Breeding excrement film grading biochemical treatment system and process

A technology of biochemical treatment and manure, which is applied in the field of animal husbandry, can solve problems such as odor emission, difficult slag discharge of biogas tanks, and difficult operation in winter, so as to improve the degree of ripening, reduce the concentration and residence time of effluent, and save construction and operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical features of the solution can be clearly described, and the solution will be described through specific implementation modes below.

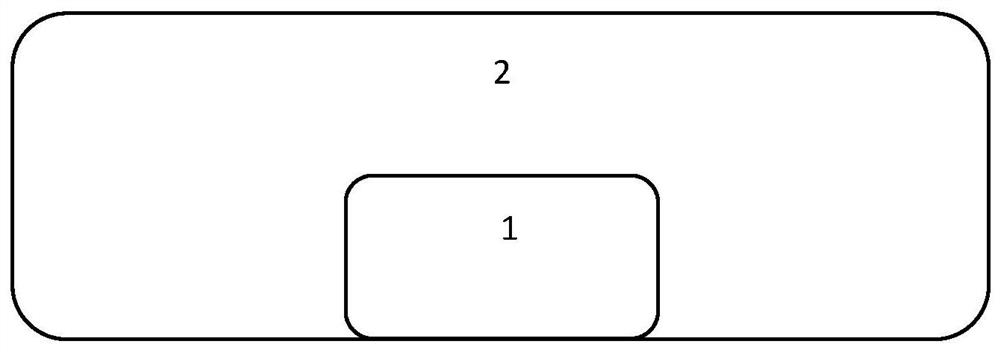

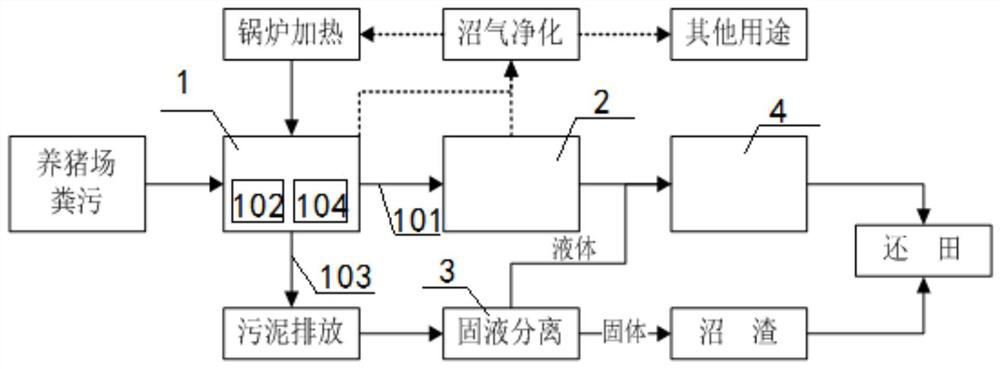

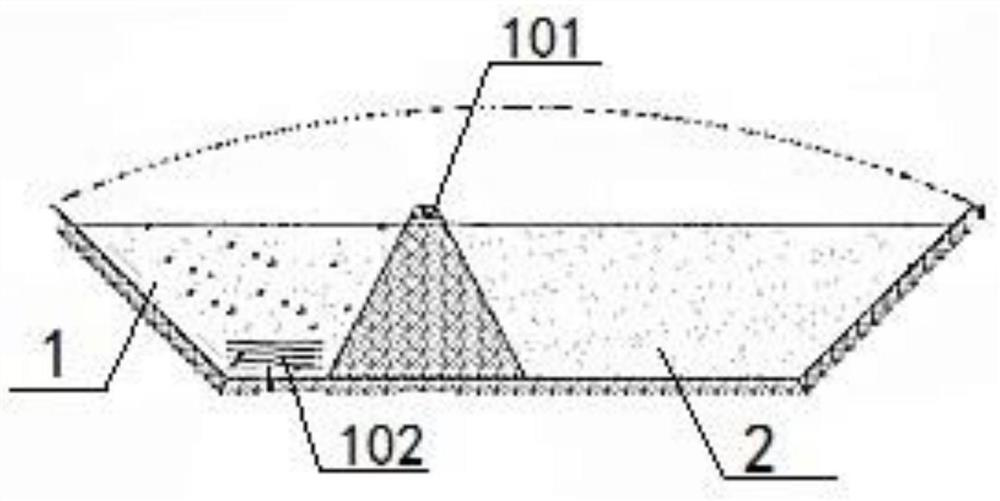

[0029] see Figure 1 to Figure 3 As shown, this embodiment is a biochemical treatment system for aquaculture manure membrane classification, including a first-level black film anaerobic pool 1 and a second-level black-film anaerobic pool 2, and the first-level black-film anaerobic pool 1 is located at the second-level black film anaerobic pool. In the anaerobic pool 2, the water temperature in the second-level black-film anaerobic pool 2 is significantly higher than the ambient temperature in winter, and it is wrapped outside the first-level black-film anaerobic pool 1, so it constitutes a thermal insulation barrier for the first-level black-film anaerobic pool 1. It is conducive to maintaining a higher temperature fermentation in the first-level black film anaerobic tank 1 to ensure higher fermentation efficiency.

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com