High-pressure reaction kettle and control method thereof

A high-pressure reaction kettle and high-pressure reaction technology, applied in chemical instruments and methods, control/regulating processes, pressure vessels used in chemical processes, etc., can solve the problems of low heating efficiency, limited promotion, low efficiency, etc. Efficiency, time reduction, high efficiency liquefaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

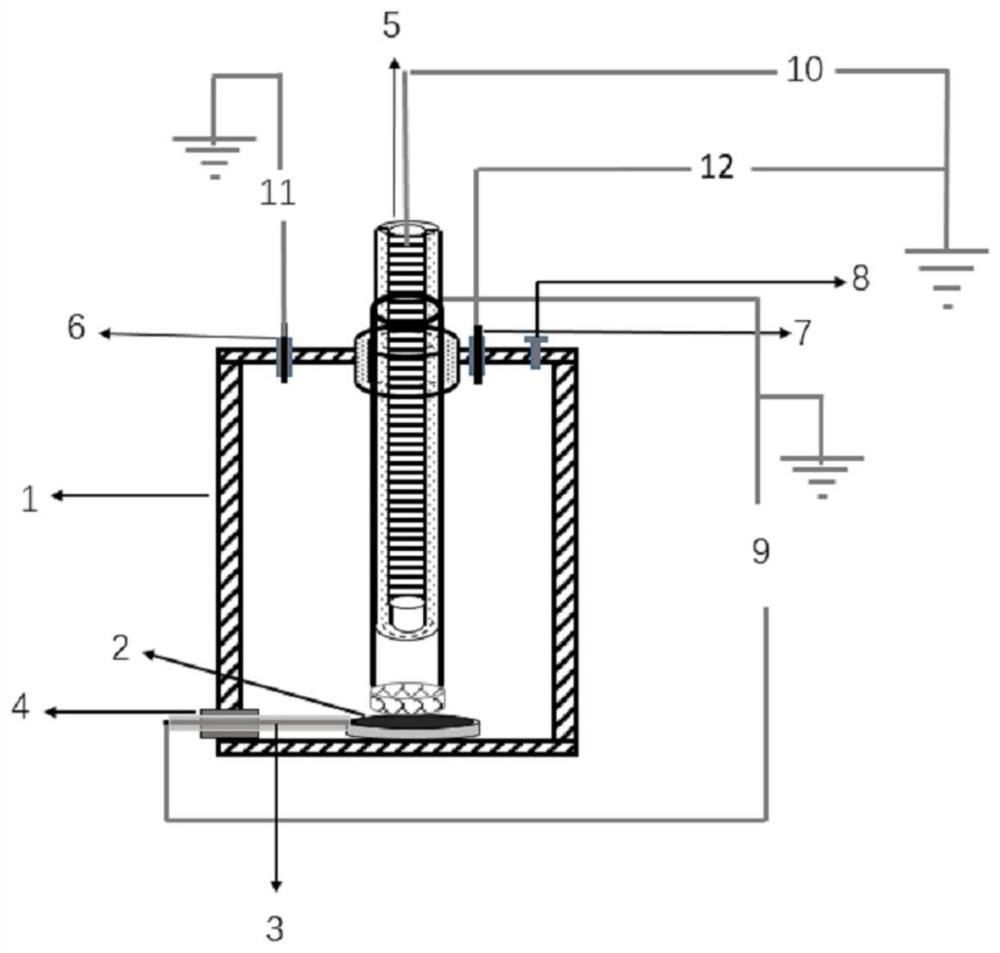

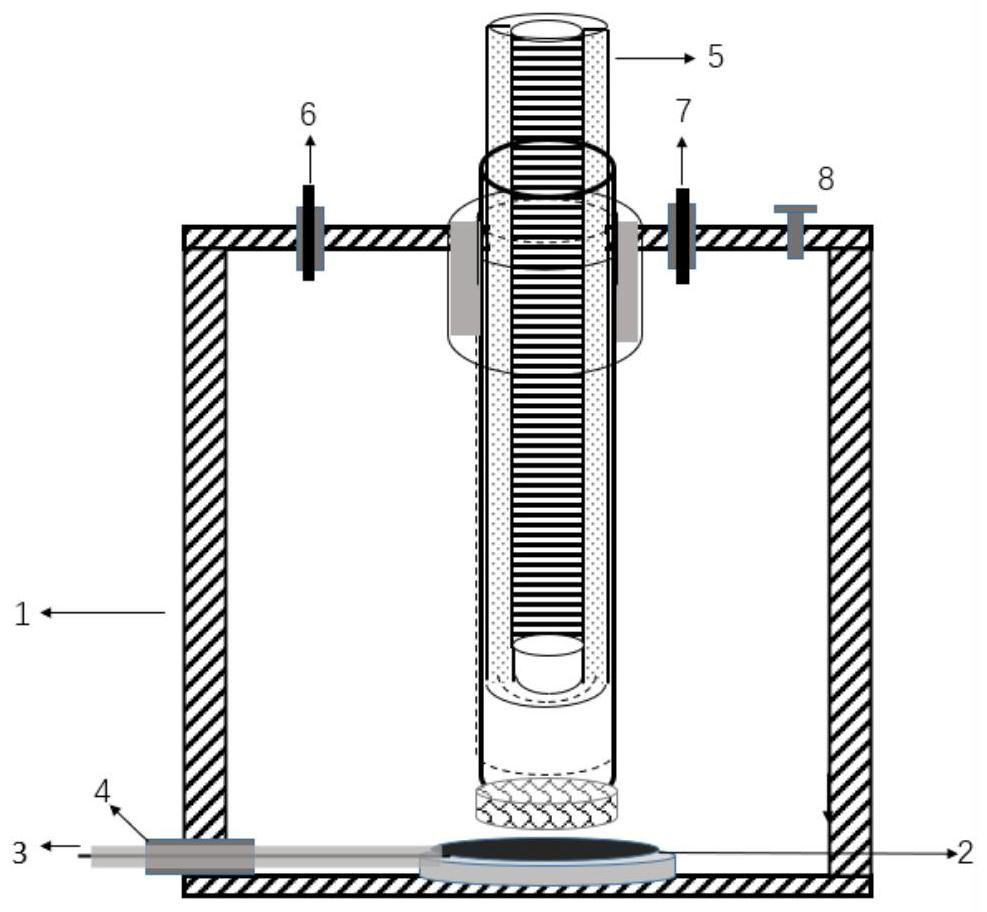

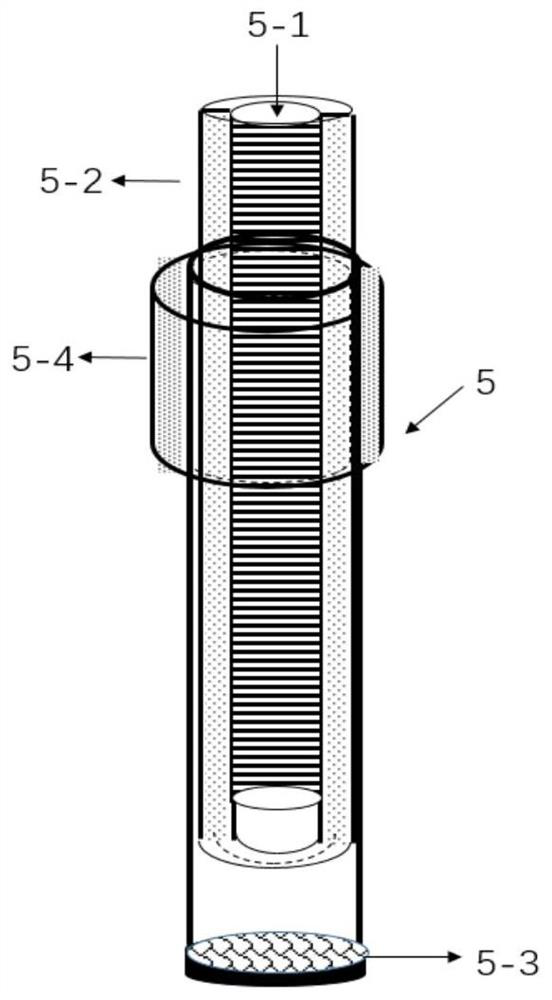

[0033] In order to overcome the shortcomings of large energy loss, low heating efficiency, low free radical content, and low bio-oil quality in the conduction heating process, the present invention improves the autoclave reactor and its control method. The present invention will be described in detail below in conjunction with the accompanying drawings described as follows:

[0034] The present invention improves the structure of the autoclave reactor. The autoclave reactor of the present invention has a high-voltage electrode, a ground electrode, an ultrasonic device, a pressure sensing device and a temperature detection device, and water, biomass and a solvent are added to the reactor to adjust The ultrasonic device and the parameters between the high-voltage electrode and the ground electrode realize the synergistic effect of ultrasonic and plasma, thereby realizing efficient liquefaction of biomass. This synergistic process can increase the content of free radicals and imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com