A microwave treatment method for pharmaceutical waste

A microwave treatment and waste technology, which is applied in the direction of protection devices against harmful chemicals, can solve problems such as secondary pollution of dioxins, and achieve the effects of reducing energy consumption and processing costs, stable process, and controllable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

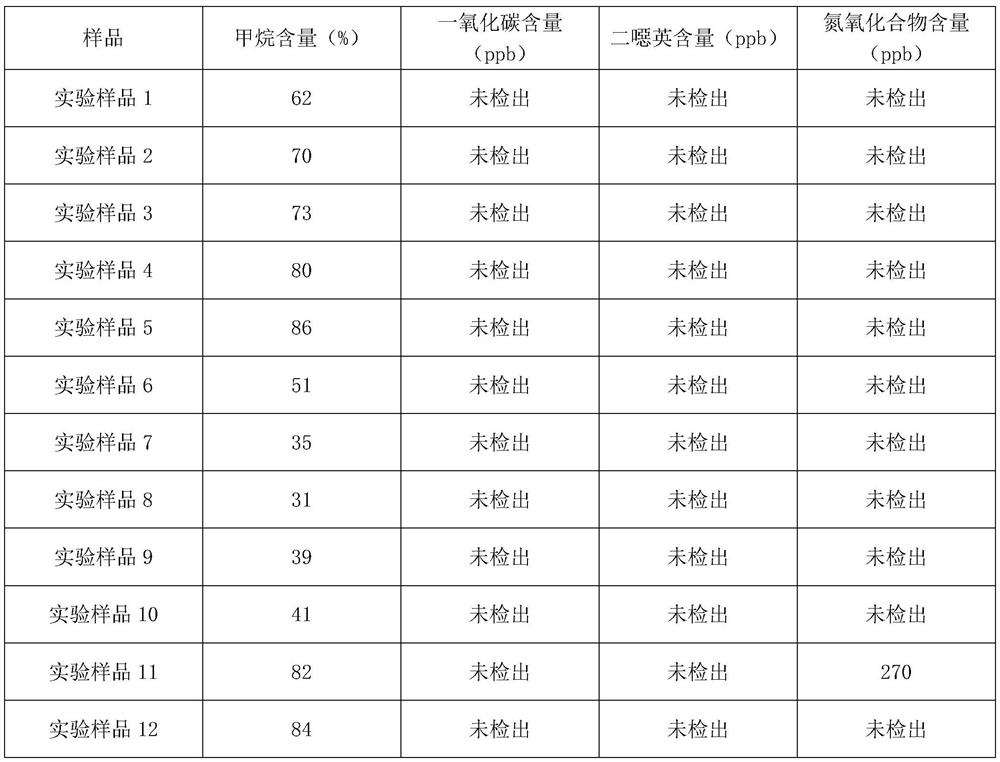

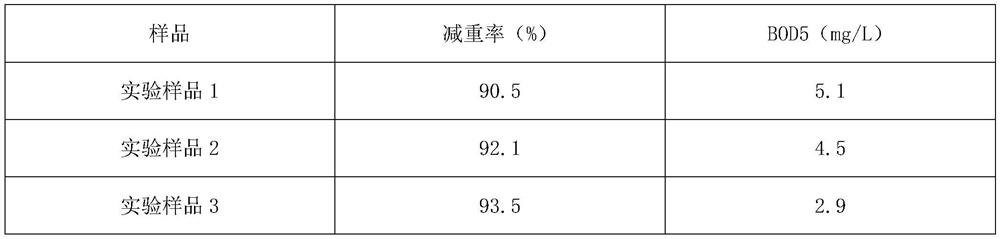

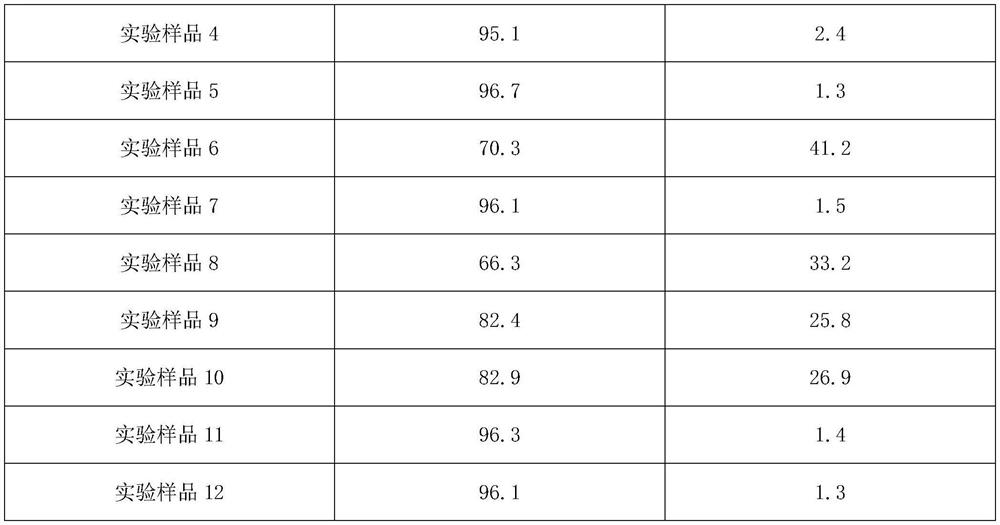

Examples

Embodiment 1

[0031] A microwave treatment method for pharmaceutical waste, comprising the following steps:

[0032] a. Put the pharmaceutical waste into the microwave cracking furnace, feed in biogas, heat up to 70°C, keep warm for 50 minutes, then add nitric acid waste liquid, heat up to 155°C and keep warm for 85 minutes to obtain the pre-digested product;

[0033] Among them, the biogas was fed continuously for 23 minutes, and the flow rate was 1.4L / min; the amount of nitric acid waste liquid added was 1 / 30 of the mass of pharmaceutical waste, and the mass percentage concentration of nitric acid in the nitric acid waste liquid was 25%.

[0034]b. Set the output power of the microwave cracking furnace, and then raise the temperature to 205°C within 25 seconds to perform microwave digestion and α-ray ionization on the pre-digested product. Set the microwave digestion time to 40 minutes to obtain the digestion mixture and digestion gas, and then the digestion gas And the introduced biogas ...

Embodiment 2

[0040] A microwave treatment method for pharmaceutical waste, comprising the following steps:

[0041] a. Put the pharmaceutical waste into the microwave cracking furnace, feed in biogas, raise the temperature to 80°C, keep it warm for 70 minutes, then add nitric acid waste liquid, raise the temperature to 175°C and keep it warm for 125 minutes to obtain the pre-digested product;

[0042] Among them, the biogas was fed continuously for 33 minutes, and the flow rate was 5.6L / min; the amount of nitric acid waste liquid added was 1 / 20 of the mass of pharmaceutical waste, and the mass percentage concentration of nitric acid in the nitric acid waste liquid was 45%.

[0043] b. Set the output power of the microwave cracking furnace, and then raise the temperature to 315°C within 5 seconds to perform microwave digestion and α-ray ionization on the pre-digested product. Set the microwave digestion time to 70 minutes to obtain the digestion mixture and digestion gas, and then the digest...

Embodiment 3

[0049] A microwave treatment method for pharmaceutical waste, comprising the following steps:

[0050] a. Put the pharmaceutical waste into the microwave cracking furnace, feed in biogas, heat up to 72°C, keep warm for 55 minutes, then add nitric acid waste liquid, heat up to 160°C and keep warm for 95 minutes to obtain the pre-digested product;

[0051] Among them, the biogas was fed continuously for 25 minutes, and the flow rate was 2.4L / min; the amount of nitric acid waste liquid added was 1 / 22 of the mass of pharmaceutical waste, and the mass percentage concentration of nitric acid in the nitric acid waste liquid was 30%.

[0052] b. Set the output power of the microwave cracking furnace to 12kw, and then raise the temperature to 232°C within 10 seconds to perform microwave digestion and α-ray ionization on the pre-digested product. Set the microwave digestion time to 47 minutes to obtain the digestion mixture and digestion gas, and then Digestion gas and incoming biogas a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com