Carbide material for cutting devices and associated method of manufacture

A manufacturing method and carbide technology, applied in welding/cutting media/materials, manufacturing tools, additive manufacturing, etc., can solve the problem of limited hardness of tungsten carbide materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

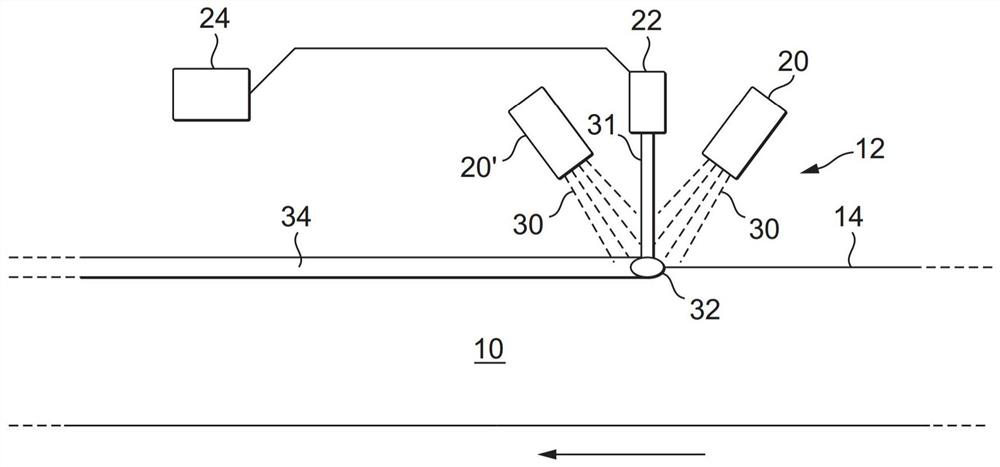

[0028] figure 1 Illustrated is a method of forming carbide material on a device such as a steel strip 10 that can be used as a blade in a tool such as a band saw, hack saw, jig saw, hole saw. The strip 10 may be formed with teeth if desired.

[0029] The strip 10 is moved relative to the station 12 to allow carbide material to form along the upper edge 14 of the strip 10 . Workstation 12 includes hoppers 20, 20' for supplying material in powder form and a high power energy source 22, typically a continuous wave fiber laser with a maximum power of 1 kW operating at 800 W, although the high power energy source 22 can apply a power range from 300W to 2kW. One or more computing devices 24 control the movement of the strip 10 relative to the workstation 12 and hoppers 20 , 20 ′, the supply of material from the hoppers 20 , 20 ′ and the output of the energy source 22 . Typically, the web 10 moves at a substrate traverse speed of 2 m / min, although the traverse speed may vary betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com