Prestress full-length anchoring mortar anchor rod for underground cave depot and rapid anchoring tensioning method

A full-length anchoring and mortar bolt technology, which is applied in the field of construction engineering, can solve the problems of long time consumption, poor anchoring effect of full-length anchoring bolts, complicated installation procedures, etc., and achieves short time consumption, simple installation procedures, and stress diffusion range. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

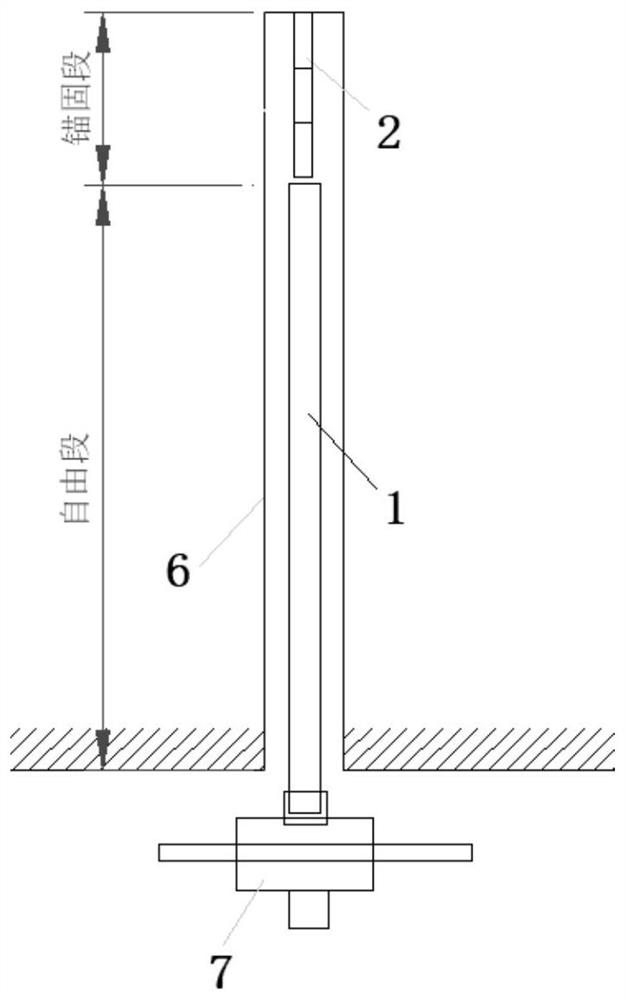

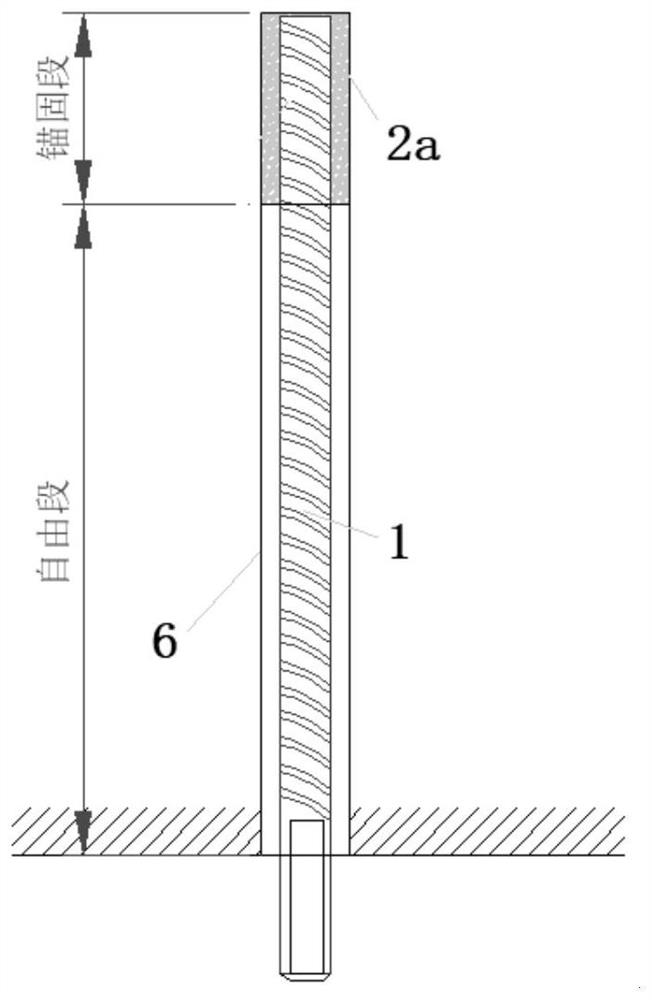

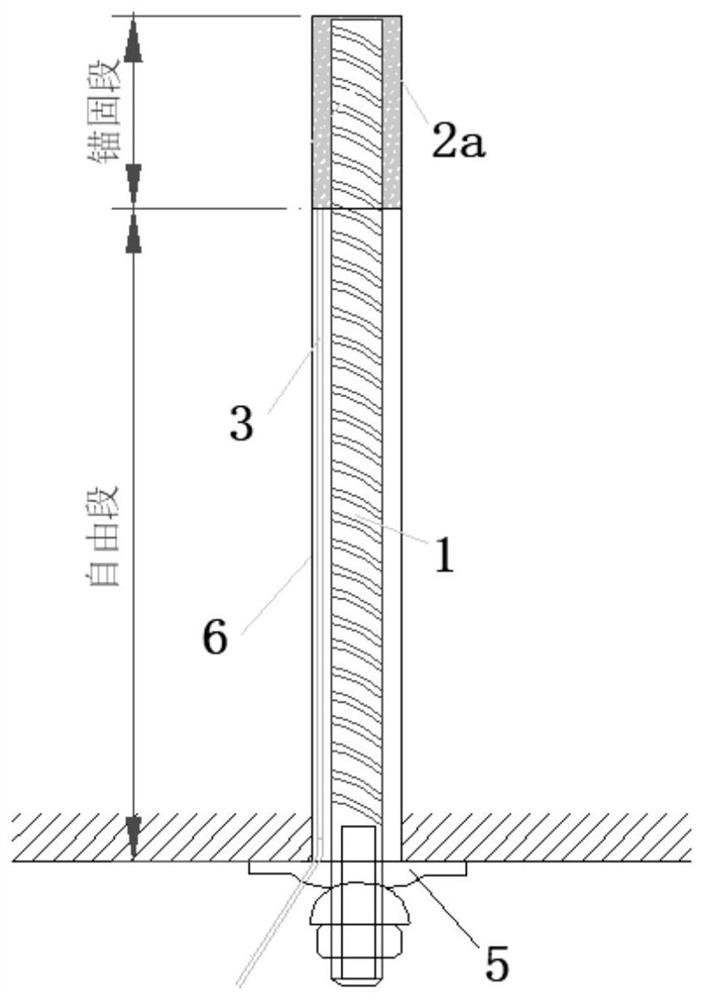

[0022] combine figure 1 — Figure 5 As shown, a prestressed full-length anchoring mortar bolt for underground caverns mainly consists of a full-length bolt body 1, a resin medicine coil 2, an exhaust pipe 3, a grouting pipe 4 and an anchor backing plate 5.

[0023] Resin drug roll 2 is located at the bottom of borehole 6 and is used for anchoring at the end of full-length anchor rod body 1 after being smashed as an anchor segment, and resin drug roll 2 is used as a resin anchoring agent at the end of full-length anchor rod body 1 . The tail end of the full-length anchor rod body 1 is installed on the mouth of the borehole 6 through the anchor pad 5 for prestressed tension. It is used for grouting and anchoring of the free section, and the exhaust pipe 3 is used for grouting and exhausting of the free section. 4 Mortar anchoring is formed after grouting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com