Bauxite particle desiliconization device and method based on density segregation theory

A technology of bauxite and particles, applied in chemical instruments and methods, solid separation, grain processing, etc., can solve problems such as equipment corrosion, environmental pollution, high heat consumption, etc., and achieve high-efficiency separation, low labor intensity, and simple equipment structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

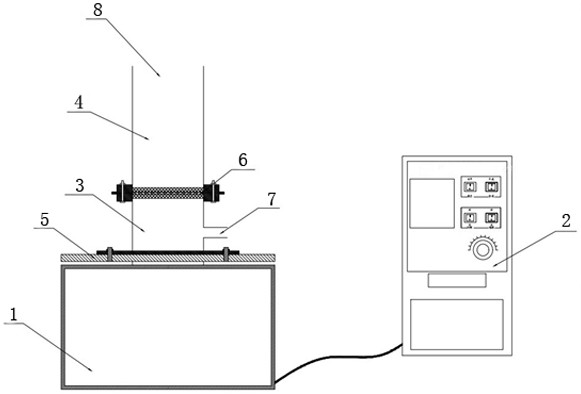

Image

Examples

Embodiment

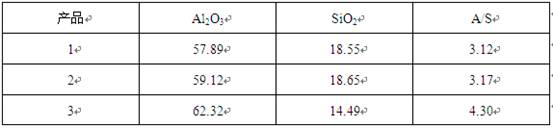

[0039] Taking a low-grade mixed bauxite ore in Shanxi as the test sample, the parameters of the three raw ores are shown in the table below.

[0040]

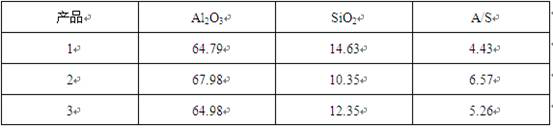

[0041] The specific process of desiliconization is as follows: Shanxi low-grade mixed bauxite is crushed by hammer crusher and XJKEP-2 universal jaw crusher, and then pulverized by XTK-2A sealed laboratory sample preparation pulverizer , and carry out sieving and grading through standard grading sieves; sieving and grading uses standard 20 mesh and 40 mesh grading sieves, after double-layer screening, take two sieve intermediates; then add bauxite particles into the material selection chamber through the feed port, Due to the large difference in the density of aluminum and siliceous bauxite particles, resulting in a large difference in quality, it can be effectively screened in the material selection room; under the dual action of the air chamber and the electromagnetic vibrating table, a strengthened bauxite is created The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com