Fluff type phosphating process for steel plate

A phosphating and steel plate technology, applied in the direction of metal material coating process, etc., can solve the problems of insufficient adhesion, limited improvement of workpiece adhesion, equipment damage, etc., to improve strength, improve adhesion, improve Effect of Surface Bonding Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

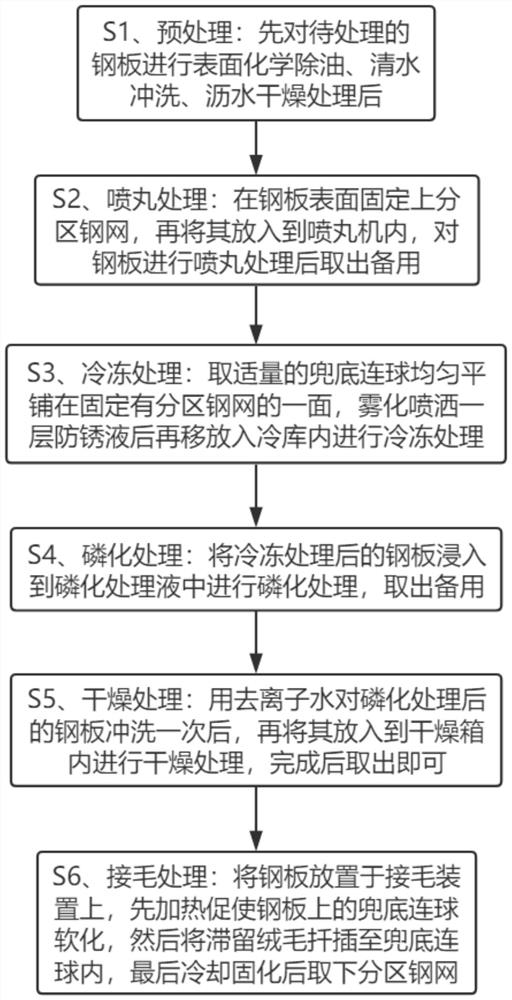

[0045] see figure 1 , a fluff type phosphating process for a steel plate, comprising the following steps:

[0046] S1. Pretreatment: firstly carry out chemical degreasing on the surface of the steel plate to be treated, rinse with clean water, drain and dry;

[0047] S2, shot peening treatment: fix the partitioned steel mesh 9 on the surface of the steel plate, then put it into the shot blasting machine, carry out shot peening treatment on the steel plate and take it out for later use;

[0048] S3. Freezing treatment: take an appropriate amount of pocket balls 7 and evenly spread them on the side where the partitioned steel mesh 9 is fixed, atomize and spray a layer of anti-rust liquid, then transfer to the cold storage for freezing treatment, and keep the freezing temperature at -5 ℃, after freezing for 3 hours, take it out for use. The anti-rust solution is made by mixing anti-rust agent and water according to the mass ratio of 1:30;

[0049] S4. Phosphating treatment: imm...

Embodiment 2

[0059] see figure 1 , a fluff type phosphating process for a steel plate, comprising the following steps:

[0060] S1. Pretreatment: firstly carry out chemical degreasing on the surface of the steel plate to be treated, rinse with clean water, drain and dry;

[0061] S2, shot peening treatment: fix the partitioned steel mesh 9 on the surface of the steel plate, then put it into the shot blasting machine, carry out shot peening treatment on the steel plate and take it out for later use;

[0062] S3. Freezing treatment: take an appropriate amount of pocket balls 7 and evenly spread them on the side where the partitioned steel mesh 9 is fixed, atomize and spray a layer of anti-rust liquid, then transfer to the cold storage for freezing treatment, and keep the freezing temperature at -6 ℃, after 3.5 hours of freezing treatment, take it out for use, the anti-rust liquid is made by mixing anti-rust agent and water according to the mass ratio of 1:32;

[0063] S4. Phosphating treat...

Embodiment 3

[0070] see figure 1 , a fluff type phosphating process for a steel plate, comprising the following steps:

[0071] S1. Pretreatment: firstly carry out chemical degreasing on the surface of the steel plate to be treated, rinse with clean water, drain and dry;

[0072] S2, shot peening treatment: fix the partitioned steel mesh 9 on the surface of the steel plate, then put it into the shot blasting machine, carry out shot peening treatment on the steel plate and take it out for later use;

[0073] S3. Freezing treatment: take an appropriate amount of balls 7 and evenly spread them on the side where the partitioned steel mesh 9 is fixed, atomize and spray a layer of anti-rust liquid, then transfer to the cold storage for freezing treatment, and keep the freezing temperature at -8 ℃, take it out after freezing for 4 hours, and use it for later use. The anti-rust solution is made by mixing anti-rust agent and water according to the mass ratio of 1:35;

[0074] S4. Phosphating trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com