [MTBD][H 2 PO 4 ], the catalyst is replaced by Pt-Ni / C;

[0069] (3) Preparation of cathode catalyst slurry

[0070] On the basis of example 1, catalyst replaces Pt-Ni / C, and other steps are with example 1;

[0071] (4) Catalyst slurry coating

[0072] The prepared anode catalyst slurry and cathode catalyst slurry were evenly coated on both sides of the treated proton exchange membrane at a coating temperature of 80°C, and the Pt loading on the anode side was controlled at 0.05mgPt / cm 2 , the Pt loading on the cathode side is controlled at 0.15mgPt / cm 2 , the ionic liquid accounts for 50% by mass on both the anode side and the cathode side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com