A method of energy saving and consumption reduction based on the whole process of mine water zero discharge

A mine water, whole-process technology, applied in the field of water treatment, can solve the problems of waste heat from steam condensation and cooling heat exchange, high operating energy consumption and operation and maintenance costs, and low system production efficiency, so as to improve the concentration recovery rate and reduce Fouling risk, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further specifically described below through specific examples. It should be understood that the implementation of the present invention is not limited to the following examples, and any modifications and / or changes made to the present invention will fall within the protection scope of the present invention.

[0033] In the present invention, unless otherwise specified, all parts and percentages are in weight units, and the equipment and raw materials used can be purchased from the market or commonly used in the field. The methods in the following examples, unless otherwise specified, are conventional methods in the art.

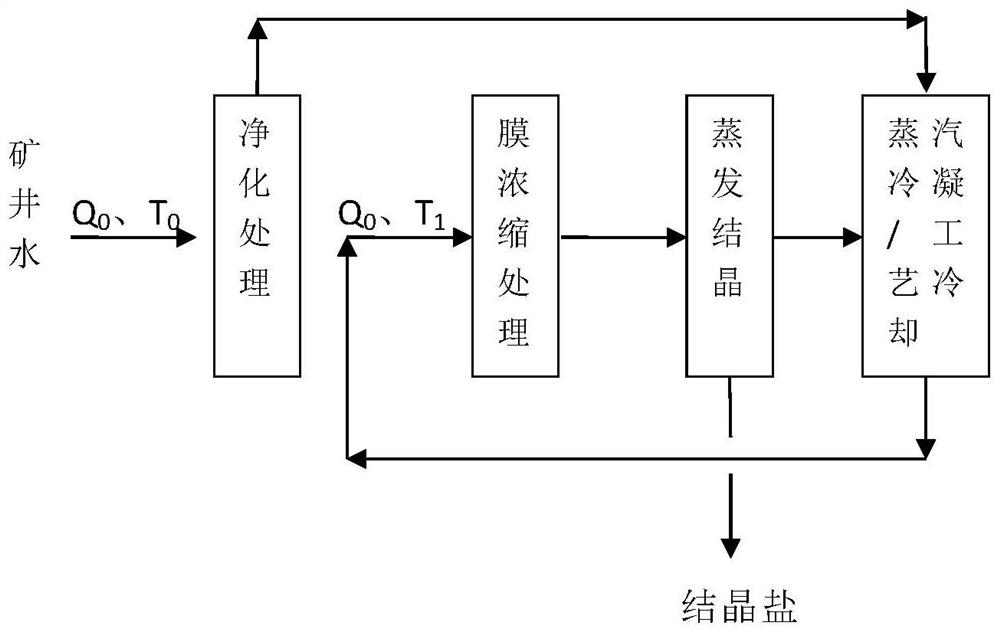

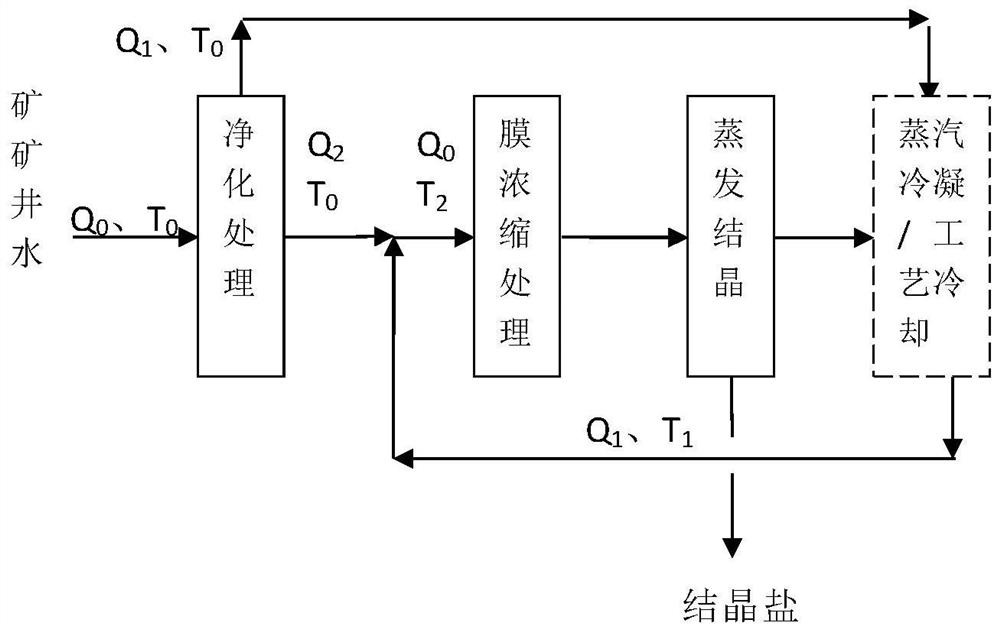

[0034] The core of the present invention is to provide an energy-saving and consumption-reducing method based on the whole process of zero discharge of mine water, which is called the first embodiment. The whole process of zero discharge of mine water includes purification treatment of mine water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com