Process for preparing dexamethasone sodium phosphate by one-step method

A technology of dexamethasone sodium phosphate and step method, which is applied in the field of medicine, can solve the problems of long time, use of equipment and solvents, and cumbersome steps, and achieve the effects of simple method, reduced by-product generation, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

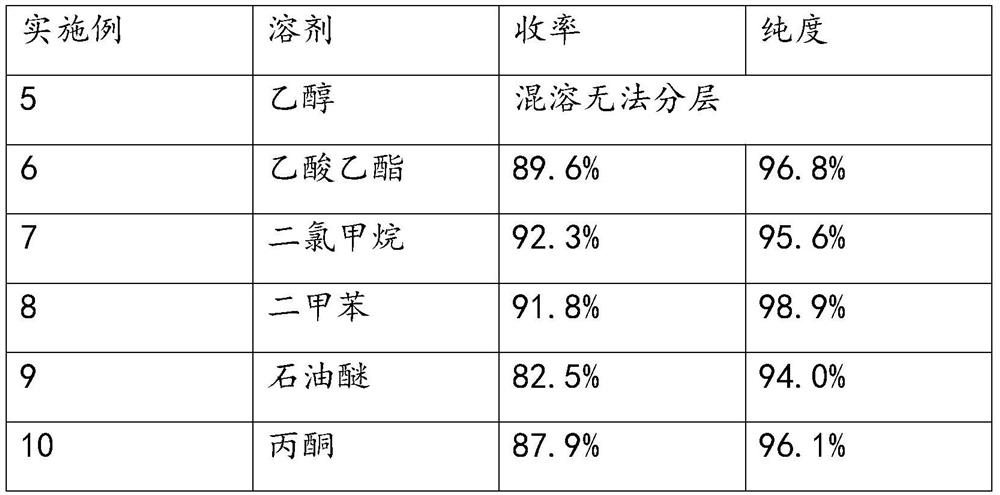

Examples

Embodiment 1

[0027] Add 2000ml of anhydrous tetrahydrofuran into the reaction tank, add 392g (1.0mol) of dexamethasone, stir and disperse, cool down to -50°C, add 755g (3.0mol) of pyrophosphoryl chloride dropwise, keep the temperature constant, after the addition is complete After reacting for 1 hour, take a sample to detect that the residual dexamethasone is ≤1.0%, add 1000ml of purified water for hydrolysis, slowly warm up to room temperature, and fully stir. After the hydrolysis is completed, add 1500ml of toluene, let stand to separate the phases, collect the oil phase, add dropwise sodium hydroxide solution to the toluene oil phase to adjust the pH to 10, let stand to separate the phases, collect the water phase, add activated carbon to the water phase for decolorization for 30 minutes, Filtrate, pour all the liquid into the clean area, add acetone crystals equal to the volume of sodium hydroxide solution, grow the crystals, centrifuge, and dry to obtain 415g of dexamethasone sodium ph...

Embodiment 2

[0029] Add 2000ml of anhydrous tetrahydrofuran into the reaction tank, add 392g (1.0mol) of dexamethasone, stir and disperse, cool down to -50°C, add 1007g (4.0mol) of pyrophosphoryl chloride dropwise, keep the temperature constant, after the addition is complete After reacting for 1 hour, take a sample to detect that the residual dexamethasone is ≤1.0%, add 1000ml of purified water for hydrolysis, slowly warm up to room temperature, and fully stir. After the hydrolysis is completed, add 1500ml of toluene, let stand to separate the phases, collect the oil phase, add dropwise sodium hydroxide solution to the toluene oil phase to adjust the pH to 10, let stand to separate the phases, collect the water phase, add activated carbon to the water phase for decolorization for 30 minutes, Filtrate, pour all the liquid into the clean area, add acetone crystals equal to the volume of sodium hydroxide solution, grow the crystals, centrifuge, and dry to obtain 445g of dexamethasone sodium p...

Embodiment 3

[0031] Add 2000ml of anhydrous tetrahydrofuran into the reaction tank, add 392g (1.0mol) of dexamethasone, stir and disperse, cool down to -50°C, add 1259g (5.0mol) of pyrophosphoryl chloride dropwise, keep the temperature constant, after the addition is complete After reacting for 1 hour, take a sample to detect that the residual dexamethasone is ≤1.0%, add 1000ml of purified water for hydrolysis, slowly warm up to room temperature, and fully stir. After the hydrolysis is completed, add 1500ml of toluene, let stand to separate the phases, collect the oil phase, add dropwise sodium hydroxide solution to the toluene oil phase to adjust the pH to 10, let stand to separate the phases, collect the water phase, add activated carbon to the water phase for decolorization for 30 minutes, Filtrate, pour all the liquid into the clean area, add acetone crystals equal to the volume of sodium hydroxide solution, grow the crystals, centrifuge, and dry to obtain 482g of dexamethasone sodium p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com