High-dosage rubber-plastic composite rubber powder modified asphalt and preparation method thereof

A technology of modified asphalt with high content, which is applied in building components, building insulation materials, buildings, etc., and can solve the problems of complex materials, high temperature performance, viscosity influence, low temperature performance influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] 1. Research on the preparation of rubber-plastic composite powder

[0022] In order to investigate the influence of the preparation process of rubber-plastic composite powder on rubber-plastic composite modified asphalt products, the inventors worked out the ratio of rubber-plastic composite powder (70-90 parts of waste tire rubber powder and 10-30 parts of waste plastic) In this paper, the parameters of the process conditions for the preparation of rubber-plastic composite powder by twin-screw extruder were studied.

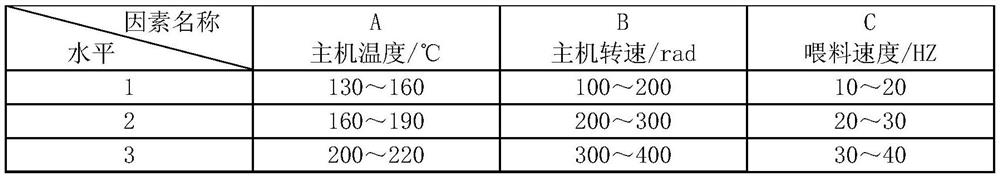

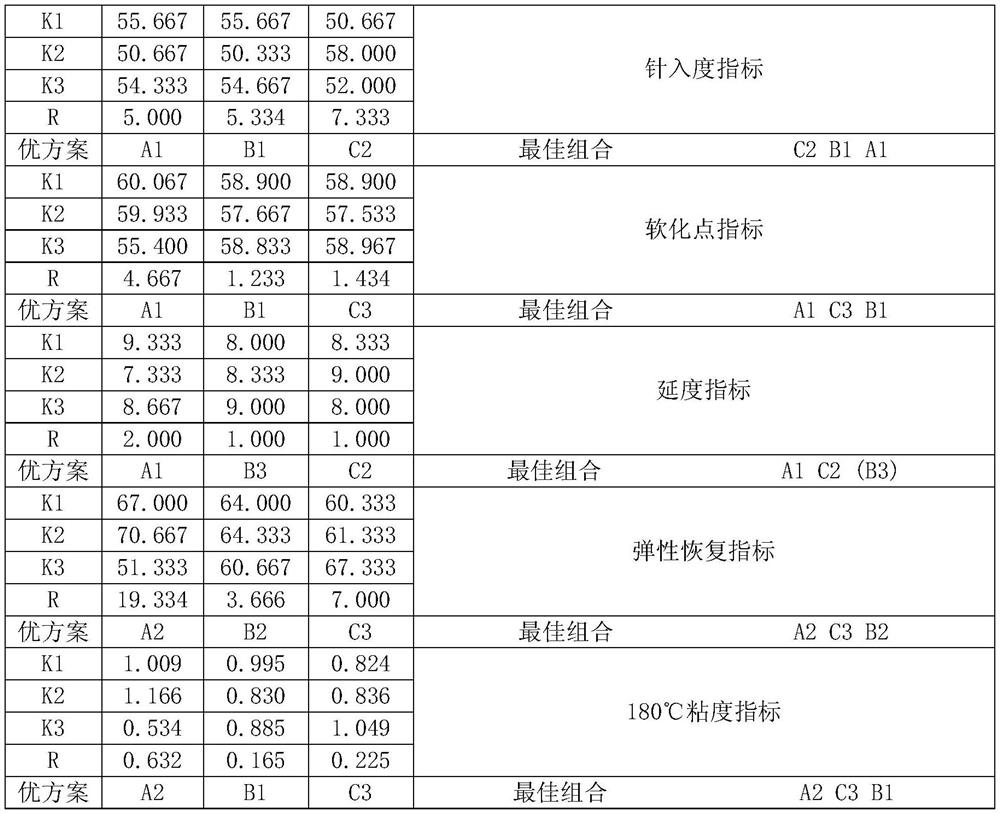

[0023] After investigation, it is found that the mechanical parameters of the twin-screw extruder are mainly affected by the heating temperature of the main engine, the rotational speed of the main engine and the feeding speed. By designing an orthogonal experiment with three factors and three levels (Table 1), and Appropriate mechanical parameters are determined by making modified asphalt from the prepared rubber powder (refer to the aforementioned formu...

Embodiment 1

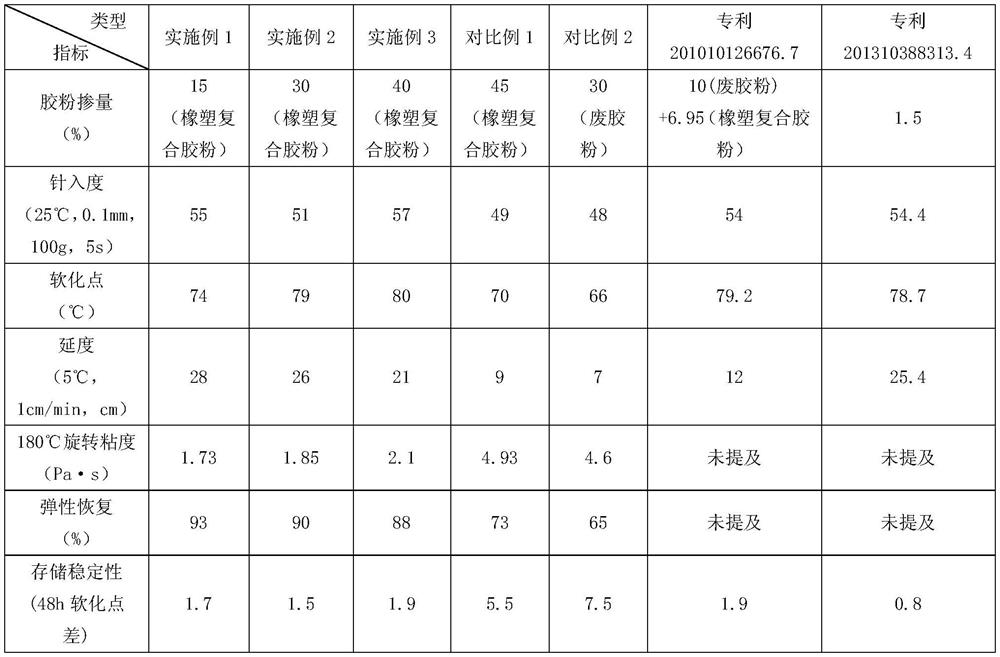

[0032] Step 1: Take 85 parts of waste tire rubber powder and 15 parts of HDPE and mix them evenly and pour them into the feeding bin of the twin-screw extruder. The temperature of the main machine is 160°C, the speed of the main machine is 200rad / min, and the feeding speed is 20hz. Extrude to obtain rubber-plastic composite powder, and pass through granulation equipment to make granules. Doped 15

[0033]Step 2: Take 500 parts of 70# base asphalt and heat it to a molten state, add 20 parts of furfural to extract oil, 10 parts of SBS modifier, 10 parts of SBR modifier, stir at a speed of 500rad / min for 0.5h, and then add 75 parts Rubber-plastic composite powder and 7.5 parts of sasobit were cut for 1 hour with a 5000rad / min high-speed shear. Finally, add 10 parts of sulfur stabilizer and continue stirring at 500rad / min for 0.5h to obtain rubber-plastic composite modified asphalt. The entire processing temperature is maintained at 180°C to 190°C.

Embodiment 2

[0035] Step 1: Take 85 parts of waste tire rubber powder and 15 parts of HDPE and mix them evenly and pour them into the feeding bin of the twin-screw extruder. The temperature of the main machine is 160°C, the speed of the main machine is 200rad / min, and the feeding speed is 20hz. Extrude to obtain rubber-plastic composite powder, and pass through granulation equipment to make granules.

[0036] Step 2: Take 500 parts of 70# base asphalt and heat it to a molten state, add 20 parts of furfural to extract oil, 10 parts of SBS modifier, 10 parts of SBR modifier, stir at 500rad / min for 0.5h, then add 150 parts Rubber-plastic composite powder and 7.5 parts of sasobit were cut for 1 hour with a 5000rad / min high-speed shear. Finally, add 10 parts of sulfur stabilizer and continue stirring at 500rad / min for 0.5h to obtain rubber-plastic composite modified asphalt. The entire processing temperature is maintained at 180°C to 190°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com