Water-resistant moisture-proof putty powder capable of defoaming and leveling as well as preparation method and use method thereof

A putty powder, energy-dissipating technology, applied in the direction of filling slurry, etc., can solve the problems of large air bubbles and pinholes, and achieve the effect of good effect and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

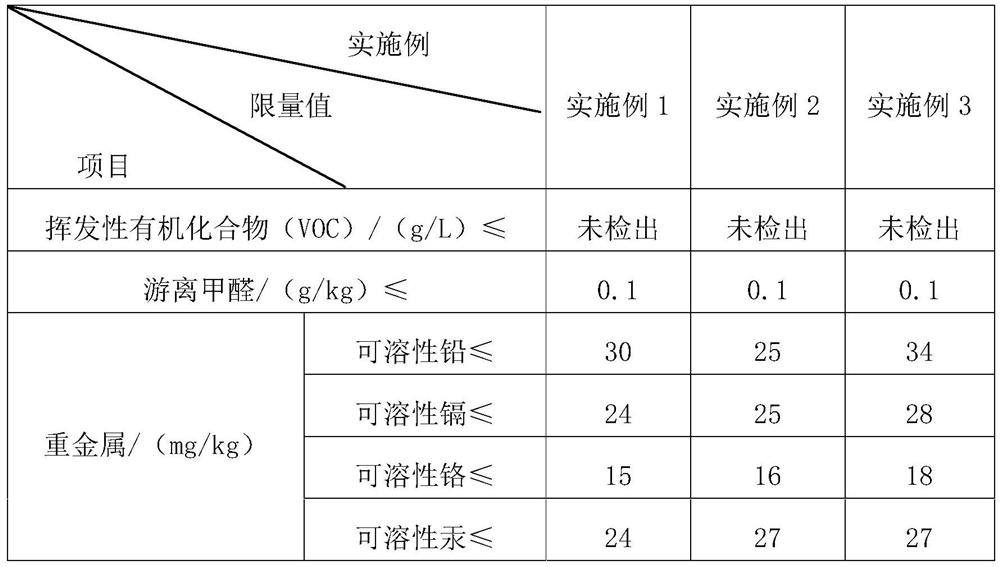

Embodiment 1

[0030] This embodiment provides a water-resistant and moisture-proof putty powder capable of defoaming and leveling, which is formed by mixing the following materials according to the mass ratio: 10 parts of Portland cement, 5 parts of calcium hydroxide, 10 parts of 40-mesh quartz sand, 10 parts of 70-mesh quartz sand, 20 parts of heavy calcium carbonate, 1 part of vitrified microbeads, 0.1 part of hydrogen ethyl cellulose, 1 part of lignin, 0.1 part of amylase and 0.5 part of crack-resistant fiber.

[0031] The preparation method of the above-mentioned water-resistant and moisture-proof putty powder capable of defoaming and leveling is firstly mixing Portland cement, 40-70 mesh quartz sand, vitrified microspheres, anti-cracking fiber and hydrogen propyl methylcellulose , and then mix 70-180 mesh quartz sand, heavy calcium carbonate, amylase, calcium hydroxide and lignin to obtain a water-resistant and moisture-proof putty powder capable of defoaming and leveling. Among them, ...

Embodiment 2

[0034] This embodiment provides a water-resistant and moisture-proof putty powder capable of defoaming and leveling, which is formed by mixing the following materials according to the mass ratio: 20 parts of Portland cement, 15 parts of calcium hydroxide, 30 parts of 70-mesh quartz sand, 30 parts of 180-mesh quartz sand, 30 parts of heavy calcium carbonate, 10 parts of vitrified microbeads, 0.5 parts of hydrogen ethyl cellulose, 10 parts of lignin, 1.0 part of amylase and 2.0 parts of anti-cracking fiber.

[0035] The preparation method of the above-mentioned water-resistant and moisture-proof putty powder capable of defoaming and leveling is firstly mixing Portland cement, 40-70 mesh quartz sand, vitrified microspheres, anti-cracking fiber and hydrogen propyl methylcellulose , and then mix 70-180 mesh quartz sand, heavy calcium carbonate, amylase, calcium hydroxide and lignin to obtain a water-resistant and moisture-proof putty powder capable of defoaming and leveling. Among ...

Embodiment 3

[0038] This embodiment provides a water-resistant and moisture-proof putty powder capable of defoaming and leveling, which is formed by mixing the following materials according to the mass ratio: 15 parts of Portland cement, 10 parts of calcium hydroxide, 20 parts of 60-mesh quartz sand, 20 parts of 100 mesh quartz sand, 25 parts of heavy calcium carbonate, 5 parts of vitrified microbeads, 0.3 parts of hydrogen ethyl cellulose, 5 parts of lignin, 0.8 parts of amylase and 1 part of anti-cracking fiber.

[0039]The preparation method of the above-mentioned water-resistant and moisture-proof putty powder capable of defoaming and leveling is firstly mixing Portland cement, 40-70 mesh quartz sand, vitrified microspheres, anti-cracking fiber and hydrogen propyl methylcellulose , and then mix 70-180 mesh quartz sand, heavy calcium carbonate, amylase, calcium hydroxide and lignin to obtain a water-resistant and moisture-proof putty powder capable of defoaming and leveling. Among them,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com