An Automatic Control Method of Oven Temperature Based on Slope Signal

A ramp signal and furnace temperature technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of large fluctuations in furnace temperature, temperature rise, disadvantages, etc., to reduce labor intensity, improve oven quality, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

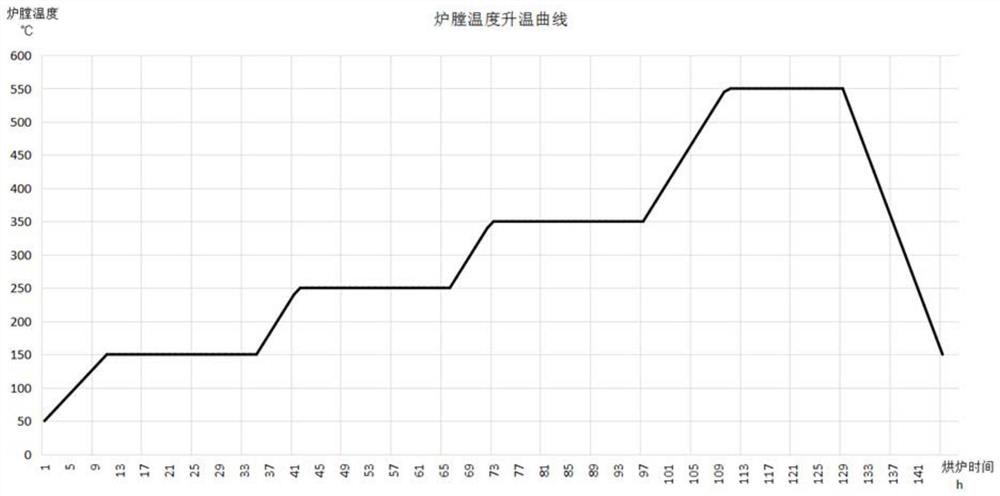

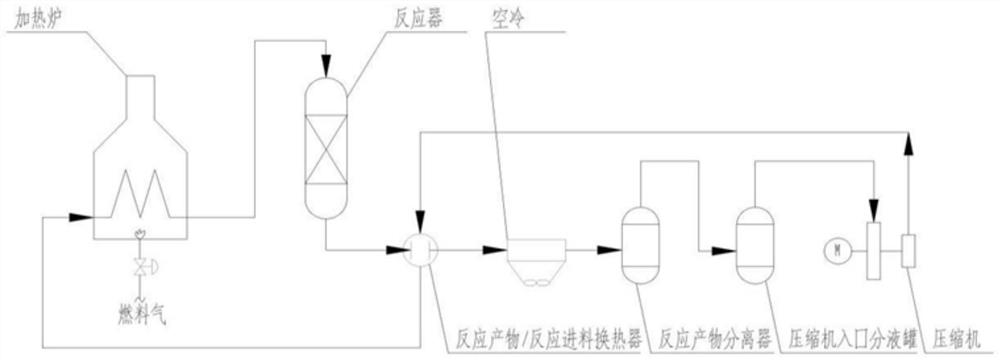

[0038] Embodiment 1: as Figure 1-5 Shown is a specific embodiment of a method for automatically controlling the temperature of an oven based on a ramp signal. This embodiment is a method for automatically controlling the temperature of an oven based on a ramp signal. It is characterized in that it includes the following steps:

[0039] Step 1): Install a Furnace A temperature transmitter TE1A, A Furnace temperature transmitter TE1A configures a Furnace A temperature controller TIC1A (PID adjustment module 1) to form the main loop of the control system, on the A furnace fuel gas pipeline There is a secondary circuit of the control system. The secondary circuit of the control system includes the A furnace fuel gas flow sensor FE1A (orifice plate) installed on the A furnace fuel gas pipeline, the A furnace fuel gas flow transmitter FT1A (differential pressure transmitter), A The furnace fuel gas flow regulating valve FV1A and the A furnace fuel gas flow controller FIC1A (PID adj...

Embodiment 2

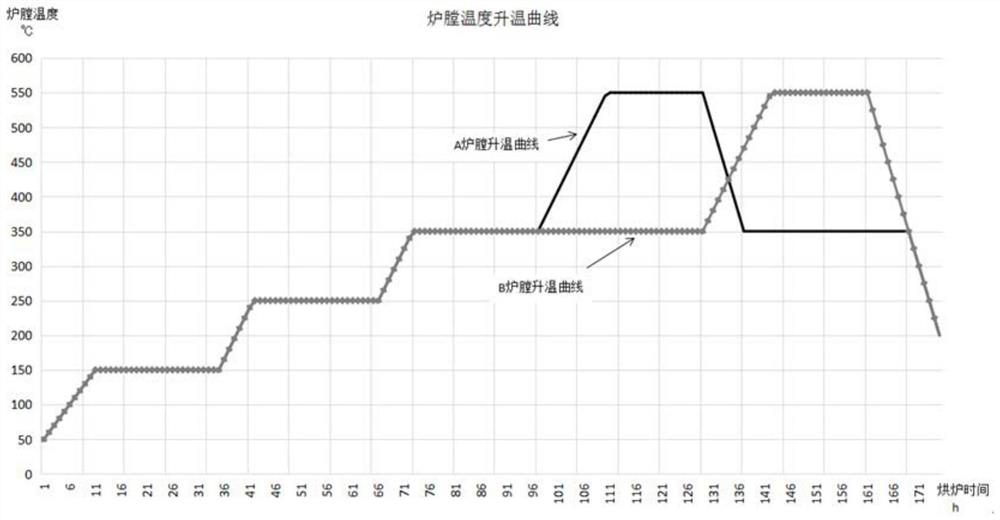

[0045] Embodiment 2: as Figure 1-5 Shown is a specific embodiment of a method for automatically controlling the temperature of an oven based on a ramp signal. This embodiment is a method for automatically controlling the temperature of an oven based on a ramp signal. It is characterized in that it includes the following steps:

[0046] Step 1): Install a B furnace temperature transmitter TE1B, B furnace temperature transmitter TE1B configure a B furnace temperature controller TIC1B (PID adjustment module 3) to form the main loop of the control system, on the B furnace fuel gas pipeline A control system sub-loop is provided, and the control system sub-loop includes the B furnace fuel gas flow sensor FE1B (orifice plate) installed on the B furnace fuel gas pipeline, the B furnace fuel gas flow transmitter FT1B (differential pressure transmitter), and the B furnace fuel gas flow transmitter FT1B (differential pressure transmitter). The furnace fuel gas flow regulating valve FV1B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com