Refrigerant recovery device of ORC waste heat power generation turbo expander

A turbo-expander, waste heat power generation technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high manufacturing cost, inaccessibility, expensive manufacturing equipment, etc., to reduce manufacturing difficulty and harsh requirements, The effect of avoiding waste of resources and facilitating assembly and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

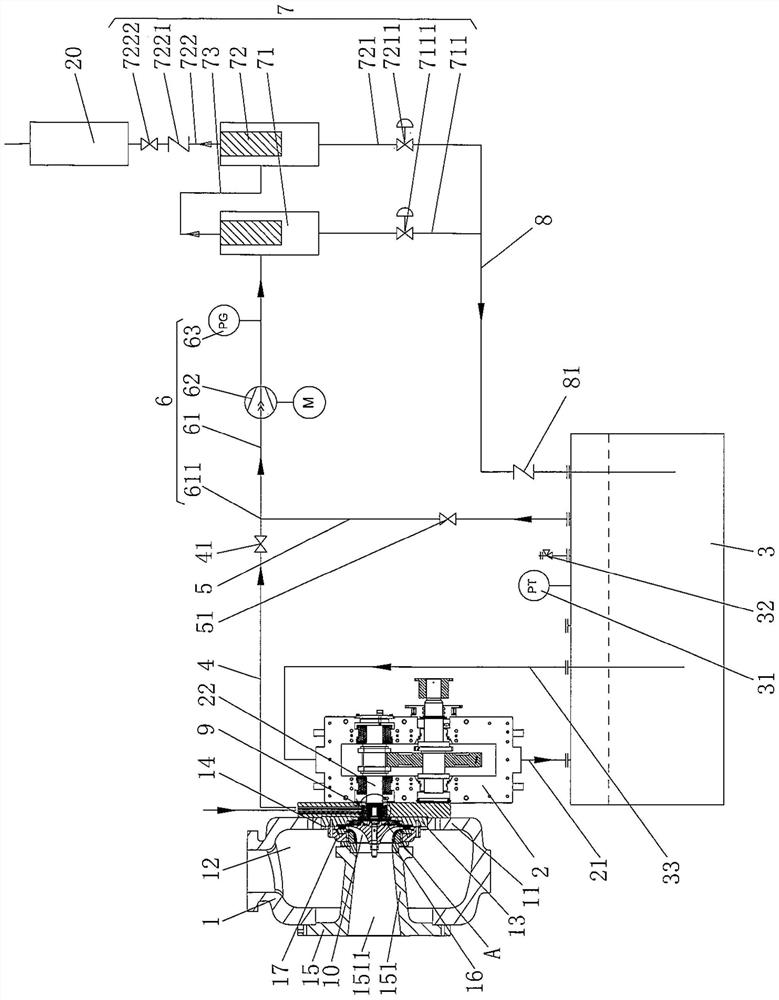

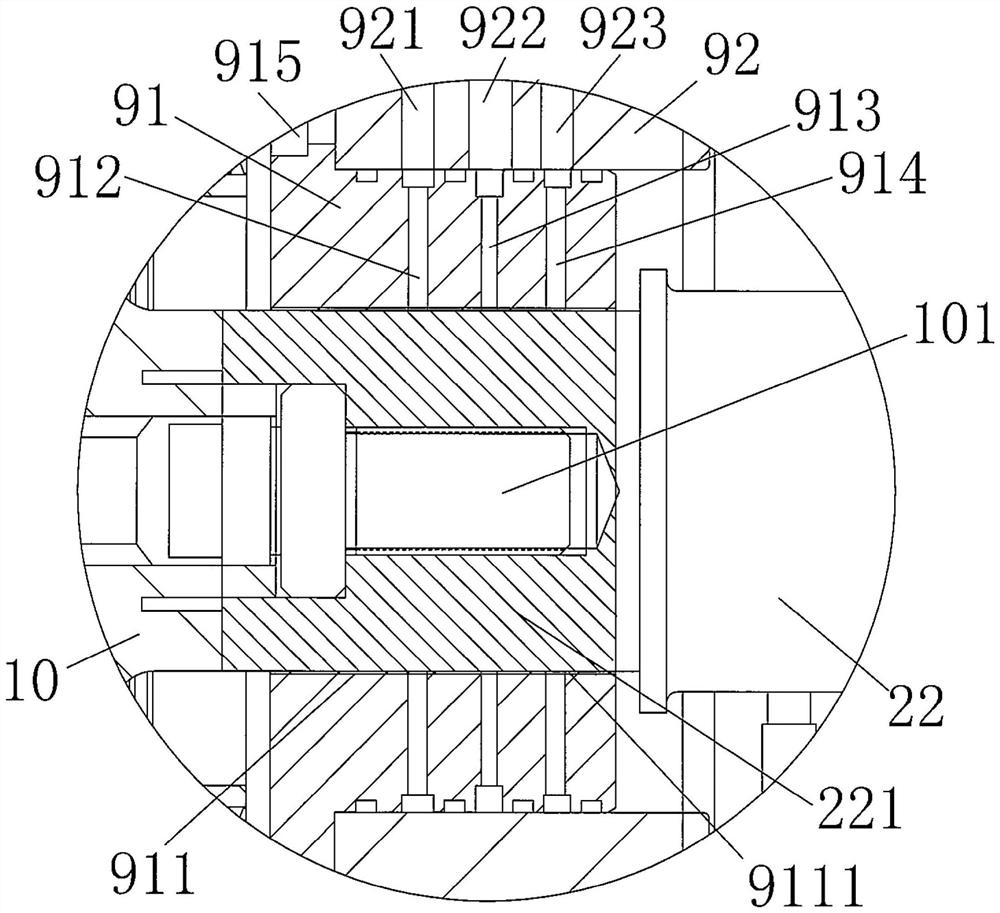

[0021] See figure 1 and figure 2, showing a volute 1, an impeller 10, a gear box 2 and an oil tank 3 of the structural system of the ORC waste heat power generation turbo expander, wherein the gear box 2 and the oil tank 3 belong to the auxiliary facilities of the turbo expander, A nozzle flow adjustment plate 13 is arranged at the center of the side of the volute bottom plate 11 of the volute 1 (that is, the "volute right side plate", the same below) facing the volute cavity 12, and is arranged on the left side of the volute 1. There is an air outlet ring 15, which is sealingly matched with the left side of the volute 1, and an air outlet ring 151 is formed at the center of the air outlet ring 15, and the right end of the air outlet pipe 151 extends into the volute cavity 12 , a sealing sleeve 16 and a nozzle pressure plate 17 are sequentially arranged on the right end of the air outlet pipe 151 of the air outlet ring, the left end of the seal sleeve 16 penetrates into the ...

Embodiment 2

[0037]Only change the aforementioned dry air to nitrogen. Since nitrogen is used as the sealed dry gas, the gas mixed with R134a and nitrogen is essentially a mixed gas of R134a and nitrogen. The gas mixed with oil gas and nitrogen is the mixed gas. It is essentially a mixture of oil gas and nitrogen. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com