Image focusing method of femtosecond laser system

A technology of femtosecond laser and system image, which is applied in the field of femtosecond laser system image focusing, to achieve the effect of simple operation steps, easy construction and use, and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

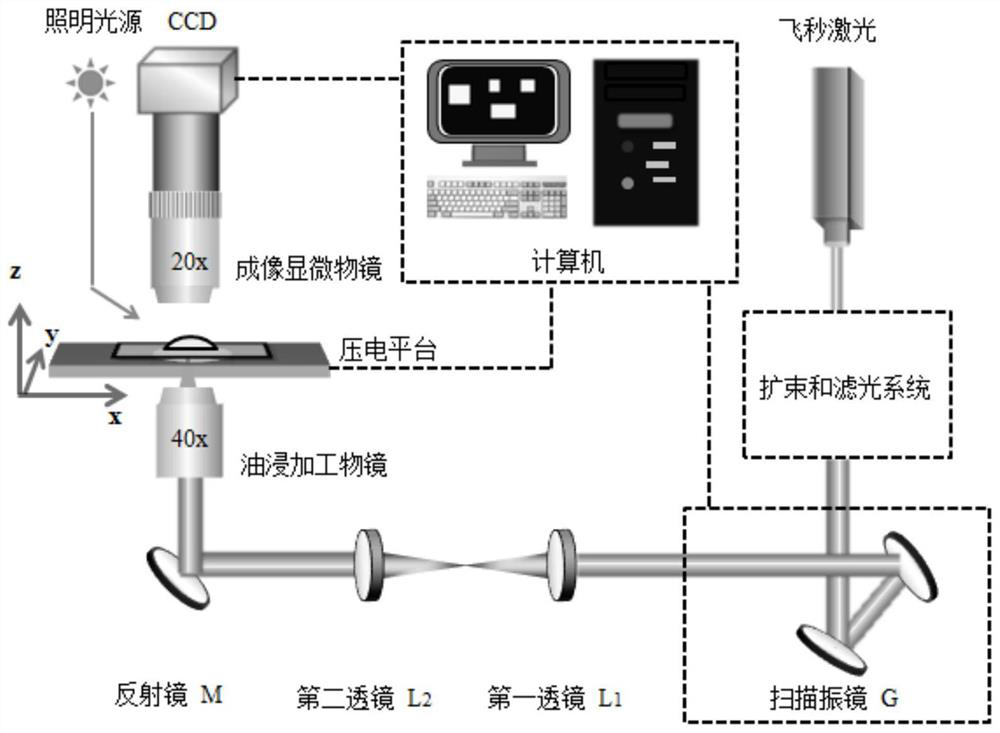

Method used

Image

Examples

Embodiment 1

[0040] In the processing optical path of the femtosecond laser system, the laser focusing point on the substrate surface is found by the scratch method.

[0041] After the substrate is cleaned and glued, it is fixed on the processing platform, and ink marks are made on the non-glue area with a marker pen. Based on the femtosecond laser system to process the optical path, adjust the z-axis position of the microscope so that the laser can carve scratches on the ink marks. Repeat this operation until the light spot draws a uniform and uninterrupted continuous scratch on the ink mark, which indicates that the photolithography microscope focuses the laser spot on the upper surface of the substrate.

[0042] In the processing optical path of the femtosecond laser system, the laser focus point on the substrate surface is found by the scratch method. The specific steps are as follows:

[0043] (1), processing sample preparation:

[0044] The specific steps are as follows: wipe the m...

Embodiment 2

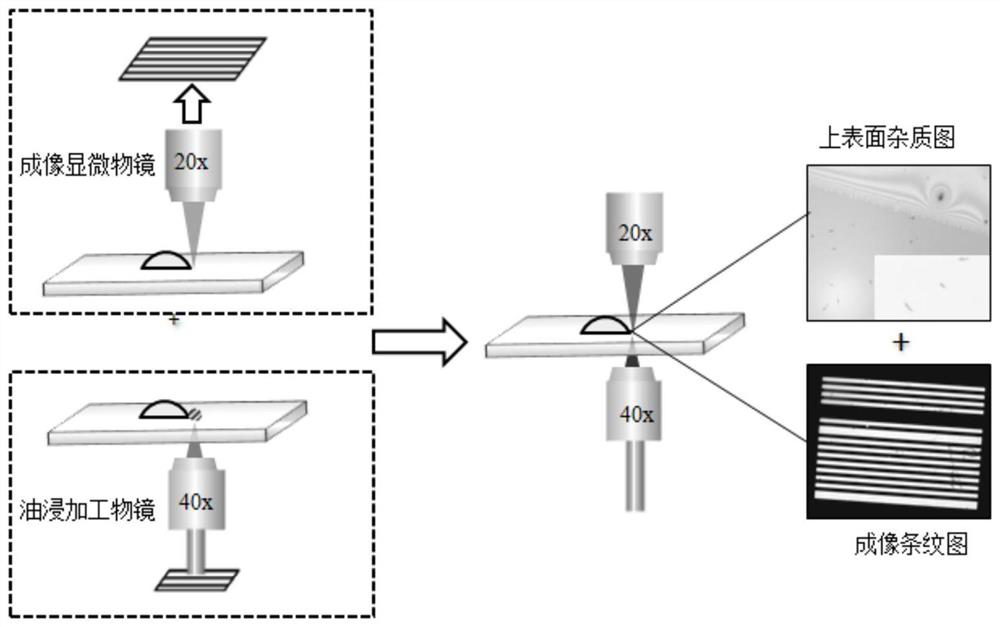

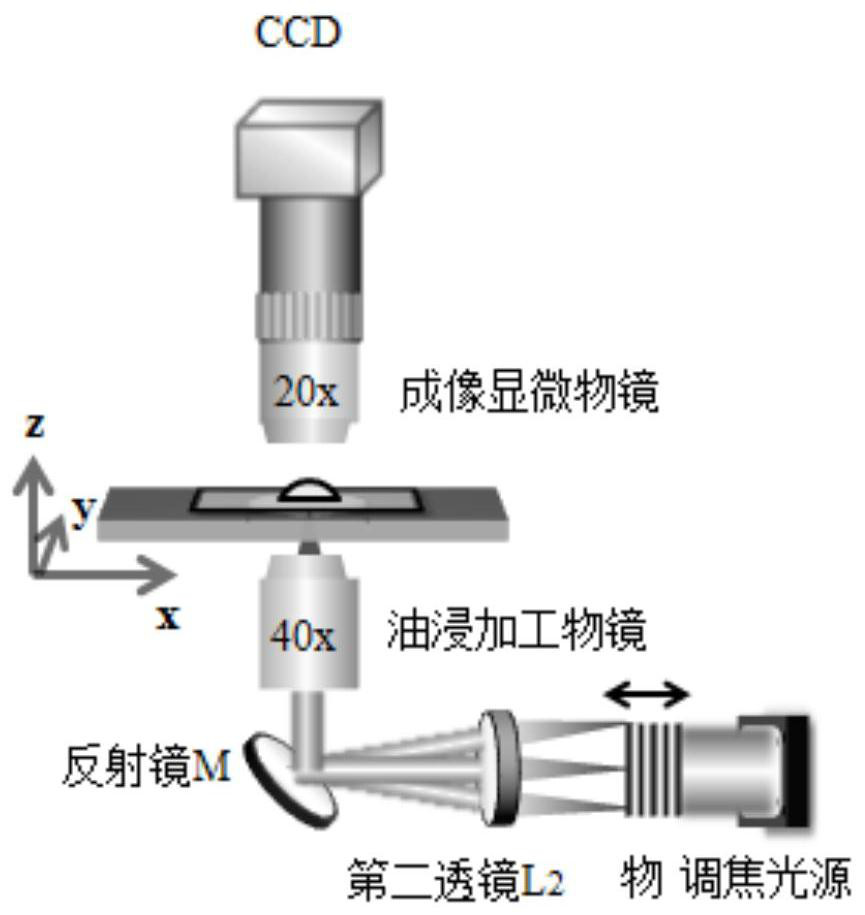

[0051] The cylindrical test structure is processed by the femtosecond laser system image focusing method.

[0052] After finding the focus position of the laser spot by means of the laser across the ink marks on the surface of the substrate, and then based on this position, determine and fix the corresponding position of the object in the focusing optical path, and indirectly reflect the focus state of the laser with the clarity of the imaging state. If the CCD is at the same position, both a clear substrate surface and a clear fringe image can be observed, indicating that the focus is accurate. In subsequent processing, in order to make up for the height difference between different substrates, it is only necessary to fine-tune the z-direction position of the processing objective lens to make the fringes clear, then find the focal plane position and start processing. After the processing is completed, the substrate is processed and the processing results are analyzed.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com