Method for researching and simulating corrosion resistance of metal matrix doped with alloy elements

A technology of metal matrix and alloy elements, which is applied in the field of materials science, can solve the problems of high cost and long research cycle, and achieve the effects of high accuracy, consistent regularity, and shortened research cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

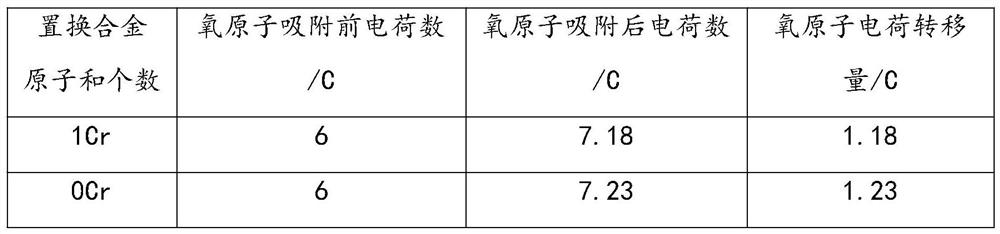

[0102] The alloy atoms in Example 1 are Cr atoms.

[0103] (1) Search through literature (KLAVER T P.Defect and solute properties in dilute Fe-Cr-Ni austenitic alloys from first principles[J].Phys.Rev.B,2012, 85:174111-1-23.) to obtain The lattice constant of face-centered austenite Fe is the lattice constant Import the first-principle calculation software VASP 5.2 to construct the metal matrix model;

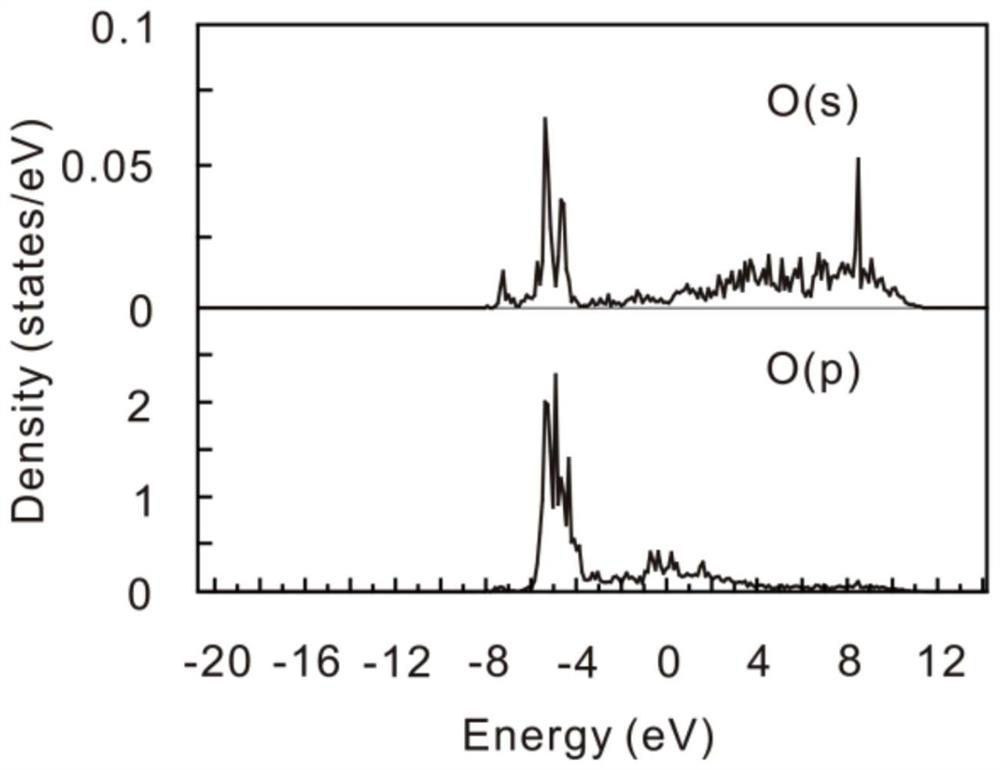

[0104] (2) Replace 1 Fe atom with 1 Cr atom, adsorb 1 oxygen atom, and select medium for the calculation accuracy, so set the supercell size to 3×3×3;

[0105](3) Due to the repeatability of metal atom positions in the Fe matrix supercell, there is only one position where Cr atoms can replace Fe atoms. After energy optimization, a metal replacement model with the most stable spatial position of Cr atoms is obtained;

[0106] (4) Set the surface oxygen atom adsorption positions on the metal replacement model, which are top position (top position), hollow position (vacancy p...

Embodiment 2

[0119] The alloy atoms in Example 2 are Ni atoms.

[0120] (1) Search through literature (I.A.ABRIKOSOV,A.E.KISSAVOS.Competition between magnetic structures in the Fe rich fcc Fe-Ni alloys[J].Phys.Rev.B, 2007,76:014434-1-15.) to obtain the noodle center The lattice constant of austenitic Fe is the lattice constant Import the first-principle calculation software VASP 5.2 to construct the metal matrix model;

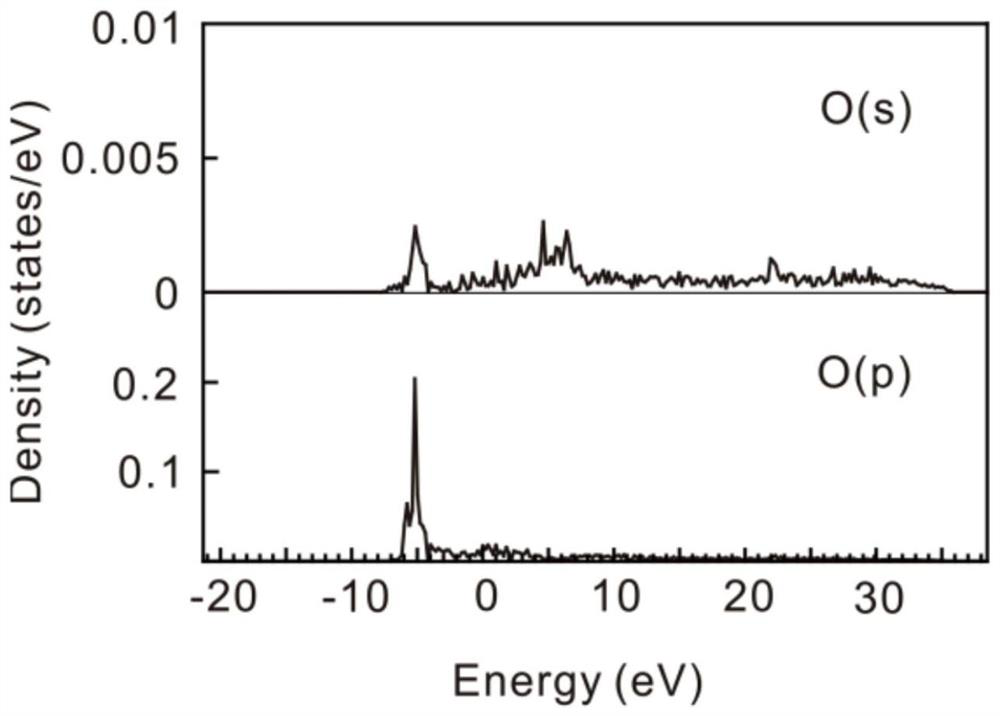

[0121] (2) Replace 1 Fe atom with 1 Ni atom, adsorb 1 oxygen atom, and select medium for the calculation accuracy, so set the supercell size to 3×3×3;

[0122] (3) Due to the repeatability of the position of the metal atom in the supercell of the Fe matrix, there is only one position where the Ni atom replaces the Fe atom. After energy optimization, a metal replacement model with the most stable space position of the Ni atom is obtained;

[0123] (4) Set the surface oxygen atom adsorption positions on the metal replacement model, which are top position (top position),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com