A construction technology of heap leaching site based on green mine construction technology

A construction process and heap leaching technology, applied in infrastructure engineering, construction, protection devices, etc., can solve the problems of partial repair and filling that cannot be punctured, geomembrane puncture, mother liquor leakage, etc., to prevent leakage, The effect of speeding up the outflow and accelerating the outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

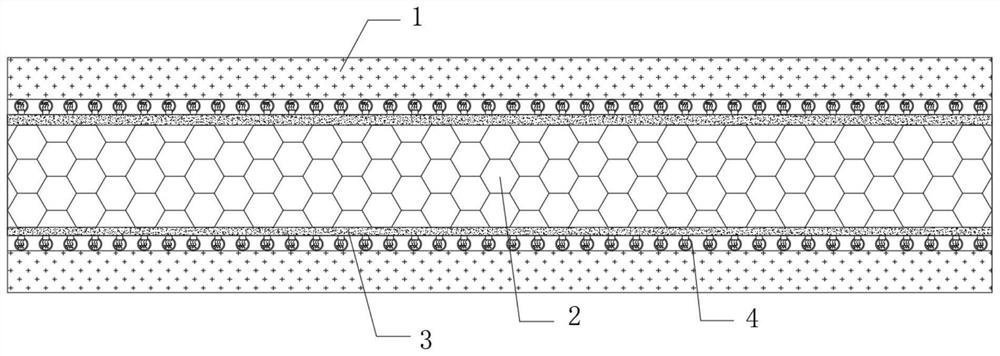

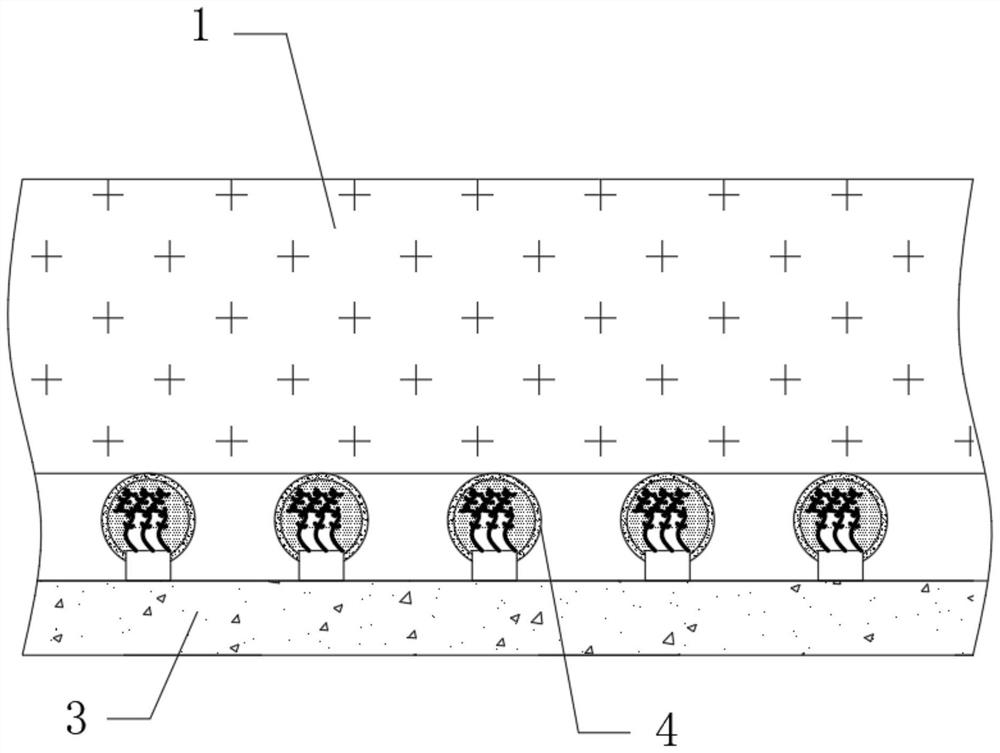

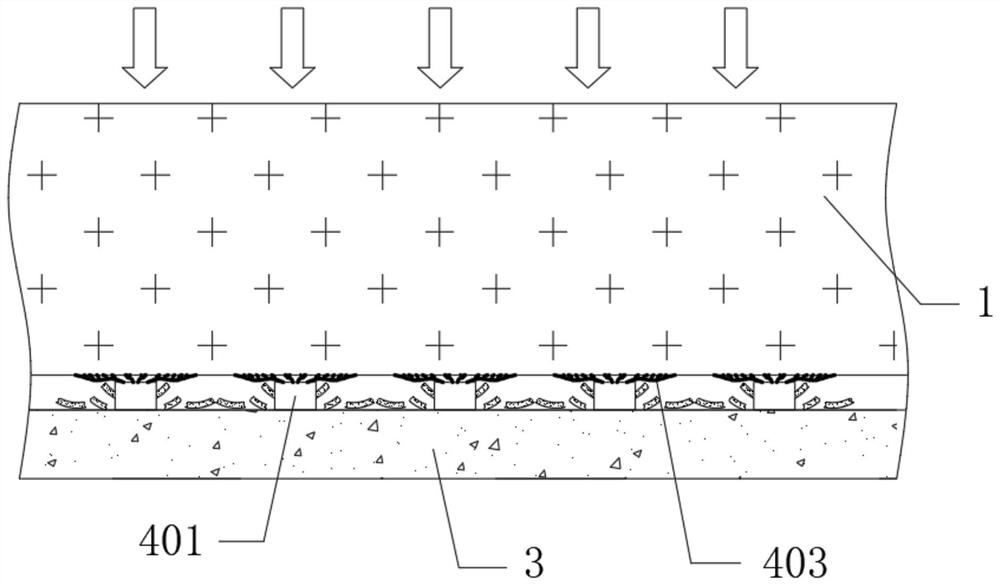

[0044] see Figure 1-7 , a heap leaching site construction process based on green mine construction technology, comprising the following steps:

[0045] S1. After other constructions are completed, level the site of the heap leaching site to remove sharp or protruding stones on the surface;

[0046] S2, laying the first layer of geomembrane 1 first, then laying the anti-seepage layer 2, and finally laying the second layer of geomembrane 1. The upper and lower sides of the anti-seepage layer 2 are fixedly connected with buffer pads 3, and the surface of the buffer pad 3 is fixedly connected with a plurality of adhesive balls 4, and the adhesive balls 4 play the role of connecting the anti-seepage layer 2 with the geomembrane 1 to prevent The anti-seepage layer 2 and the geomembrane 1 are dislocated and slipped. The anti-seepage layer 2 is composed of a plurality of outer honeycombs 201. The inner walls of the two sides of the outer honeycombs 201 are fixedly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com